Design your own Dual Spring-Rate Coilovers

#1

Pro

Thread Starter

Join Date: Jun 2005

Location: Napa Valley, CA

Posts: 589

Likes: 0

Received 0 Likes

on

0 Posts

I. What they are and why they are needed:

Last year I started a thread when I started playing around with tender springs and experimenting with my first dual spring coilover system. In that thread I wrote the following:

For all of you out there with upgraded Koni Yellow shocks and stiffer coil over springs. Have you ever thought,

“Man I like how the car handles the twisties with the upgraded springs, but man this thing just feels way too primitive on the streets, I mean it handles the potholes, bumps, and ruts like an old wild west chuck wagon. I mean, it’s a Porsche for crying out loud, shouldn’t it be a little more civilized?”

Well, maybe that’s a little exaggerated, but not by much. Anyway, that’s how I felt after driving around these old Napa Valley back roads with upgraded #350 front springs for over a year now. The ride was not horrible, but in comparison to my Mercedes Benz commute car, I was simply not satisfied with how primitive the 951 suspension felt.

Since I had already spent money on Koni Yellows, I decided to make to most of what I already had and improve the suspension system. Although I am using Koni Yellows as a starting point, any adjustable strut should do just fine.

This year's design has been more than satisfying…in fact, for a mere $272 it is down right mind blowing awesome!

II. What can it do? – Street - Rain - Race track

Well, I am so impressed with this set-up that think I’m going to call it the “Wolf in sheep’s clothing” suspension set-up. It has surpasses all my expectations!!!

In street mode. The car ride is very comfortable, the suspension is extremely compliant over potholes, street ruts, and road bumps. It basically feels as comfortable as your stock 951 suspension. Except that, on simulated back road twisties, the car has practically no simulated body roll. No matter how hard it is tossed into the corners, the suspension provides a very stable platform, yet compliant to all road irregularities, the best feeling in the world.

For this set-up to work properly it is necessary to use a stiff enough tender spring that is NOT fully collapsed under the car’s normal weight. I am using a 4” free length 350# tender which incidently still has 5/8” of travel available under its installed height of 2.0 inches. This is just enough to act as a “shock absorber” and soften the impact to the main 550# spring whenever road irregularities are encountered. However, after that initial slack is taken up, it’s all up to the 550# main spring to resist the effects of weight transfer and hold body roll at bay.

Now the beauty of a dual spring set-up is that under the softer initial “combo spring rate”, the damper settings can be set as soft as desired. This is one of the major benefits that helps do the trick. Damper rates can be set as soft as ZERO rebound adjustment turns and the Koni’s damping forces are still good enough to provide critical damping for this spring package.

A stiff single spring system cannot be tamed like this. I tried setting ZERO rebound when I had my suspension mocked-up using only the 550# main spring, and yes the ride quality was good on potholes, but after a number of potholes the car was bouncing up and down the road like a pogo stick. At soft rebound settings the Koni’s damping cannot control the stiff 550# spring. Also, going over bumps, even with zero bump setting, the oomph!!! transmitted to the driver and passenger, is simply unacceptable. Increase the damper stiffness to control the 550# springs, and now we are back to a primitive suspension that is not comfortable any longer.

Rain, rain, rain…. We have had lots of rain here in the valley, especially in month of February. This gave me a great opportunity to take the car out and see how the suspension dealt with slippery roads. I have only two words to say about it - Confidence Inspiring. Being able to set the damper settings at very soft settings greatly improves the cars wet traction performance (having new Fuzion ZRi’s doesn’t hurt either).

“Race Mode”. A second major design parameter for this system was to design a suspension that did not bottom out during heavy cornering at race track speeds. Ever since I learned here on Rennlist that a number Rennlisters had discovered that their 951’s were riding on the bump stops while heavy cornering (especially lowered cars with sticky tires) at race track events, I decided to experiment with my car and see for myself if my car was bottoming out also. It was very simple to do. I simply placed a zip tie on the strut shaft went for a few laps around Infineon race track avoiding rough pavement and avoiding the apex and trackout berms. When I came back, I removed the wheel and looked for the zip tie. It had been pushed up way into the bump stop. Well I was very disappointed to say the least.

