What’s going on with the 928 market?

#136

Drifting

That is nicely done. I will send this to the owner as he wants to do something similar.

odo claims 18k miles but it is a euro with MPH speedo. The car runs beautifully although we are having an issue getting spark plug wires for the twin dizzy. Any suggestions would be helpful. It was well maintained and looks worse than it is but sadly the car sat outside unloved for a the past few years once covid hit. It will be getting the full treatment. Starting with the engine. All refreshed hardware, vapor hone the intake and other bits. My good friend has been working on these since the 70's and is a top mechanic he loves the cars but he hates working on them.

The car runs beautifully although we are having an issue getting spark plug wires for the twin dizzy. Any suggestions would be helpful. It was well maintained and looks worse than it is but sadly the car sat outside unloved for a the past few years once covid hit. It will be getting the full treatment. Starting with the engine. All refreshed hardware, vapor hone the intake and other bits. My good friend has been working on these since the 70's and is a top mechanic he loves the cars but he hates working on them.

odo claims 18k miles but it is a euro with MPH speedo.

The car runs beautifully although we are having an issue getting spark plug wires for the twin dizzy. Any suggestions would be helpful. It was well maintained and looks worse than it is but sadly the car sat outside unloved for a the past few years once covid hit. It will be getting the full treatment. Starting with the engine. All refreshed hardware, vapor hone the intake and other bits. My good friend has been working on these since the 70's and is a top mechanic he loves the cars but he hates working on them.

The car runs beautifully although we are having an issue getting spark plug wires for the twin dizzy. Any suggestions would be helpful. It was well maintained and looks worse than it is but sadly the car sat outside unloved for a the past few years once covid hit. It will be getting the full treatment. Starting with the engine. All refreshed hardware, vapor hone the intake and other bits. My good friend has been working on these since the 70's and is a top mechanic he loves the cars but he hates working on them.Roger should have the correct Beru wires for this car. These yellow ones are beru connectors and I bought them from DEVEK!

edit: I almost forgot the most important part, after all the above is done get on a dyno with an exhaust reader and dial in the car using the MAF and AFPR to get right on 14.7 and slighty rich high up

Last edited by tv; 09-29-2022 at 11:57 AM.

#137

Rennlist Member

Not so sure what to say about that and I don't necessarily agree. Everyone can be an authority these days. Long before the RB sold I had a lot of people inquire about 928's and I saw the same interest as I did before the 964/964T's started skyrocketing in value. The Bad Boys turbo sold for far less than it should have brought but that is a long story. Although that sale was long after the values had already reached absurdity. Values increased due to interest and the realization there were so few in decent condition to choose from. Investors/buyers today are all about condition. So the OB's that sold for so much based on their theory would have sold for much less if it wasn't for the RB car? I am not so sure about that. It might have seen an increase in asking prices but IMO the cars that brought huge money would have irrespective of the RB sale. Condition drives the sales of all older Porsche's. People have learned it by buying bad 911's that finding the right condition car is key. No different than what Is saw unfold during the 80's grey market. I agree people need to educate themselves on which model is best to buy but prices are on the rise because the average person can afford to spend $45k and put another $15-20K into it but not as many can afford to spend multiple 6 figures to buy the best. So before these all start seeing increases like the 964 did people are trying to grab their dream Classic.

#138

Race Car

And this is where I think the 928 will have an advantage over other popular collector marques. The 928 community tends to be very self supporting and innovative when it comes to keeping our cars running. That ingenuity is what will fuel further development as the years go by. The other communities I follow most, old Land Cruisers and Triumphs, do not have a tenth of the support available. Granted those cars are more simply constructed, but even simple items which were available to buy new 20 years ago have vanished with no hope of coming back.

Last edited by GT6ixer; 09-29-2022 at 03:45 PM.

The following users liked this post:

928 GT R (09-29-2022)

#139

Rennlist Member

Simple. When there's a demand guess what happens, opportunity arises and new businesses are created. Look at NLA parts that Roger has commissioned to be built. I've supplied him with a few and intend to produce more parts and there are many more folks out there doing the same thing.

Agreed, but moldable parts of -a- surface quality are a far cry from interior and non-moldable parts. We dont have to argue what a -thin- market this is either, we both agree that it's a challenge.

Like Rogers cam gears...someone has to put forward 10s of 1000s of $ for a decade long payoff for real parts.

