Oil pump quick question

#1

Track Day

Thread Starter

Did Porsche ever change anything about the oil pumps in the 928 engines between the generations? Also, did the oil delivery system change? My 2 engine blocks have different oil passage arrangements on the side where the oil cooler lines attach even though both blocks were from s4's supposedly.

Asking because ever since rebuilding my engine I've had funny oil pressure, even with brand new bearings and new Porsche original crankshaft the oil pressure is significantly lower than it ought to be. I've checked the oil galley block off pins in the heads, and replaced the oil thermostat but to no avail. More recently I've been hearing a small rattling noise coming from where the oil pump is on the front of the engine. When I was rebuilding the replacement block after thrust bearing failure killed the original one I had to machine the oil pump seat due to heavy scoring.

Going to rip the engine out to see more once my 2 post lift is free from my other project.

Id appreciate any insight on this.

Thanks,

Aleks

1990 Porsche 928 s4 5.0

Asking because ever since rebuilding my engine I've had funny oil pressure, even with brand new bearings and new Porsche original crankshaft the oil pressure is significantly lower than it ought to be. I've checked the oil galley block off pins in the heads, and replaced the oil thermostat but to no avail. More recently I've been hearing a small rattling noise coming from where the oil pump is on the front of the engine. When I was rebuilding the replacement block after thrust bearing failure killed the original one I had to machine the oil pump seat due to heavy scoring.

Going to rip the engine out to see more once my 2 post lift is free from my other project.

Id appreciate any insight on this.

Thanks,

Aleks

1990 Porsche 928 s4 5.0

#2

Team Owner

yes the oil pumps did change older pumps are different than newer pumps so it depends on the block you have as to what pump you use

The following users liked this post:

BETEPok (06-19-2021)

#3

Rennlist

Basic Site Sponsor

Basic Site Sponsor

Only early engines have different pumps and design changes...but I'm not certain of when the change occurred.

For certain, all 5 liter engines have the same design and use the same oil pump, so if both your engines were S4, that is not your problem.

For certain, all 5 liter engines have the same design and use the same oil pump, so if both your engines were S4, that is not your problem.

__________________

greg brown

714 879 9072

GregBBRD@aol.com

Semi-retired, as of Feb 1, 2023.

The days of free technical advice are over.

Free consultations will no longer be available.

Will still be in the shop, isolated and exclusively working on project cars, developmental work and products, engines and transmissions.

Have fun with your 928's people!

greg brown

714 879 9072

GregBBRD@aol.com

Semi-retired, as of Feb 1, 2023.

The days of free technical advice are over.

Free consultations will no longer be available.

Will still be in the shop, isolated and exclusively working on project cars, developmental work and products, engines and transmissions.

Have fun with your 928's people!

The following users liked this post:

BETEPok (06-19-2021)

#4

Track Day

Thread Starter

Okay noted, I will check the numbers on both of the blocks and both pumps to make sure it is what I say it is. Thanks.

Were the changes in the oil delivery system that would mean the blocks are different? If so, are there any diagrams floating around of both that I could reference?

Kindly,

Aleks

Were the changes in the oil delivery system that would mean the blocks are different? If so, are there any diagrams floating around of both that I could reference?

Kindly,

Aleks

#5

Rennlist Member

Have you checked the oil pressure with a mechanical pressure gauge or are you relying on the dash panel mounted gauge?

If the latter chances are you have a faulty sender or faulty wiring or both] in the engine harness.

If the latter chances are you have a faulty sender or faulty wiring or both] in the engine harness.

The following users liked this post:

BETEPok (06-19-2021)

#6

Track Day

Thread Starter

I haven't actually. I know I should have done that the moment I started having the issue. I will test it asap. Cheers

#7

Rennlist Member

Take a look at the wiring going from the engine into the 14 pin plug next to the hot post- it is a fair bet you will see cables with crumbling insulation or colours that are not recognisable due to the colour having been bleached out of them. The suspicious clue was your use of the word "funny" to describe the pressure as when they go the display can jump around a bit.

The sender on your model year is the three pin variant that has a wired earth as the third pin. Many of us have abandoned that and gone back to the earlier two pin variant that earths via the block. Also your model has a special three pin connector that is or was no longer available - maybe Roger [928srus.com] has them now?

Not sure if you are aware but as an FYI the sender is maxxed out at 5 barg and the gauge is then pegged at full span. The actual pressure may be higher and the system has a relief valve that pops at 8 barg. When cold the gauge should show 5 barg at idle speed and when hot 2 barg assuming you use a 20W50 grade oil.

