No Start Problem

#226

Pro

Thread Starter

I have already done that previously. What can be gained from this test?

#227

Rennlist Member

The 9 pin plug was cleaned, etc and the engine was a no start. There is no spare DME. So is the problem fuel or ignition.

if the engine starts with one or both of the two tests, then there are probably 3 scenarios to pursue. The most expensive is to send the DME to ECUdoctors to test, $100 plus shipping back and forth.

#228

Going back about spraying fuel...

You can check end-to-end continuity on the red/blue by using a wire to extend your DMM lead, and measuring continuity between the red/blue at any one of the fuel injector connectors, and pin 18 or 35 at the DME connector. The wires here are red/yellow, as they change at the fuel pump relay. It should be essentially zero ohms.

It is also possible that your fuel pump relay is intermittent, and again I would urge you try a spare relay if you have one, or to jumper it with the three wire jumper per Clark's instructions and see what happens. The fuel pump relay powers the red/blue wire.

Note to self: start looking for a spare DME.

#229

BTW, I'm not sure you know this, but we are trying to help you with the easiest and least expensive path for proceeding, I'm sure at this point you are very frustrated. If it were my car, I'd have a piercing probe to an oscilloscope through the high and low side wires of an injector connector to help diagnose this. I don't get the feeling you have the tools and/or experience to do this, so we are going down an alternate methodology which uses simpler tools and techniques. I do hope your can appreciate the time we are taking to help you solve your car's issue. We absolutely want your car to run.

The following users liked this post:

harveyf (05-10-2022)

#230

Rennlist Member

Hi Acantor,

orig44 has made some excellent points to support his and my focus back to the fuel injection electrical harness wiring and testing continuity. When testing the continuity red/blue wire from pin 18 and then pin 35 back to the wiring harness pin at a fuel injector. On one pin of fuel injector connector, the ohm reading is infinite because that is the ground pin and the other is close to zero ohm, the 12v supply which comes from pin 18 or pin 35. I would also wiggle the harness and the 9 pin connectorin the engine bay to see if the resistance changes, indicating issues with the wiring. There is a splitting of the red/blue wiring into 4 wires, one for each fuel injector 12v supply. Maybe there is an issue with the joint connector. The joint connector is in the area if the rear of the camshaft tower. We all want you to fix this frustrating situation.

Tom

orig44 has made some excellent points to support his and my focus back to the fuel injection electrical harness wiring and testing continuity. When testing the continuity red/blue wire from pin 18 and then pin 35 back to the wiring harness pin at a fuel injector. On one pin of fuel injector connector, the ohm reading is infinite because that is the ground pin and the other is close to zero ohm, the 12v supply which comes from pin 18 or pin 35. I would also wiggle the harness and the 9 pin connectorin the engine bay to see if the resistance changes, indicating issues with the wiring. There is a splitting of the red/blue wiring into 4 wires, one for each fuel injector 12v supply. Maybe there is an issue with the joint connector. The joint connector is in the area if the rear of the camshaft tower. We all want you to fix this frustrating situation.

Tom

Last edited by T&T Racing; 05-10-2022 at 09:20 AM.

#231

Pro

Thread Starter

Hi Acantor,

orig44 has made some excellent points to support his and my focus back to the fuel injection electrical harness wiring and testing continuity. When testing the continuity red/blue wire from pin 18 and then pin 35 back to the wiring harness pin at a fuel injector. On one pin of fuel injector connector, the ohm reading is infinite because that is the ground pin and the other is close to zero ohm, the 12v supply which comes from pin 18 or pin 35. I would also wiggle the harness and the 9 pin connectorin the engine bay to see if the resistance changes, indicating issues with the wiring. There is a splitting of the red/blue wiring into 4 wires, one for each fuel injector 12v supply. Maybe there is an issue with the joint connector. The joint connector is in the area if the rear of the camshaft tower. We all want you to fix this frustrating situation.

Tom

orig44 has made some excellent points to support his and my focus back to the fuel injection electrical harness wiring and testing continuity. When testing the continuity red/blue wire from pin 18 and then pin 35 back to the wiring harness pin at a fuel injector. On one pin of fuel injector connector, the ohm reading is infinite because that is the ground pin and the other is close to zero ohm, the 12v supply which comes from pin 18 or pin 35. I would also wiggle the harness and the 9 pin connectorin the engine bay to see if the resistance changes, indicating issues with the wiring. There is a splitting of the red/blue wiring into 4 wires, one for each fuel injector 12v supply. Maybe there is an issue with the joint connector. The joint connector is in the area if the rear of the camshaft tower. We all want you to fix this frustrating situation.