However, this gave me the motivation to undertake this winter design project. I started out with a clean sheet of paper and decided to go back to basic physics and figure out what forces where at play here, and what would be the minimum spring stiffness necessary to keep the suspension working freely - unobstructed. All spring math calculations, measurements, and estimates will follow shortly in a follow up post.

Track time!!!

Slapped on some Toyo RA-1’s, Hawk HT-10 racing pads, set camber close to – 3 deg., set 1/16” toe out, Koni’s to 1 ½ turns firm, and headed to Infineon Raceway just 20 minutes away.

I went to the NASA DE at Infineon Raceway on March 21, 2009. The car was so easy to drive, it put a big grin on my face the entire day. Turn-in response has been greatly improved. The car turns in so obediently and does not roll much even under heavy trail braking scenarios. What was most apparent was how well it behaved at this track’s signature section, the Infineon esses, an absolute blast, again this dual spring suspension set-up has exceeded all my expectations.

One would think that with 550# front main springs and mere 28 mm rear torsion bars, the car would push like a pig, but NOT so!!!! The esses section is a great place to evaluate the car’s turn-in response as one modulates the throttle, and the hairpin turn at the end of the back straight a great place to evaluate the degree of inherent understeer.

Braking Zone. Go up to 120+ mph on the back straight on the approach to Turn #11 (the hairpin) and stomp on the brakes. The brakes are much easier to modulate over the undulating payment. Last year with the 350# springs there were some spots where the car used to bottom out under this heavy braking condition, the screech of tires, and flat spots soon followed as the tires searched for grip over the bumps.

This is a favorite passing zone for the really fast guys. This braking zone has to be respected the most, however, because of the proximity of outer a wall and the lack of run off area. However, lots of braking battles occur here and the only winners seem to be the flatbed tow trucks, they seem to conduct a lot of business at Turn 11.

I was also pleasantly surprised how well I could navigate through the downhill Turn #4. This turn has in the past given me problems, because with a downhill braking zone, and a greater than 90 degree off-camber right turn, the front outside spring would tend bottom out at turn-in and the car would tend to “push” no matter how much trail braking I dared to dial in - a tad too much trail braking and get ready for the spin!!! NOW, with the 550# main springs, what a difference, I like Turn 4. Easy as pie.

In summary, this suspension set up is perfect for a heavy street car, i.e. one that sees dual purpose Street/DE car.

The only thing I didn’t get to do on 3/21/09, was get a good clean lap in order to compare to last year’s 2:01 times. This was because the track was so crowded. NASA combined the Time Trialers (TT’s) with the HPDE-4 group into one session, with so many cars on track at the same time, there was just too much traffic, but on the upside, it gave me a good opportunity to practice passing. YMMV

Baseline: Koni Yellow struts, #350 x 10” front springs, and adjustable ride height kit. Not a good street/track compromise.

So the revised suspension.

Upgrade #2: dual spring package (2 ½” ID springs):

Hypercoil 8” x 550# main spring

Hypercoil Stacked Spring Divider,

Hypercoil 4” x 350# (tender spring)

PitstopUSA.com

2 550# Main Springs = HYPCO8-550 = $108

2 350# Tender Springs = HYPCO4-350= $108

2 Spring Dividers = HY-18DS100 = $56

Sub Total = $272

Upgrade #3 (Although not necessary, but for the more ambitious in the crowd, one can also convert to Koni Dual Adjustable Race Struts)