The following users liked this post:

BETEPok (06-19-2021)

Trending Topics

#8

Chronic Tool Dropper

Lifetime Rennlist

Member

Lifetime Rennlist

Member

Know that if you had the cylinder heads reworked, there are some critical pieces in the oil system/passages that can be left out and will cause low oil pressure. I don't have the WSM pages in front of me; hopefully someone with that specific knowledge will jump in here and fill my memory gaps for us.

The following users liked this post:

BETEPok (06-19-2021)

#9

Track Day

Thread Starter

Aleks,

Take a look at the wiring going from the engine into the 14 pin plug next to the hot post- it is a fair bet you will see cables with crumbling insulation or colours that are not recognisable due to the colour having been bleached out of them. The suspicious clue was your use of the word "funny" to describe the pressure as when they go the display can jump around a bit.

The sender on your model year is the three pin variant that has a wired earth as the third pin. Many of us have abandoned that and gone back to the earlier two pin variant that earths via the block. Also your model has a special three pin connector that is or was no longer available - maybe Roger [928srus.com] has them now?

Not sure if you are aware but as an FYI the sender is maxxed out at 5 barg and the gauge is then pegged at full span. The actual pressure may be higher and the system has a relief valve that pops at 8 barg. When cold the gauge should show 5 barg at idle speed and when hot 2 barg assuming you use a 20W50 grade oil.

Take a look at the wiring going from the engine into the 14 pin plug next to the hot post- it is a fair bet you will see cables with crumbling insulation or colours that are not recognisable due to the colour having been bleached out of them. The suspicious clue was your use of the word "funny" to describe the pressure as when they go the display can jump around a bit.

The sender on your model year is the three pin variant that has a wired earth as the third pin. Many of us have abandoned that and gone back to the earlier two pin variant that earths via the block. Also your model has a special three pin connector that is or was no longer available - maybe Roger [928srus.com] has them now?

Not sure if you are aware but as an FYI the sender is maxxed out at 5 barg and the gauge is then pegged at full span. The actual pressure may be higher and the system has a relief valve that pops at 8 barg. When cold the gauge should show 5 barg at idle speed and when hot 2 barg assuming you use a 20W50 grade oil.

Hi,

Yeah, I'm using 20w50 oil right now. Its not acting erratically per se, its pegged at 5bar when I start it cold, then drops slowly. However, as its warming up the pressure (before the oil thermostat opens) drops to 3 bar. After driving a little bit it will drop below 1bar and cause a low oil pressure light to come on unless the engine is over 1000 rpm, which causes the pressure to increase slightly.

That is very low for an engine with brand new crank bearings and new crankshaft.

Most wiring on the car was replaced when a VEMS ecu was installed allowing for electronic ignition, but its still a really good shout to test it with a mechanical guage so I'll be doing that.

I know my ramblings about the oil passages looking different on the sides of the block are extremely vague, I will try to send comparison photos once I have the engine out, hopefully soon.