Tom

I just fixed the Fluke meter so if there are any special tests that use a Fluke 87, I can do them. As for the continuity tests, you guys want me to check from the red/blue wire at the 9 pin and the power wire on each of the injectors, pin 18 on the DME (assuming to ground?), and pin 35 (also assuming to ground). Just trying to make sure I read that right.

I really appreciate all your guy's help. And if it will be more helpful, I can pic up an oscilloscope because I am sure that I will use it some other time down the road.

#232

Rennlist Member

It looks like the Fluke 87 can check Duty Cycle. This is basically a way to track an on/off voltage situation and tell what percent of the time the voltage is on. The interesting thing about this is that your injectors do exactly this. They turn on for a short time, then off, then on, etc. They pulse. That results in the clicking you hear when they are running. So it would be interesting to check the duty cycle on each injector. I don't know what a "good" number is but it will be low at idle, maybe 10 to 20%. More importanly they should all be about the same. When you are at wide open throttle, the duty cycle will approach 100%. The Fluke 87 also has a graph function which might be fun to play with, as it is really just another way of showing what is going on with the voltages. And you will be checking DC voltage. Hopefully you have a manual for the Fluke that will show you exactly how to set it up. On my Fluke, Duty Cycle is not intuitive

All: Beyond my knowledge but is there a way to check current flow at the injectors instead of voltage? This seems like it would be the most valid parameter to show that they are working?

You will have to back feed your probes into the two wires for each injector. At this point, you may just want to remove the rubber boots on the injectors so you can get at the wires close to the Amp Junior plug. BTW there are reports of issues with cars having strange operability issues as it seems the wires coming out of the Amp Junior plugs are not insulated and can short to each other. Another good reason to pull the boot and lay eyes on it.

The early cars like yours do not have an active idle control valve, like on the later cars. The idle control is a dumb device, I believe called the Idle Air Valve, that is open when you do a cold start and gradually closes over a few minutes, based purely on time. See this thread for a picture https://rennlist.com/forums/924-931-...che-944-a.html

It is buried under your manifold. It might be interesting to remove its power feed (another Amp Junior connector) but more interesting would be to look through it and see if it is open to pass air when it is cold. If it has failed shut that would confuse the idle performance of the engine. But it is only for starts in cold weather so I don't think it is a primary culpret.

It's kind of a meat axe experiment but you might want to hack your throttle cable to hold the throttle butterfly valve open a small amount when you try to start the car. Equivalent of holding the pedal down but if it is just cracked open and the car starts that will tell us something. Also, I think we have gone over this but you should hear a small click when you crack open the throttle. This is the microswitch on the throttle body that tells the ECU that the throttle is fully closed. As usual, proof positive is to see it go from zero resistance to infinate back at the ECU plug as you depress the throttle.

All: Beyond my knowledge but is there a way to check current flow at the injectors instead of voltage? This seems like it would be the most valid parameter to show that they are working?

You will have to back feed your probes into the two wires for each injector. At this point, you may just want to remove the rubber boots on the injectors so you can get at the wires close to the Amp Junior plug. BTW there are reports of issues with cars having strange operability issues as it seems the wires coming out of the Amp Junior plugs are not insulated and can short to each other. Another good reason to pull the boot and lay eyes on it.

The early cars like yours do not have an active idle control valve, like on the later cars. The idle control is a dumb device, I believe called the Idle Air Valve, that is open when you do a cold start and gradually closes over a few minutes, based purely on time. See this thread for a picture https://rennlist.com/forums/924-931-...che-944-a.html

It is buried under your manifold. It might be interesting to remove its power feed (another Amp Junior connector) but more interesting would be to look through it and see if it is open to pass air when it is cold. If it has failed shut that would confuse the idle performance of the engine. But it is only for starts in cold weather so I don't think it is a primary culpret.

It's kind of a meat axe experiment but you might want to hack your throttle cable to hold the throttle butterfly valve open a small amount when you try to start the car. Equivalent of holding the pedal down but if it is just cracked open and the car starts that will tell us something. Also, I think we have gone over this but you should hear a small click when you crack open the throttle. This is the microswitch on the throttle body that tells the ECU that the throttle is fully closed. As usual, proof positive is to see it go from zero resistance to infinate back at the ECU plug as you depress the throttle.