Summit Racing.com

Koni Race Yellows dual adjustable #8611-1259

2 Koni Race Struts = KON-86111259RACE = $620

Sub Total = $892.00

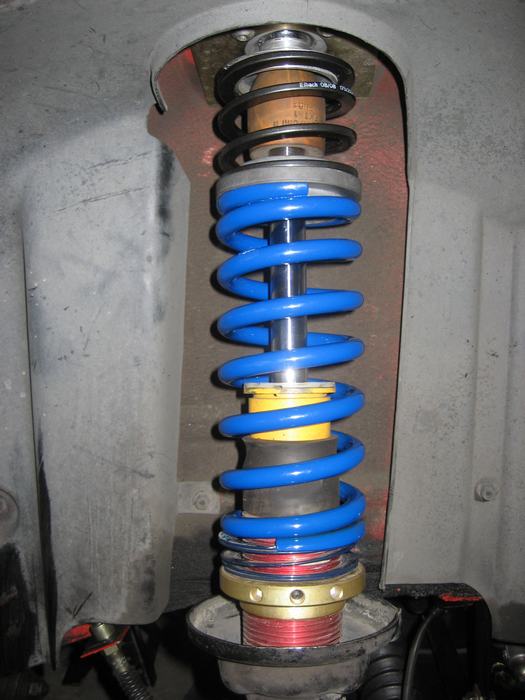

2.5” ID Dual Spring Combo (4” 350#Tender + 8” 550#Main)

The combined spring rate constant is calculated as follows: 1/Cf = 1/C1 + 1/C2

Initial combo rate = 214 lb/in.

In the picture below, you can see the adjustable height aluminum sleeve after being cut XX” (Do as I say, not as I do. Measure twice, cut only once.)

It is necessary to cut the threaded sleeve so that the spring separator (slider) can slide up and down above the spring perch on the smooth portion of the strut tube.

I highly recommend that suspension be mocked-up, wrap tape around the threaded collar to protect the threads (since one cannot use the spring slider at this point), assemble the dual spring combo and drive around for a week or two to let the suspension settle. Then take final measurements and cut the necessary threads off the aluminum threaded collar.

Depicted in the middle. Hypercoil spring Divider/slider HY-18DS100.

All the parts needed:

The assembled package - at full droop. The scratches seen is where the plastic slider is rubbing off the black painted tube.

Coming Soon, in a few days….

Section III. How to Design your own Dual Spring Rate Coilover suspension

(all measurements, specs, formulas, and estimates) - See post #24.

Section IV, "Lowering the car to improve cornering potential” - See post #35

Section V. Converting Single Adjustable Koni Yellows to Dual Adjustable (Bump and Rebound) Race Koni’s - see post #37

This has been a really fun project.

Last year I started a thread when I started playing around with tender springs and experimenting with my first dual spring coilover system. In that thread I wrote the following:

For all of you out there with upgraded Koni Yellow shocks and stiffer coil over springs. Have you ever thought,

“Man I like how the car handles the twisties with the upgraded springs, but man this thing just feels way too primitive on the streets, I mean it handles the potholes, bumps, and ruts like an old wild west chuck wagon. I mean, it’s a Porsche for crying out loud, shouldn’t it be a little more civilized?”

Well, maybe that’s a little exaggerated, but not by much. Anyway, that’s how I felt after driving around these old Napa Valley back roads with upgraded #350 front springs for over a year now. The ride was not horrible, but in comparison to my Mercedes Benz commute car, I was simply not satisfied with how primitive the 951 suspension felt.

Since I had already spent money on Koni Yellows, I decided to make to most of what I already had and improve the suspension system. Although I am using Koni Yellows as a starting point, any adjustable strut should do just fine.

This year's design has been more than satisfying…in fact, for a mere $272 it is down right mind blowing awesome!

II. What can it do? – Street - Rain - Race track

Well, I am so impressed with this set-up that think I’m going to call it the “Wolf in sheep’s clothing” suspension set-up. It has surpasses all my expectations!!!

In street mode. The car ride is very comfortable, the suspension is extremely compliant over potholes, street ruts, and road bumps. It basically feels as comfortable as your stock 951 suspension. Except that, on simulated back road twisties, the car has practically no simulated body roll. No matter how hard it is tossed into the corners, the suspension provides a very stable platform, yet compliant to all road irregularities, the best feeling in the world.

