Drop Spindles for the 944/951/968

#1

Has anybody ever come up with a set of drop spindles?

This would be the ideal solution for dropping the car and keeping all the stock suspension and geometry and have no B-joint binding.

This would be the ideal solution for dropping the car and keeping all the stock suspension and geometry and have no B-joint binding.

#2

Rennlist Member

I think the best solution currently available is a longer ball joint pin in conjunction with a tie rod spacer (bump steer kit). For example, the rennbay geometry correction kit, racer's edge stuff, elephant racing, and my "high strung 44" arms with the monoball/adjustable pin length option.

But, you're right if a custom spindle were available with an extra couple inches between where the hub mounts and where the ball joint and tie rod connects, that would be a better way. Sounds really expensive though.

But, you're right if a custom spindle were available with an extra couple inches between where the hub mounts and where the ball joint and tie rod connects, that would be a better way. Sounds really expensive though.

#3

Less expensive than all the stuff you just posted. Do your arms offer a drop pin? I see the pic has replaceable B-joints. I am contemplating building a set that allows for 0 drop and a selectable 1" or 1.5" drop and all the suspension parts remain untouched.

#4

Rennlist Member

There are two versions of ball joints available on the high strung arms. Either the replaceable early 944style ball joint, or a monoball setup, that allows you to adjust pin length. I'll post some pics of that back here in a little bit.

#5

Rennlist Member

Here are some pics of the monoball version with adjustable pin length. This was actually the first one we made, and the design was modified slightly to give more brake rotor clearance. Sorry for the crappy cell phone pics.

#6

Rennlist Member

Keep us posted on your build. I'm curious to see what you come up with for the drop spindles. I guess the "easy" way would be to cut the spindle in half and weld a spacers in there, but that sounds scary.

#7

Yeah celly pics are o.k. with at least 2 mpxls.

The monoball end wasn't neccessary for the Modded Rx7 arms I developed. All that is needed is to swap the adapter bracket from bottom to top with 2ea 12mm grade 8 bolts from the original RX7 design and you get exactly a 1" drop and can keep the replaceble ball joints with no rotor interference....

The spindles will be 1-off, because the caliper ears have to remain true to the spindle shaft relation. I also want to design them where NA, Turbo, and M030 option radial calipers can be interchanged. That would be a challenge.

The monoball end wasn't neccessary for the Modded Rx7 arms I developed. All that is needed is to swap the adapter bracket from bottom to top with 2ea 12mm grade 8 bolts from the original RX7 design and you get exactly a 1" drop and can keep the replaceble ball joints with no rotor interference....

The spindles will be 1-off, because the caliper ears have to remain true to the spindle shaft relation. I also want to design them where NA, Turbo, and M030 option radial calipers can be interchanged. That would be a challenge.

Trending Topics

#10

Rennlist Member

If I understand what you're saying, that doesn't correct the geometry. What is important for geometry correction is the location of the ball joint relative to the center line of the spindle, and you aren't changing that.

It's a nice looking arm, though. Amazing how similar the dimensions are to the Porsche arm (probably not a coincidence).

It's a nice looking arm, though. Amazing how similar the dimensions are to the Porsche arm (probably not a coincidence).

#11

Actually I used a CMM at the university where I work on the stock 944 control arm to copy the 944 arm geometry over to the RX7 arm/adapter/944 early ball joint. All the aftermarket arms I've seen don't take into consideration the B-joint caster offset that the Porsche alloy arms have in relation to the X-member pivot point.

I used the RX7 arm for the adaptation because it is Jap alloy and although 2 times as strong as the 944 ally arm weighs less. I tried welding an adapter to the 944 arm for the replaceable joints and had blow thru because the 944 arm is crap alloy and porous.

The main reason for making the conversion parts for the RX7 arm was to have the best of both worlds...tight control arm suspension and quiet ride at the same time....The RX7 arm has off-the -shelf Graphite impregnated Polyurethane. Best on the market and lasts forever. I rode in a 944 with hard joints and the road noise and vibration I didn't like.

I used the RX7 arm for the adaptation because it is Jap alloy and although 2 times as strong as the 944 ally arm weighs less. I tried welding an adapter to the 944 arm for the replaceable joints and had blow thru because the 944 arm is crap alloy and porous.

The main reason for making the conversion parts for the RX7 arm was to have the best of both worlds...tight control arm suspension and quiet ride at the same time....The RX7 arm has off-the -shelf Graphite impregnated Polyurethane. Best on the market and lasts forever. I rode in a 944 with hard joints and the road noise and vibration I didn't like.

Last edited by xschop; 12-06-2009 at 01:37 PM.

#13

Rennlist Member

The main reason for making the conversion parts for the RX7 arm was to have the best of both worlds...tight control arm suspension and quite ride at the same time....The RX7 arm has off-the -shelf Graphite impregnated Polyurethane. Best on the market and lasts forever. I rode in a 944 with hard joints and the road noise and vibration I didn't like.