#233

Pro

Thread Starter

I have tested the TPS and it is fine. I do still have the manual for the fluke so I will give that a look. For duty cycle, would I test that while it is connected to the injectors or with them unplugged and the engine cranking?

Ok so we are up to continuity tests between the red/blue wire on the 9 pin to the injectors, DME pins 18 and 35 to ground (pin 19 as ground), duty cycle of injectors, and possibly unplugging the air valve sensor to see what happens.

What about the idle air control valve by the air box? Could that be of any suspicion?

Ok so we are up to continuity tests between the red/blue wire on the 9 pin to the injectors, DME pins 18 and 35 to ground (pin 19 as ground), duty cycle of injectors, and possibly unplugging the air valve sensor to see what happens.

What about the idle air control valve by the air box? Could that be of any suspicion?

#235

Rennlist Member

I have tested the TPS and it is fine. I do still have the manual for the fluke so I will give that a look. For duty cycle, would I test that while it is connected to the injectors or with them unplugged and the engine cranking?

Ok so we are up to continuity tests between the red/blue wire on the 9 pin to the injectors, DME pins 18 and 35 to ground (pin 19 as ground), duty cycle of injectors, and possibly unplugging the air valve sensor to see what happens.

What about the idle air control valve by the air box? Could that be of any suspicion?

Ok so we are up to continuity tests between the red/blue wire on the 9 pin to the injectors, DME pins 18 and 35 to ground (pin 19 as ground), duty cycle of injectors, and possibly unplugging the air valve sensor to see what happens.

What about the idle air control valve by the air box? Could that be of any suspicion?