For this set-up to work properly it is necessary to use a stiff enough tender spring that is NOT fully collapsed under the car’s normal weight. I am using a 4” free length 350# tender which incidently still has 5/8” of travel available under its installed height of 2.0 inches. This is just enough to act as a “shock absorber” and soften the impact to the main 550# spring whenever road irregularities are encountered. However, after that initial slack is taken up, it’s all up to the 550# main spring to resist the effects of weight transfer and hold body roll at bay.

Now the beauty of a dual spring set-up is that under the softer initial “combo spring rate”, the damper settings can be set as soft as desired. This is one of the major benefits that helps do the trick. Damper rates can be set as soft as ZERO rebound adjustment turns and the Koni’s damping forces are still good enough to provide critical damping for this spring package.

A stiff single spring system cannot be tamed like this. I tried setting ZERO rebound when I had my suspension mocked-up using only the 550# main spring, and yes the ride quality was good on potholes, but after a number of potholes the car was bouncing up and down the road like a pogo stick. At soft rebound settings the Koni’s damping cannot control the stiff 550# spring. Also, going over bumps, even with zero bump setting, the oomph!!! transmitted to the driver and passenger, is simply unacceptable. Increase the damper stiffness to control the 550# springs, and now we are back to a primitive suspension that is not comfortable any longer.

Rain, rain, rain…. We have had lots of rain here in the valley, especially in month of February. This gave me a great opportunity to take the car out and see how the suspension dealt with slippery roads. I have only two words to say about it - Confidence Inspiring. Being able to set the damper settings at very soft settings greatly improves the cars wet traction performance (having new Fuzion ZRi’s doesn’t hurt either).

“Race Mode”. A second major design parameter for this system was to design a suspension that did not bottom out during heavy cornering at race track speeds. Ever since I learned here on Rennlist that a number Rennlisters had discovered that their 951’s were riding on the bump stops while heavy cornering (especially lowered cars with sticky tires) at race track events, I decided to experiment with my car and see for myself if my car was bottoming out also. It was very simple to do. I simply placed a zip tie on the strut shaft went for a few laps around Infineon race track avoiding rough pavement and avoiding the apex and trackout berms. When I came back, I removed the wheel and looked for the zip tie. It had been pushed up way into the bump stop. Well I was very disappointed to say the least.

However, this gave me the motivation to undertake this winter design project. I started out with a clean sheet of paper and decided to go back to basic physics and figure out what forces where at play here, and what would be the minimum spring stiffness necessary to keep the suspension working freely - unobstructed. All spring math calculations, measurements, and estimates will follow shortly in a follow up post.

Track time!!!

Slapped on some Toyo RA-1’s, Hawk HT-10 racing pads, set camber close to – 3 deg., set 1/16” toe out, Koni’s to 1 ½ turns firm, and headed to Infineon Raceway just 20 minutes away.

I went to the NASA DE at Infineon Raceway on March 21, 2009. The car was so easy to drive, it put a big grin on my face the entire day. Turn-in response has been greatly improved. The car turns in so obediently and does not roll much even under heavy trail braking scenarios. What was most apparent was how well it behaved at this track’s signature section, the Infineon esses, an absolute blast, again this dual spring suspension set-up has exceeded all my expectations.

One would think that with 550# front main springs and mere 28 mm rear torsion bars, the car would push like a pig, but NOT so!!!! The esses section is a great place to evaluate the car’s turn-in response as one modulates the throttle, and the hairpin turn at the end of the back straight a great place to evaluate the degree of inherent understeer.

Braking Zone. Go up to 120+ mph on the back straight on the approach to Turn #11 (the hairpin) and stomp on the brakes. The brakes are much easier to modulate over the undulating payment. Last year with the 350# springs there were some spots where the car used to bottom out under this heavy braking condition, the screech of tires, and flat spots soon followed as the tires searched for grip over the bumps.

This is a favorite passing zone for the really fast guys. This braking zone has to be respected the most, however, because of the proximity of outer a wall and the lack of run off area. However, lots of braking battles occur here and the only winners seem to be the flatbed tow trucks, they seem to conduct a lot of business at Turn 11.