There are already 5spd trans parts that cant be made at any price slowly walking 5spd owners into an impossible corner.

Last edited by Speedtoys; 09-29-2022 at 03:57 PM.

#140

Race Car

Agreed, but moldable parts of -a- surface quality are a far cry from interior and non-moldable parts. We dont have to argue what a -thin- market this is either, we both agree that it's a challenge.

Like Rogers cam gears...someone has to put forward 10s of 1000s of $ for a decade long payoff for real parts.

Like Rogers cam gears...someone has to put forward 10s of 1000s of $ for a decade long payoff for real parts.

Now as far as the textiles go, that is an arena I am not familiar with. However there seems to be no end of upholstery shops that can do custom work and therefor likely to preproduce seats and carpets. Large plastic pieces like the headliner, dash, bumpers, and large sheet metal body panels will likely always be hard to come by and unlikely to be produced in small quantities at prices affordable to the lion's share of owners.

Last edited by GT6ixer; 09-29-2022 at 03:59 PM.

#141

Rennlist Member

Additive manufacturing will change this dramatically. For my day job in the aerospace sector we have access to manufacturing with metal additive processes that produce parts with the requisite strength that would be required for say a cam gear. The machines that can do this produce parts that currently would be cost prohibitive to sell to limited collector car market, but that is changing rapidly. Just 5 years ago the most affordable commercial metal printer was north of $1 million. Today it's $100K. In 5 mores years it will be $10K. At that point metal parts for limited runs (i.e. sub 1000 parts) will be an order of magnitude cheaper than trying to pay for investment casting or CNC machining.

Now as far as the textiles go, that is an arena I am not familiar with. However there seems to be no end of upholstery shops that can do custom work and therefor likely to preproduce seats and carpets. Large plastic pieces like the headliner, dash, bumpers, and large sheet metal body panels will likely always be hard to come by and unlikely to be produced in small quantities at prices affordable to the lion's share of owners.

Now as far as the textiles go, that is an arena I am not familiar with. However there seems to be no end of upholstery shops that can do custom work and therefor likely to preproduce seats and carpets. Large plastic pieces like the headliner, dash, bumpers, and large sheet metal body panels will likely always be hard to come by and unlikely to be produced in small quantities at prices affordable to the lion's share of owners.

I agree that the future is..untold, and I hope it works out...but in the next decade, I believe the gulf between savers and parts cars will widen, and the population of well sorted drivers (and better) will consolidate...and within that the "OE" restored population will be well rewarded, where 'personalized' modifications will start to take significant hits depending how far from "OE" the changes are..I'm riding that like, with no idea how it will work out.

The following users liked this post:

worf928 (09-30-2022)

#142

Race Car

I agree that the future is..untold, and I hope it works out...but in the next decade, I believe the gulf between savers and parts cars will widen, and the population of well sorted drivers (and better) will consolidate...and within that the "OE" restored population will be well rewarded, where 'personalized' modifications will start to take significant hits depending how far from "OE" the changes are..I'm riding that like, with no idea how it will work out.

#143

Rennlist Member

I agree. I would also say that the gulf would widen, albeit at a slower rate, even if a full suite of OE parts were available at reasonable prices. As far as OE vs Aftermarket I think that depends on the part. Maybe I'm completely wrong about this but I don't think "unseen" stuff like numbers matching cam gears are a "thing" in the collector car world?

Exactly..I dont have numbers matching cam gears..but who cares. I dont have numbers matching final drive ratio either..someone MIGHT care, but it was a change in the 'right direction', and added LSD.

I dont have numbers matching brake calipers either, but they are Porsche calipers...etc.

But at 160k (today) I wont ever be at 'that' level where someone will care that much. But, with everything now but the tub itself at 30K miles or less, it does stand apart from a simpler well maintained 160k mile car.