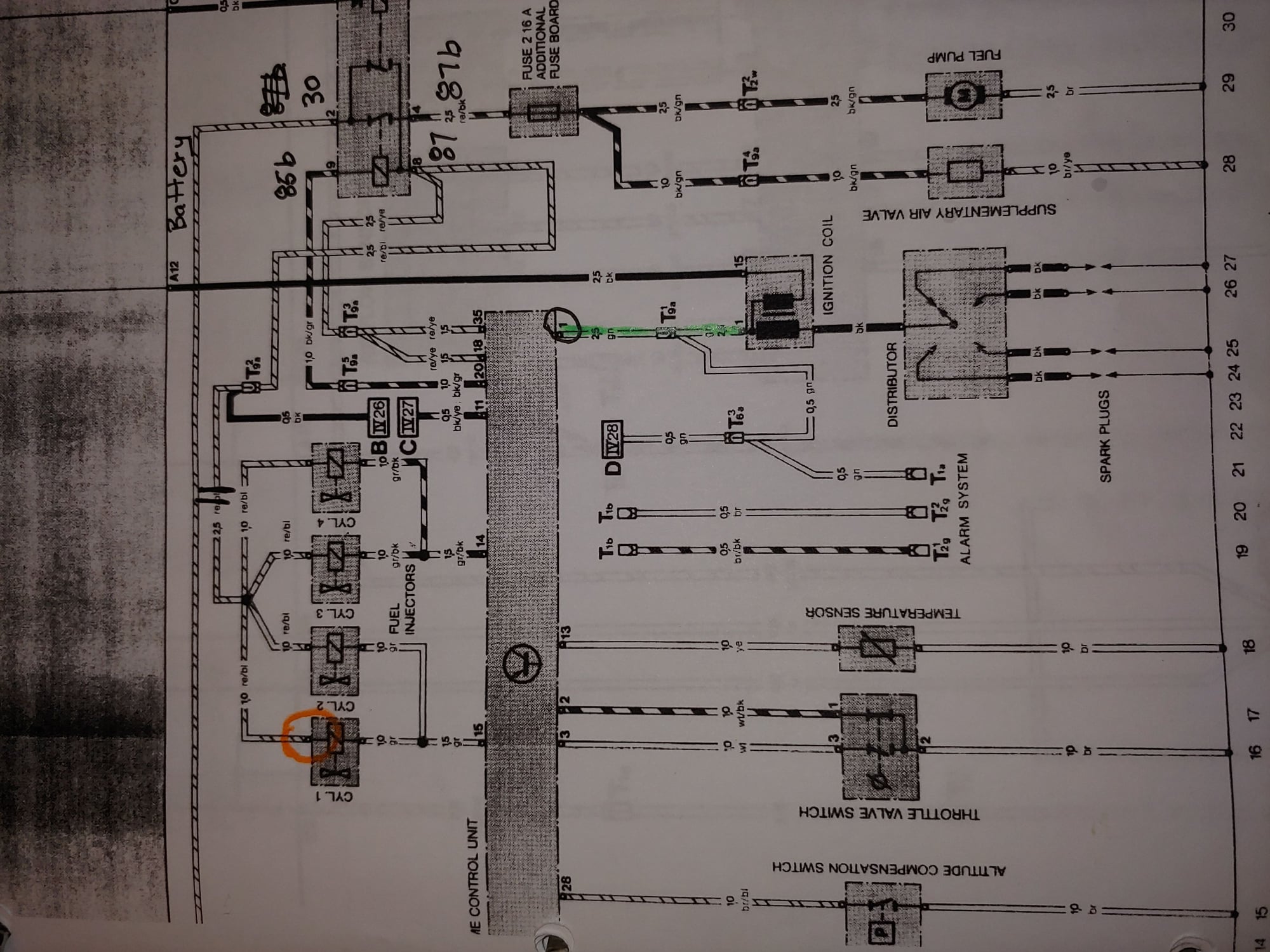

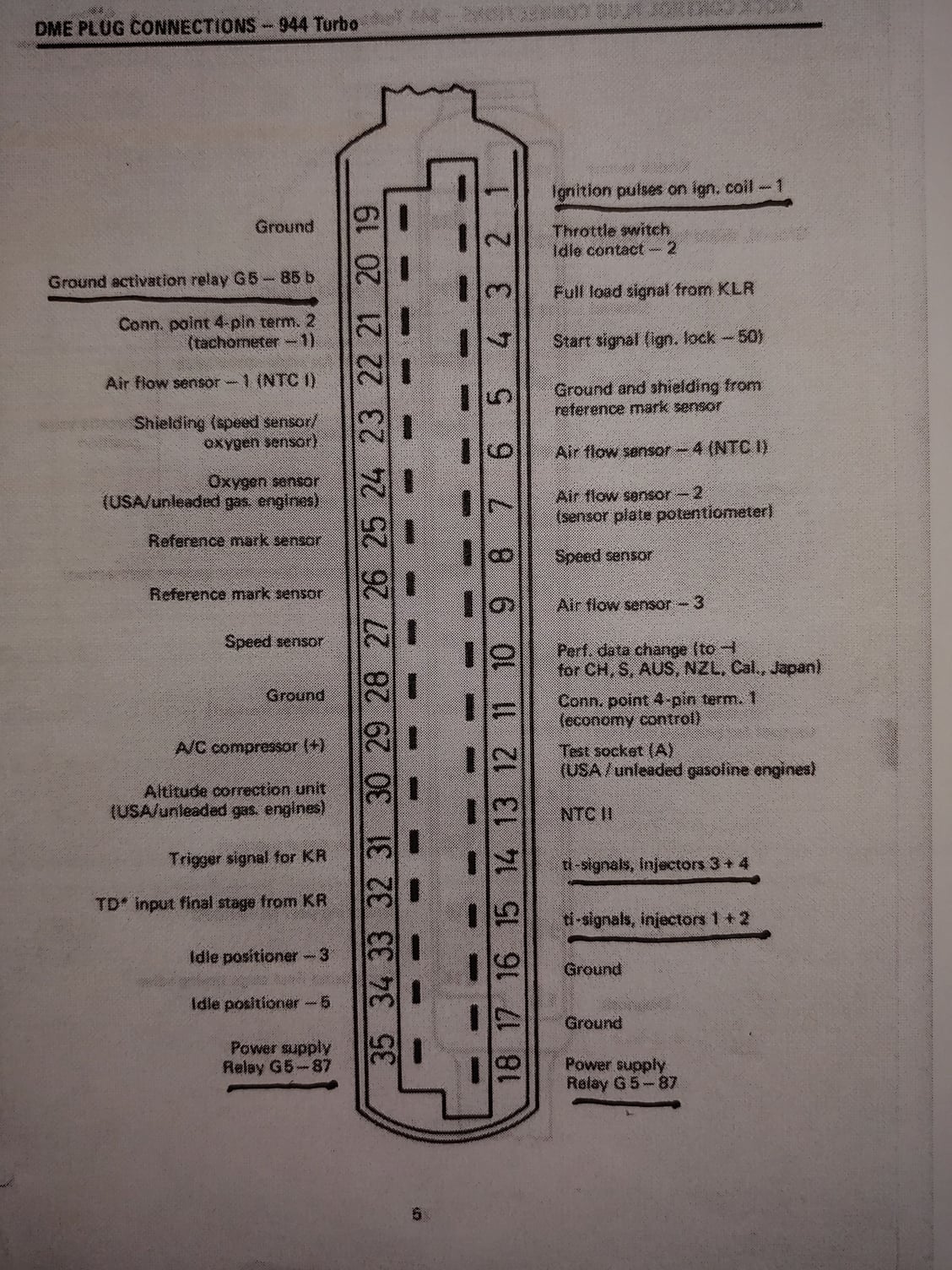

1. Make up a jumper wire (long length wire and make 16 or 18 guage wire that can be inserted into the DME plug #18 (see attached DME key. Run the wire from the drivers through the door opening into the engine compartment by the brake booster. Connect one lead of the Fluke to the wire. Plug the other end of the wire into pin #18

2. Refer to the wiring diagram below. Disconnect the electrical plug to fuel injector #1 and insert the other lead of the Fluke into the pin circled in orange. The best is to insert the probe into one pin. and then the other pin. If the reading is open circuit, then it is the green wire for the ground circuit. If thee reading shows continuity, then it is the red/blue wire 12v supply. Record the resistance.

3. Repeat the step 2 for fuel injectors #2, #3, #4.

4. Then switch the jumper wire on the DME plug to #35

5. Repeat steps 2 and 3.

6. You can try wiggling the fuel injector harness to see if the resistance changes

NOTE ON THE ELECTRICAL DRAWING: The 2.5mm red/blue wire has a connection node where the individual injector 12v supply wire terminates into that node. This could also be problem area

Wiring from DME to Fuel Injector Connector Plug

DME Plug Key Focus on Pin 18 and Pin 35

#236

Race Car

You have an intermittent problem.

Starting fluid is your friend.

You have to repeat the procedure from the beginning when the car is not starting.

It is not DME, coolant sensor, or any other spark related stuff and you can eliminate a whole lot of stuff if it runs on starting fluid.

For some reason I wasn't getting notifications on this thread thus the later response.

I repeat again. When the car is NOT starting, use starting fluid. Don't wiggle anything or do anything else.

You have to wait until the intermittent fault is at "no start" condition before you can diagnose anything.

Starting fluid is your friend.

You have to repeat the procedure from the beginning when the car is not starting.

It is not DME, coolant sensor, or any other spark related stuff and you can eliminate a whole lot of stuff if it runs on starting fluid.

For some reason I wasn't getting notifications on this thread thus the later response.

I repeat again. When the car is NOT starting, use starting fluid. Don't wiggle anything or do anything else.