I was also pleasantly surprised how well I could navigate through the downhill Turn #4. This turn has in the past given me problems, because with a downhill braking zone, and a greater than 90 degree off-camber right turn, the front outside spring would tend bottom out at turn-in and the car would tend to “push” no matter how much trail braking I dared to dial in - a tad too much trail braking and get ready for the spin!!! NOW, with the 550# main springs, what a difference, I like Turn 4. Easy as pie.

In summary, this suspension set up is perfect for a heavy street car, i.e. one that sees dual purpose Street/DE car.

The only thing I didn’t get to do on 3/21/09, was get a good clean lap in order to compare to last year’s 2:01 times. This was because the track was so crowded. NASA combined the Time Trialers (TT’s) with the HPDE-4 group into one session, with so many cars on track at the same time, there was just too much traffic, but on the upside, it gave me a good opportunity to practice passing. YMMV

Baseline: Koni Yellow struts, #350 x 10” front springs, and adjustable ride height kit. Not a good street/track compromise.

So the revised suspension.

Upgrade #2: dual spring package (2 ½” ID springs):

Hypercoil 8” x 550# main spring

Hypercoil Stacked Spring Divider,

Hypercoil 4” x 350# (tender spring)

PitstopUSA.com

2 550# Main Springs = HYPCO8-550 = $108

2 350# Tender Springs = HYPCO4-350= $108

2 Spring Dividers = HY-18DS100 = $56

Sub Total = $272

Upgrade #3 (Although not necessary, but for the more ambitious in the crowd, one can also convert to Koni Dual Adjustable Race Struts)

Summit Racing.com

Koni Race Yellows dual adjustable #8611-1259

2 Koni Race Struts = KON-86111259RACE = $620

Sub Total = $892.00

2.5” ID Dual Spring Combo (4” 350#Tender + 8” 550#Main)

The combined spring rate constant is calculated as follows: 1/Cf = 1/C1 + 1/C2

Initial combo rate = 214 lb/in.

In the picture below, you can see the adjustable height aluminum sleeve after being cut XX” (Do as I say, not as I do. Measure twice, cut only once.)

It is necessary to cut the threaded sleeve so that the spring separator (slider) can slide up and down above the spring perch on the smooth portion of the strut tube.

I highly recommend that suspension be mocked-up, wrap tape around the threaded collar to protect the threads (since one cannot use the spring slider at this point), assemble the dual spring combo and drive around for a week or two to let the suspension settle. Then take final measurements and cut the necessary threads off the aluminum threaded collar.

Depicted in the middle. Hypercoil spring Divider/slider HY-18DS100.

All the parts needed:

The assembled package - at full droop. The scratches seen is where the plastic slider is rubbing off the black painted tube.

Coming Soon, in a few days….

Section III. How to Design your own Dual Spring Rate Coilover suspension

(all measurements, specs, formulas, and estimates) - See post #24.

Section IV, "Lowering the car to improve cornering potential” - See post #35

Section V. Converting Single Adjustable Koni Yellows to Dual Adjustable (Bump and Rebound) Race Koni’s - see post #37

This has been a really fun project.

Last edited by Trucho-951; 04-13-2009 at 08:01 PM.

#2

hey trucho -

interesting......... I had thought about playing with this a bit for the especially rough tracks where a lighter tender spring might smooth out some of the surface instead of jarring the car offline

I am curious how high your ride height must be with 12" worth of spring? 8" main + 4" tender + divider - must be stock height?

you planning to play with any shorter springs to get ride height down?

interesting......... I had thought about playing with this a bit for the especially rough tracks where a lighter tender spring might smooth out some of the surface instead of jarring the car offline

I am curious how high your ride height must be with 12" worth of spring? 8" main + 4" tender + divider - must be stock height?

you planning to play with any shorter springs to get ride height down?