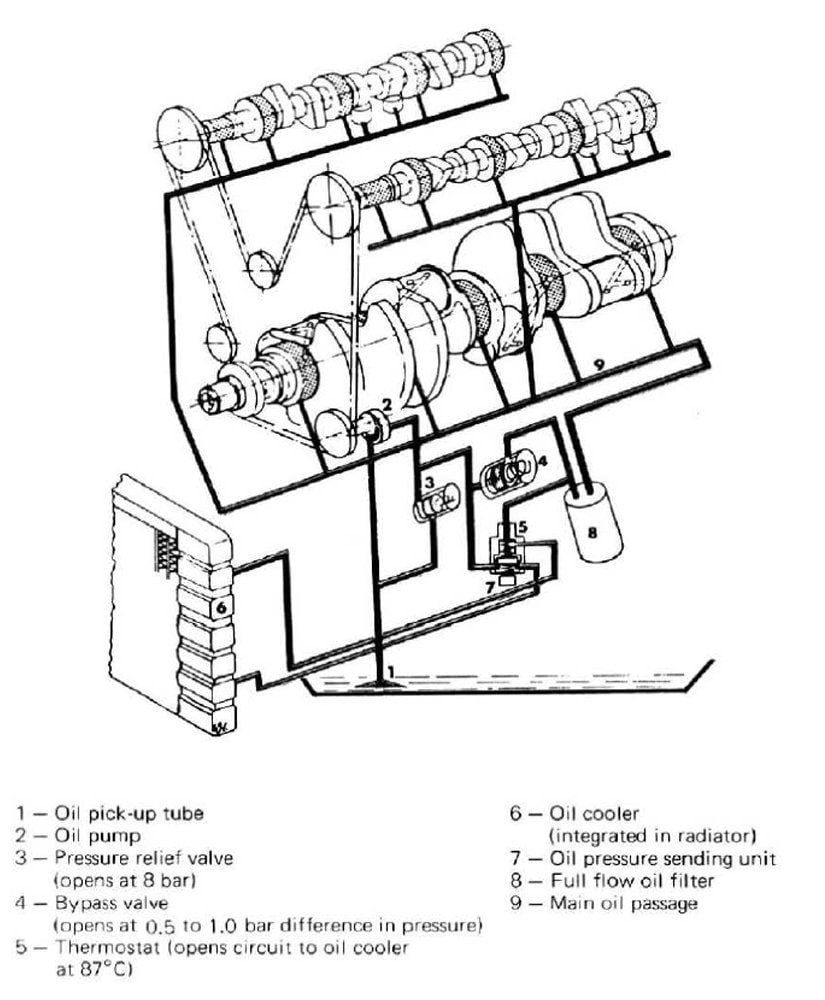

This is all I've been able to find

This is the only diagram I've been able to reference because its the only one I could find. I assume this is for an early car because of the SOHC? Assuming its of any use, the only thing I could think of contributing to low oil pressure would be a faulty or improperly installed bypass or pressure relief valves, since I've already replaced the thermostat. Of course a bad oil pump is not out of the question but I'll get to that in due time.

Thanks for taking the time to write your posts,

Aleks

#10

Track Day

Thread Starter

Know that if you had the cylinder heads reworked, there are some critical pieces in the oil system/passages that can be left out and will cause low oil pressure. I don't have the WSM pages in front of me; hopefully someone with that specific knowledge will jump in here and fill my memory gaps for us.

Could you elaborate? Has anyone had similar issues that ended up being head related in the end on the forums?

Best,

Aleks

#11

Rennlist

Basic Site Sponsor

Basic Site Sponsor

The difference in the blocks and the oil pumps is very minor...has to do with how the "excess" oil between the pump body and the front seal returns.

This, most like, will not be your problem.

There are oil "check *****" in both cylinder heads, which keep oil captive in the cylinder heads when the engine is not running.

Machinists/people that clean the heads can mess these check ***** up, in a never ending variety of ways.

The valves need to be removed, cleaned, and re-assembled with a new O-ring and set screw, especially after any engine failure or any cylinder head work.

Since I'm obviously not privy to what parts you used to build your new engine, it's tough to say much about potential problems.

For instance, if you reused the lifters from the thrust bearing failure engine, they will have been filled with the same "slushy" grey goop that your oil pan would have been filled with (They have a "ledge" inside that collects this "goop".)

Re-using the lifters will wash this "goop" into the new engine, ruining the bearings (and oil pump) very quickly.

This, most like, will not be your problem.

There are oil "check *****" in both cylinder heads, which keep oil captive in the cylinder heads when the engine is not running.

Machinists/people that clean the heads can mess these check ***** up, in a never ending variety of ways.

The valves need to be removed, cleaned, and re-assembled with a new O-ring and set screw, especially after any engine failure or any cylinder head work.

Since I'm obviously not privy to what parts you used to build your new engine, it's tough to say much about potential problems.

For instance, if you reused the lifters from the thrust bearing failure engine, they will have been filled with the same "slushy" grey goop that your oil pan would have been filled with (They have a "ledge" inside that collects this "goop".)

Re-using the lifters will wash this "goop" into the new engine, ruining the bearings (and oil pump) very quickly.

The following users liked this post:

BETEPok (06-19-2021)

#12

Track Day

Thread Starter

The difference in the blocks and the oil pumps is very minor...has to do with how the "excess" oil between the pump body and the front seal returns.

This, most like, will not be your problem.

There are oil "check *****" in both cylinder heads, which keep oil captive in the cylinder heads when the engine is not running.

Machinists/people that clean the heads can mess these check ***** up, in a never ending variety of ways.

The valves need to be removed, cleaned, and re-assembled with a new O-ring and set screw, especially after any engine failure or any cylinder head work.

Since I'm obviously not privy to what parts you used to build your new engine, it's tough to say much about potential problems.

For instance, if you reused the lifters from the thrust bearing failure engine, they will have been filled with the same "slushy" grey goop that your oil pan would have been filled with (They have a "ledge" inside that collects this "goop".)