#14

Oh yeah I almost forgot the other reason for the swap. Other than the weak design of the 944 alloy ball-joint pockets, the sway bar locations are also weak whenever you put on the beefy m030 sway bars or after market large diameter stuff....

I designed a bracket that lets you keep all the stock factory sway hardware. I just full threaded (m10x1.5) the 944 drop link and this even allows for some preload adjustment....

[IMG]http://i94.photobucket.com/albums/l96/xschop

/944ArmSwapDroplinks.jpg[/IMG]

Later if you want to stick on some truly sick sway bar that mounts above the control arm, just get a female M10x 1.5 Heim link and bolt it onto the RX7 bracket

*****Do you mean the offset between the forward and rear inner joints; the holes don't line up. I don't know how the aftermarket arms handle that, seems like they would break because they don't have as much compliance as the stock arms do. My arms use sperical joints at those attachments so that misalignment is not a concern.****

I was referring to the stock 944 B-joint location in relation to those 2 pivot points. If you string-line the X-member center out to the B-joints, you will see that their centers sit forward of the x-member pivot centers. (I have the exact dimension programmed in my CNC from the CMM measurements off the 944 arm)

Funny you also mentioned front and rear pivots, because the average 944 owner doesn't know there is a 7mm drop that has to be dealt with when ridding the caster bolt back there. I have 7mm x-member spacers to remedy that....

I designed a bracket that lets you keep all the stock factory sway hardware. I just full threaded (m10x1.5) the 944 drop link and this even allows for some preload adjustment....

[IMG]http://i94.photobucket.com/albums/l96/xschop

/944ArmSwapDroplinks.jpg[/IMG]

Later if you want to stick on some truly sick sway bar that mounts above the control arm, just get a female M10x 1.5 Heim link and bolt it onto the RX7 bracket

*****Do you mean the offset between the forward and rear inner joints; the holes don't line up. I don't know how the aftermarket arms handle that, seems like they would break because they don't have as much compliance as the stock arms do. My arms use sperical joints at those attachments so that misalignment is not a concern.****

I was referring to the stock 944 B-joint location in relation to those 2 pivot points. If you string-line the X-member center out to the B-joints, you will see that their centers sit forward of the x-member pivot centers. (I have the exact dimension programmed in my CNC from the CMM measurements off the 944 arm)

Funny you also mentioned front and rear pivots, because the average 944 owner doesn't know there is a 7mm drop that has to be dealt with when ridding the caster bolt back there. I have 7mm x-member spacers to remedy that....

Last edited by xschop; 12-06-2009 at 01:48 PM.

#15

Here's an older pic of a locating rod I machined to find the 7mm dimension when deleting the caster bolt. The CMM setup later confirmed it....

Back to the lecture....what is the most common drop distance on the 944?