#3

Nordschleife Master

Perhaps you could help me figure out what to do with the rear end on my 951. I have a feeling I get too much roll and its going to resulting in rubbing the 295s. It feels less stiff than my old na but the potholes are KILLER, even with stock phone dials.

#4

Pro

Thread Starter

Join Date: Jun 2005

Location: Napa Valley, CA

Posts: 589

Likes: 0

Received 0 Likes

on

0 Posts

correctamundo!!! stock height, but waint untill my Section IV, where I explore lowering the car....

#5

Pro

Thread Starter

Join Date: Jun 2005

Location: Napa Valley, CA

Posts: 589

Likes: 0

Received 0 Likes

on

0 Posts

#6

Burning Brakes

Join Date: Oct 2007

Location: Blacksburg, VA

Posts: 891

Likes: 0

Received 0 Likes

on

0 Posts

I wonder if this could be done with the bilstein escorts as well... I have 250# springs on there right now and on some roads it can get a little rough and jarring. Ideally I'd like to go with a heavier spring and still have street use out of the car and this could very well be the solution!

#7

Rennlist Member

Interesting thread, I remember your original post on the subject and look forward to part III, IV and V.

Hope they come sooner than later as i'm planning a suspension upgrade in the coming months.

Hope they come sooner than later as i'm planning a suspension upgrade in the coming months.

Trending Topics

#8

Burning Brakes

can you mount the tender spring on top and then not have to deal with cutting the threaded body?

very interesting thread. i usually tend to hate progressive set ups (especially on a car with limited suspension travel) but your details makes me want to give this a try. have you tried this with a lowered ride height yet? you may run out of travel.

very interesting thread. i usually tend to hate progressive set ups (especially on a car with limited suspension travel) but your details makes me want to give this a try. have you tried this with a lowered ride height yet? you may run out of travel.

#10

Pro

Thread Starter

Join Date: Jun 2005

Location: Napa Valley, CA

Posts: 589

Likes: 0

Received 0 Likes

on

0 Posts

But I suppose if I hadn't cut the skirt off the original spring slider, it might work. I also don't like the idea of the Koni punching through the slider at high speed. Statistics and probability tell me it's not always going to be a pretty picture. But as the sliders are now short, I much rather have them at the bottom, where they are nice and safe.

Ah... I'll attemp to answer that in Section IV.

#11

Burning Brakes

keep up the good work. i love this thread! i am so interested in suspension design and no one ever, ever lists any helpful DETAILS. they only say a bunch of useless crap which is near indecipherable. it's all about the details, specifics, grit, low down dirty info. let this thread be a lesson to others: this is how you discus info.

ok, rant over.

what length spring is called for when using a single spring? it seems like if the total is the same as a single spring then things would work as they should as far as lowering and travel.

also, is there a distinct feel to when you run out of travel on the helper and the main spring comes into action? is it seamless? are there any issues with this transition? with such a lrge difference between the 2 spring rates, it would seem like definite step but i don't think you expressed anything like that.

hmmm, the choices are very interesting since one can choose similar rates or more drastic.

thanks & keep it coming!

ok, rant over.

what length spring is called for when using a single spring? it seems like if the total is the same as a single spring then things would work as they should as far as lowering and travel.

also, is there a distinct feel to when you run out of travel on the helper and the main spring comes into action? is it seamless? are there any issues with this transition? with such a lrge difference between the 2 spring rates, it would seem like definite step but i don't think you expressed anything like that.

hmmm, the choices are very interesting since one can choose similar rates or more drastic.

thanks & keep it coming!

#13

Addict

Lifetime Rennlist

Member

Lifetime Rennlist

Member

I wonder if this could be done with the bilstein escorts as well... I have 250# springs on there right now and on some roads it can get a little rough and jarring. Ideally I'd like to go with a heavier spring and still have street use out of the car and this could very well be the solution!

#14

Rennlist Member

I was doing a little internet searching... found this: http://scienceworld.wolfram.com/phys...sinSeries.html

So, if I take a stab at the math, I first must know a few things - specifically the weight at each front corner, and my motion ratio. (I'm just thinking out loud here...)