Re-using the lifters will wash this "goop" into the new engine, ruining the bearings (and oil pump) very quickly.

This, most like, will not be your problem.

There are oil "check *****" in both cylinder heads, which keep oil captive in the cylinder heads when the engine is not running.

Machinists/people that clean the heads can mess these check ***** up, in a never ending variety of ways.

The valves need to be removed, cleaned, and re-assembled with a new O-ring and set screw, especially after any engine failure or any cylinder head work.

Since I'm obviously not privy to what parts you used to build your new engine, it's tough to say much about potential problems.

For instance, if you reused the lifters from the thrust bearing failure engine, they will have been filled with the same "slushy" grey goop that your oil pan would have been filled with (They have a "ledge" inside that collects this "goop".)

Re-using the lifters will wash this "goop" into the new engine, ruining the bearings (and oil pump) very quickly.

That's a pretty worrying thought. I had the heads rebuilt by a shop, I have no knowledge of HOW they did it. I don't know if they even opened up the lifters, so your suggestion may be a pretty plausible theory. If this ends up being the case and I find scoring on surfaces I am going to have to do a complete engine teardown. Not that I'm ill equipped for it, but this may end up being a much more expensive process than I thought.

This time however I'm equipped to do it all myself, as I have access to my own machine shop. Also my English has improved significantly, so I can use a lot of the resources that I couldn't 13 years ago.

We'll see how this goes.

Best,

Aleks

#13

Rennlist

Basic Site Sponsor

Basic Site Sponsor

Thanks for sticking with me for this long!

That's a pretty worrying thought. I had the heads rebuilt by a shop, I have no knowledge of HOW they did it. I don't know if they even opened up the lifters, so your suggestion may be a pretty plausible theory. If this ends up being the case and I find scoring on surfaces I am going to have to do a complete engine teardown. Not that I'm ill equipped for it, but this may end up being a much more expensive process than I thought.

This time however I'm equipped to do it all myself, as I have access to my own machine shop. Also my English has improved significantly, so I can use a lot of the resources that I couldn't 13 years ago.

We'll see how this goes.

Best,

Aleks

That's a pretty worrying thought. I had the heads rebuilt by a shop, I have no knowledge of HOW they did it. I don't know if they even opened up the lifters, so your suggestion may be a pretty plausible theory. If this ends up being the case and I find scoring on surfaces I am going to have to do a complete engine teardown. Not that I'm ill equipped for it, but this may end up being a much more expensive process than I thought.

This time however I'm equipped to do it all myself, as I have access to my own machine shop. Also my English has improved significantly, so I can use a lot of the resources that I couldn't 13 years ago.

We'll see how this goes.

Best,

Aleks

But try to understand....a full 60% of what we do is redoing someone else's attempt at repairing 928's.

There's a pretty clear list of pieces to replace, consider replacing, and pieces to clean, after an engine failure on page 17-11 of the Factory Workshop Manual.

If you refer to this page, it's pretty clear that the lifters must be replaced when there is a bearing failure....along with the oil filter, and chain tensioners.

Obviously very important, being right at the top of the list. Most of the other parts can be cleaned.

I was asking a question about parts used in an engine rebuild on a GTS (which had thrust bearing failure) that is currently up for sale on BaT, trying to get to the heart of what was replaced.

A client had asked me if this was a worthwhile car to bid on.

There were no replacement lifters listed in the parts list....and they are impossible to clean.

My question was flagged and removed for being non constructive....obviously because the seller did not want to address this huge issue.

If the original lifters were re-used, the buyer of this car is virtually guaranteed that the engine will be apart....again.

Needless to say, the answer to my client was: "Absolutely not"!

The following users liked this post:

BETEPok (06-19-2021)

#14

Track Day

Thread Starter

Hopefully I'm not offending you....people sometimes get offended by my questions and thoughts.

But try to understand....a full 60% of what we do is redoing someone else's attempt at repairing 928's.

There's a pretty clear list of pieces to replace, consider replacing, and pieces to clean, after an engine failure on page 17-11 of the Factory Workshop Manual.

If you refer to this page, it's pretty clear that the lifters must be replaced when there is a bearing failure....along with the oil filter, and chain tensioners.

Obviously very important, being right at the top of the list. Most of the other parts can be cleaned.

I was asking a question about parts used in an engine rebuild on a GTS (which had thrust bearing failure) that is currently up for sale on BaT, trying to get to the heart of what was replaced.