The following users liked this post:

GT6ixer (09-29-2022)

#144

Rennlist Member

Things that need to be done that affect performance > adjust throttle cable, check kickdown if auto, clean ALL grounds, clean and inspect 14 pin connector, purchase 2 AFPR's (euro's run lean), new injectors, Check or replace MAF, inspect harness, make sure nothing screwy was done to brains, new wires and plugs, new distributors, new dizzy toothed belt. check vacuum, all new fluids, and OPEN UP THE EXHAUST

Roger should have the correct Beru wires for this car. These yellow ones are beru connectors and I bought them from DEVEK!

edit: I almost forgot the most important part, after all the above is done get on a dyno with an exhaust reader and dial in the car using the MAF and AFPR to get right on 14.7 and slighty rich high up

Roger should have the correct Beru wires for this car. These yellow ones are beru connectors and I bought them from DEVEK!

edit: I almost forgot the most important part, after all the above is done get on a dyno with an exhaust reader and dial in the car using the MAF and AFPR to get right on 14.7 and slighty rich high up

Additive manufacturing will change this dramatically. For my day job in the aerospace sector we have access to manufacturing with metal additive processes that produce parts with the requisite strength that would be required for say a cam gear. The machines that can do this produce parts that currently would be cost prohibitive to sell to limited collector car market, but that is changing rapidly. Just 5 years ago the most affordable commercial metal printer was north of $1 million. Today it's $100K. In 5 mores years it will be $10K. At that point metal parts for limited runs (i.e. sub 1000 parts) will be an order of magnitude cheaper than trying to pay for investment casting or CNC machining.

He has been bugging me to find mag parts he can make in quantity which is more the issue but if you guys know of anything that we might be able to make in magnesium and need quality and strength let me know maybe i can help. I was about to embark on making 911 engine cases and parts for vintage race cars like 935's and 962's when my life took a sudden turn. Aluminum as well.

The following users liked this post:

928 GT R (09-29-2022)

#145

Rennlist Member

Happy Birthday, Dave! What a present you have for yourself. Is that an early 87 with the flip wing?

10 days ago I spoke to a guy here in SE Michigan about this car...he asked me what I thought it was worth. I'm guessing this is the same guy you bought it from.

Congrats on the purchase...good thing you have plenty of garage space

10 days ago I spoke to a guy here in SE Michigan about this car...he asked me what I thought it was worth. I'm guessing this is the same guy you bought it from.

Congrats on the purchase...good thing you have plenty of garage space

The following users liked this post:

928 GT R (09-29-2022)

#146

Race Car

I was looking over the new Guntherworks 993 at over $1M they are using a magnesium flat fan made by the additive manufacturing process. We started to dabble with it back in the early 2000's. Clearly it has come a long way. As a former 1st tier supplier of aluminum and magnesium castings for nearly every aerospace/defense contractor for half my life I see the benefits but is it as strong as a quality cast part? I would achieve between 38ksi to 46ksi Ultimate Tensile on average from cast magnesium although min specs required were far less and about the same or more from aluminum with a higher yield than the magnesium. I am not so sure these new process are able to achieve that but would be interested in hearing more.

One thing I didn't mention above, that is a big barrier to entry for any small business, like attempting to make metal parts for cars, is product liability. Insurance companies are no doubt behind the curve on new technologies and would likely view additive parts as high risk when compared to traditional manufacturing methods. Hopefully as more businesses enter the direct-to-consumer metal part market this will change and allow these types of businesses to trickle down to the niche of the collector car world.

#147

Rennlist Member

The big guys, Boeing and Airbus, are mostly printing in stainless steel and titanium alloys. Those processes and metallurgies can achieve UTs in the 100 to 150 ksi range. Aluminum additive process will be in the 60 ksi range with a yield strength being about half of that. I don't know of anyone printing in magnesium. It's pretty reactive stuff and I suspect there are a lot of challenges with laser sintering it in its powder form.

One thing I didn't mention above, that is a big barrier to entry for any small business, like attempting to make metal parts for cars, is product liability. Insurance companies are no doubt behind the curve on new technologies and would likely view additive parts as high risk when compared to traditional manufacturing methods. Hopefully as more businesses enter the direct-to-consumer metal part market this will change and allow these types of businesses to trickle down to the niche of the collector car world.

One thing I didn't mention above, that is a big barrier to entry for any small business, like attempting to make metal parts for cars, is product liability. Insurance companies are no doubt behind the curve on new technologies and would likely view additive parts as high risk when compared to traditional manufacturing methods. Hopefully as more businesses enter the direct-to-consumer metal part market this will change and allow these types of businesses to trickle down to the niche of the collector car world.

Funny that was my reaction as well and I tried several processes with mag that did not work due to its nature.