Front corner sprung weight: 750 lbs

Front motion ratio: .91

Trucho's spring rates: 350 lb/in tender; 550 lb/in main

Using the 2nd formula on that link, before max compression of the tender, the effective spring rate (of the 2 springs in series) is 213 lbs/in

The wheel rate (motion ratio squared times spring rate) is 177 lbs/in

The front suspension frequency is about 91 cycles per minute with the 2 springs working together

After full compression of the tender, the only spring rate is the 550 lb/in one - giving a wheel rate of 455 lbs/in and a frequency of 146 CPM

I wonder how the car would perform if these 2 suspension frequency numbers were brought a little closer together. Instead of a 55 CPM spread, how about a 20 or 30 or 40 CPM difference?

Maybe I'll have to do some experimenting, too! (of course I have the Bilsteins, so I cannot easily adjust the compression/rebound)

So, if I take a stab at the math, I first must know a few things - specifically the weight at each front corner, and my motion ratio. (I'm just thinking out loud here...)

Front corner sprung weight: 750 lbs

Front motion ratio: .91

Trucho's spring rates: 350 lb/in tender; 550 lb/in main

Using the 2nd formula on that link, before max compression of the tender, the effective spring rate (of the 2 springs in series) is 213 lbs/in

The wheel rate (motion ratio squared times spring rate) is 177 lbs/in

The front suspension frequency is about 91 cycles per minute with the 2 springs working together

After full compression of the tender, the only spring rate is the 550 lb/in one - giving a wheel rate of 455 lbs/in and a frequency of 146 CPM

I wonder how the car would perform if these 2 suspension frequency numbers were brought a little closer together. Instead of a 55 CPM spread, how about a 20 or 30 or 40 CPM difference?

Maybe I'll have to do some experimenting, too! (of course I have the Bilsteins, so I cannot easily adjust the compression/rebound)

#15

Pro

Thread Starter

Join Date: Jun 2005

Location: Napa Valley, CA

Posts: 589

Likes: 0

Received 0 Likes

on

0 Posts

I wonder if this could be done with the bilstein escorts as well... I have 250# springs on there right now and on some roads it can get a little rough and jarring. Ideally I'd like to go with a heavier spring and still have street use out of the car and this could very well be the solution!

As I mentioned in my original post, one of the major factors in having a comfortable street ride is being able to adjust your damping rates down to the softest settings. Perhaps you could give Bilstein USA a call and ask them to convert your Escort Cup struts to adjustables ala PSS9 or PSS10 style. There is NO technical reason why they would not be able to do it, however, I suspect that $$$ might be an issue here. Bilstein USA @ 1-858-386-5900. or http://www.bilstein.com/contact.php

Once you have adjustable struts, then you can come back and play with us…

also, is there a distinct feel to when you run out of travel on the helper and the main spring comes into action? is it seamless? are there any issues with this transition? with such a lrge difference between the 2 spring rates, it would seem like definite step but i don't think you expressed anything like that.

hmmm, the choices are very interesting since one can choose similar rates or more drastic.

thanks & keep it coming!

hmmm, the choices are very interesting since one can choose similar rates or more drastic.

thanks & keep it coming!

and yes, the transition is seamless.

I appreciate the enthusiasm, however, I really hope not to disappoint anyone here, as there were no 2nd Order Differential equations solved, nor was there any need for complex integration.

No, what I am attempting to do here is summarize stuff that is already available all over the internet, and present it in a simple cookie cutter, easy to follow approach. This is my little grain in the sand contribution in trying to help inch along our 951 community as we try to keep up with other forums which are light years ahead of us.

Also, just as this suspension project went through a few prototype stages, I know also that as we discuss suspension theory here, we can improve the calculations a lot. As long as we try to keep it simple enough, so that everyone here can benefit.

Although the arithmetic straight forward, the number crunching can get tedious, so I would like to post a spreadsheet. I know how to post snap shots of it, but does anyone here know how to post the actual Excel spreadsheet?