You have to wait until the intermittent fault is at "no start" condition before you can diagnose anything.

#237

Rennlist Member

Just read and digested this. The battery is ground to the chassis. The starter motor is ground to the engine. If the fat ground wire from the chassis to the engine (bell housing) was disconnected, then if a start of engine was attempted, the one path if possible is thru the DME grounds and the other path is from the chassis thru torque tube, exhaust, motor mounts. etc. If one of the paths was the DME grounds, then part of the current flow to start the engine would generate substantial heat internally to the DME, maybe the grounding circuit that pulses the fuel injectors.

Acantor, when attempting to start the engine, what was observed?

Acantor, when attempting to start the engine, what was observed?

Last edited by T&T Racing; 05-11-2022 at 08:33 AM.

#238

Pro

Thread Starter

#239

Pro

Thread Starter

You have an intermittent problem.

Starting fluid is your friend.

You have to repeat the procedure from the beginning when the car is not starting.

It is not DME, coolant sensor, or any other spark related stuff and you can eliminate a whole lot of stuff if it runs on starting fluid.

For some reason I wasn't getting notifications on this thread thus the later response.

I repeat again. When the car is NOT starting, use starting fluid. Don't wiggle anything or do anything else.

You have to wait until the intermittent fault is at "no start" condition before you can diagnose anything.

Starting fluid is your friend.

You have to repeat the procedure from the beginning when the car is not starting.

It is not DME, coolant sensor, or any other spark related stuff and you can eliminate a whole lot of stuff if it runs on starting fluid.

For some reason I wasn't getting notifications on this thread thus the later response.

I repeat again. When the car is NOT starting, use starting fluid. Don't wiggle anything or do anything else.

You have to wait until the intermittent fault is at "no start" condition before you can diagnose anything.

#240

Race Car

If it has spark and starting fluid, it should start and run regardless of the temp sensor.

You have another problem.

And it appears to be intermittent.

Last edited by Legoland951; 05-10-2022 at 07:40 PM.