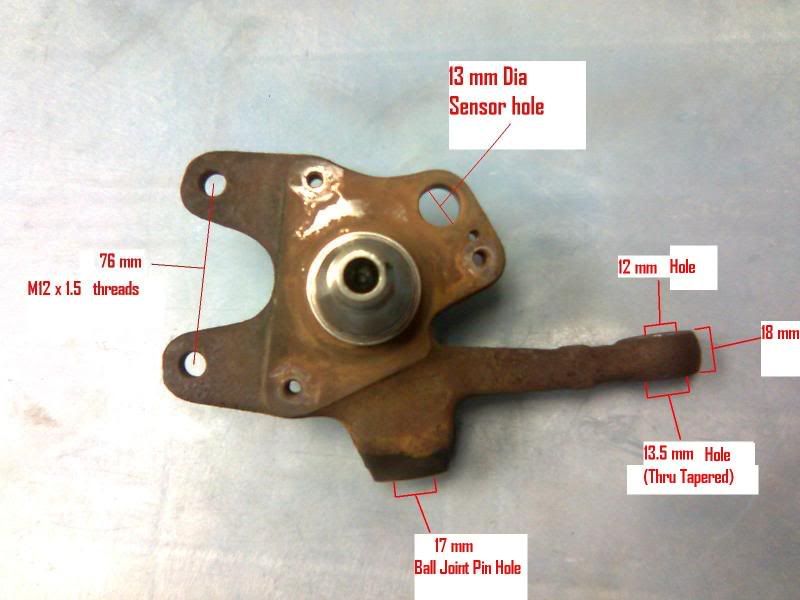

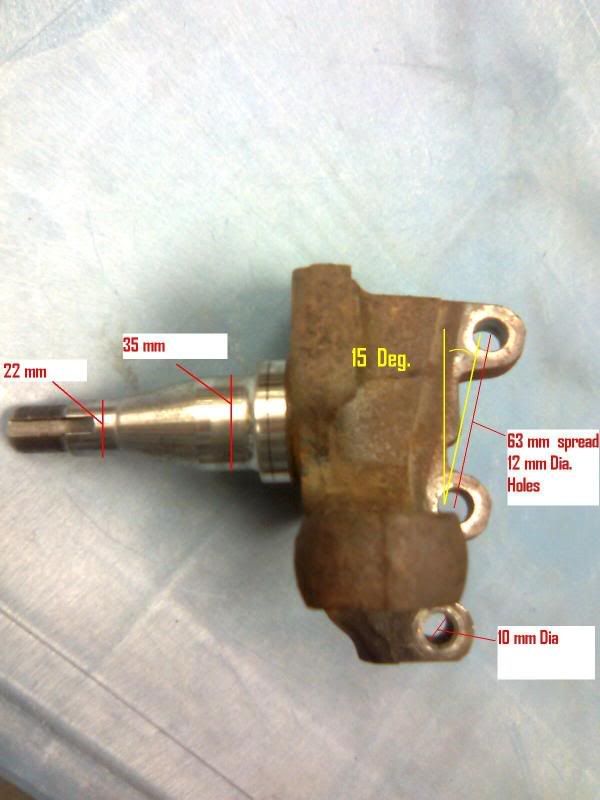

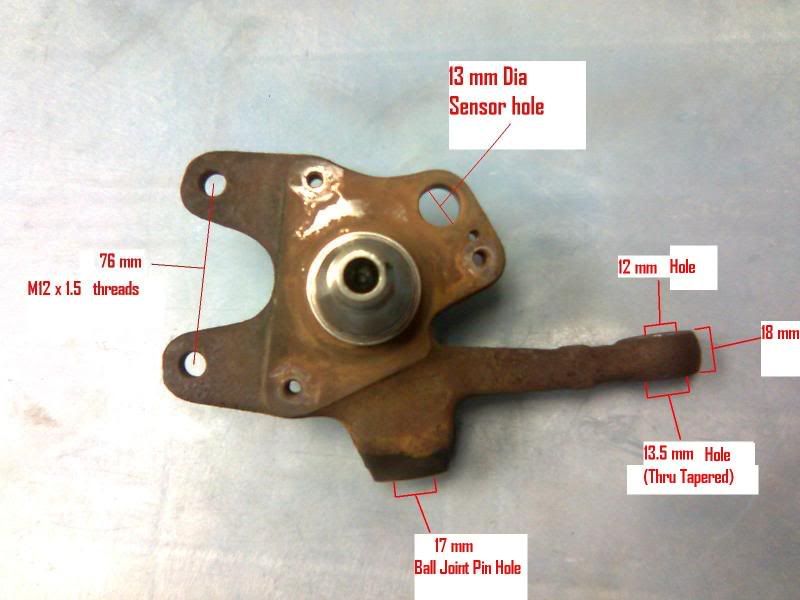

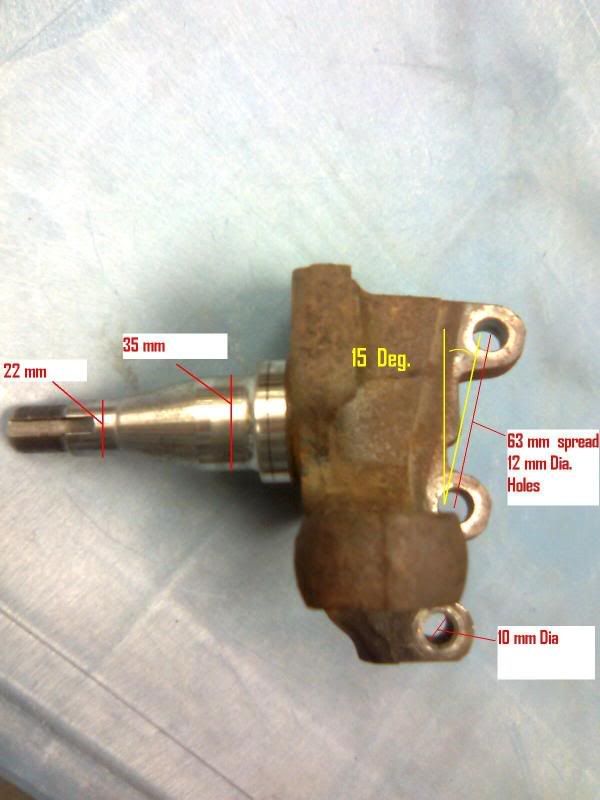

To properly do the drop, the shaft has to come up with the caliper ears, while the B-joint pin catch and tie-rod points along with the strut attachment point remain in their same relationship...

Back to the lecture....what is the most common drop distance on the 944?

To properly do the drop, the shaft has to come up with the caliper ears, while the B-joint pin catch and tie-rod points along with the strut attachment point remain in their same relationship...

Last edited by xschop; 12-06-2009 at 02:11 PM.