A client had asked me if this was a worthwhile car to bid on.

There were no replacement lifters listed in the parts list....and they are impossible to clean.

My question was flagged and removed for being non constructive....obviously because the seller did not want to address this huge issue.

If the original lifters were re-used, the buyer of this car is virtually guaranteed that the engine will be apart....again.

Needless to say, the answer to my client was: "Absolutely not"!

But try to understand....a full 60% of what we do is redoing someone else's attempt at repairing 928's.

There's a pretty clear list of pieces to replace, consider replacing, and pieces to clean, after an engine failure on page 17-11 of the Factory Workshop Manual.

If you refer to this page, it's pretty clear that the lifters must be replaced when there is a bearing failure....along with the oil filter, and chain tensioners.

Obviously very important, being right at the top of the list. Most of the other parts can be cleaned.

I was asking a question about parts used in an engine rebuild on a GTS (which had thrust bearing failure) that is currently up for sale on BaT, trying to get to the heart of what was replaced.

A client had asked me if this was a worthwhile car to bid on.

There were no replacement lifters listed in the parts list....and they are impossible to clean.

My question was flagged and removed for being non constructive....obviously because the seller did not want to address this huge issue.

If the original lifters were re-used, the buyer of this car is virtually guaranteed that the engine will be apart....again.

Needless to say, the answer to my client was: "Absolutely not"!

With what you've told me, it seems I'm in for a complete teardown.

I can't seem to be able to find the factory workshop manuals that you mentioned, I know I had them before - 13 years ago. Could you tell me where I can get them? It would be a huge help.

Thanks again,

Aleks

#15

Rennlist Member

Aleks,

There is no fundamental difference between the 16V lube system and the 32V lube system just that the latter obviously has more passageways in the heads. As GB and the WSM clearly state the lifters and tensioners must be replaced after bearing failure. Given the oil filter is a total system filter and in theory should catch any particulate matter of a size that can damage the engine I fail to understand why such recommendation should have been needed but it is clearly stated in black and white and the Porsche Engineers presumably [hopefully?] know what they are talking about.

As per the WSM the oil pressure must be a minimum of 5 barg at 4000 rpm with fully warmed up operating temperature. That the low pressure alarm triggered is worrisome given you were running 20W50 oil. This suggests to me that the gauge reading may well be realistic. I have seen 1 barg when the agents put Mobil 1 0W40 in the car without my knowledge/approval- I found out after a test drive and saw the low pressure on the gauge- told them to get it out of the motor immediately even though Porsche Middle East had confirmed to them it was OK for our motors! Shell Helix 20W50 was put in and i have used it ever since as it is the correct spec as per Porsche documentation.

Another thing to check is that the oil is circulating through the cooler correctly- i.e. the thermostat is opening correctly. You can check the temperature of the oil going into the cooler and out of it. You should be able to see a credible difference in temperature if the system is flowing- if it is not flowing then the temperature will be more or less the same both sides of the cooler. If it is not getting cooled correctly the viscosity will drop as will pressure at idle. I doubt this will be the case but...?

There is no fundamental difference between the 16V lube system and the 32V lube system just that the latter obviously has more passageways in the heads. As GB and the WSM clearly state the lifters and tensioners must be replaced after bearing failure. Given the oil filter is a total system filter and in theory should catch any particulate matter of a size that can damage the engine I fail to understand why such recommendation should have been needed but it is clearly stated in black and white and the Porsche Engineers presumably [hopefully?] know what they are talking about.

As per the WSM the oil pressure must be a minimum of 5 barg at 4000 rpm with fully warmed up operating temperature. That the low pressure alarm triggered is worrisome given you were running 20W50 oil. This suggests to me that the gauge reading may well be realistic. I have seen 1 barg when the agents put Mobil 1 0W40 in the car without my knowledge/approval- I found out after a test drive and saw the low pressure on the gauge- told them to get it out of the motor immediately even though Porsche Middle East had confirmed to them it was OK for our motors! Shell Helix 20W50 was put in and i have used it ever since as it is the correct spec as per Porsche documentation.

Another thing to check is that the oil is circulating through the cooler correctly- i.e. the thermostat is opening correctly. You can check the temperature of the oil going into the cooler and out of it. You should be able to see a credible difference in temperature if the system is flowing- if it is not flowing then the temperature will be more or less the same both sides of the cooler. If it is not getting cooled correctly the viscosity will drop as will pressure at idle. I doubt this will be the case but...?

The following users liked this post:

BETEPok (06-19-2021)