I have seen it in Titanium. Seems a better option than casting from what I gather. Very different applications though. I am fully aware of product liability especially for the rotating parts I made most were on The blackhawk/seahawk/SS/Chanock etc. I spent years making reproduction parts for vintage Ferrari and I even cast wheels for older F1 cars which is a huge risk factor. I used to trade my friend Joe Nastasi parts for vintage cars like his Typo 33/3 that won Mille Miglia beating Ferrari and Porsche and he would bring me barrels full of 512 engine cases that had cracks or damage. I turned them into cheap anodes. I sent the parts out for testing and I was appalled by what I found. Their metallurgy and tensile was below spec by a large margin. I doubt you will need more than what I was able to achieve for most applications but these new technologies are intriguing to me. Clearly it took a lot longer to get where the industry expected these processes to be by about 35 years or more.

Funny how Sikorsky told me I would be out of business by 1989 with composites and sintering technology. They were in quite a bind when the doors were closed. Supposedly they couldn't find another foundry to meet the criteria for 5 years. Another cast material that might have a good application for some car parts is almag35 a very uncommon alloy that has great potential but never quite caught on.

I tried to get them to open up the engine so I could see it up close but they wouldn't open it up. I am assuming it is operational but they had this prototype and Singer had their turbo exercise there as well. I just don't understand the need for these cars but I do appreciate the craftsmanship.

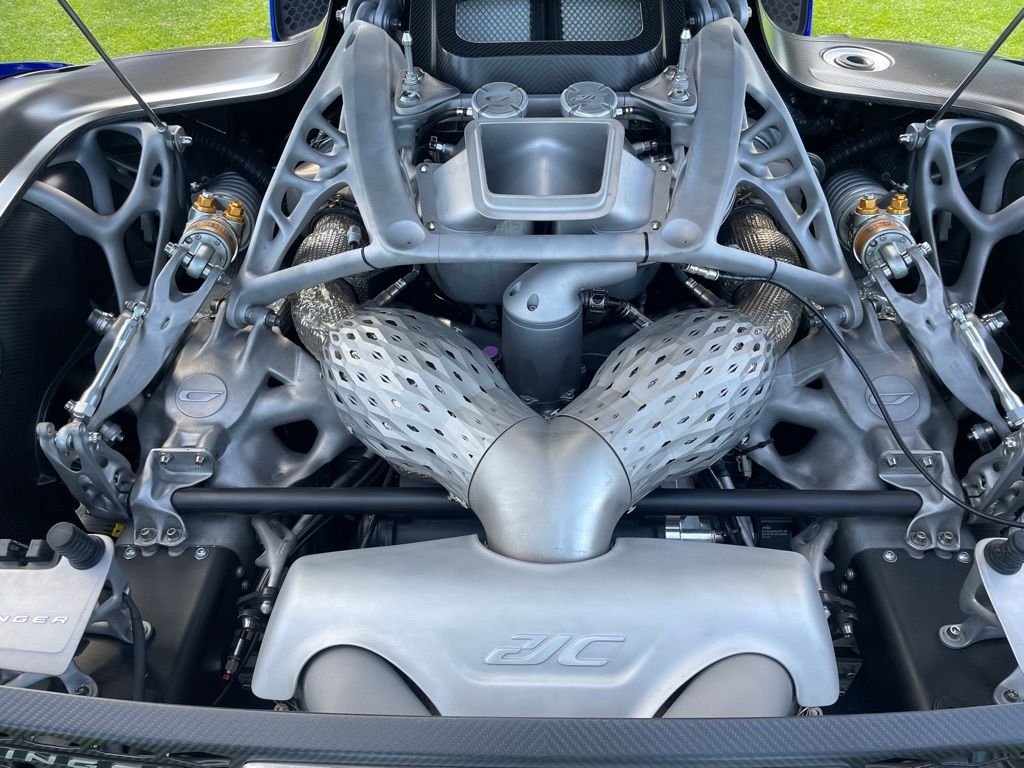

BTW off topic but some sintered Ti at its finest. I can appreciate the technology and effort to build this.

The following users liked this post:

Ghosteh (09-29-2022)

#149

Race Car

Czinger. I love what they are doing. What's most impressive is the stress software they are using to develop the organic looking suspension bits. Koenigsegg also is doing some real cool stuff with AM.

#150

Burning Brakes

This video doesn't exactly fit this thread, but parts of it made me smile (and identify with) the addictions that come with 928 ownership.

https://youtu.be/H5vgwBBspjc

https://youtu.be/H5vgwBBspjc

This thread is dangerously headed off topic, but it's entertaining!

Last edited by Ghosteh; 09-29-2022 at 10:32 PM.