Making your own Pilot Bearing puller

#1

Nordschleife Master

Thread Starter

Last weekend, Jon928se came over to my place and helped me with my first clutch removal.. well, I say "helped", but basically I was tool caddy in a "pass me the 9 iron please" type of role

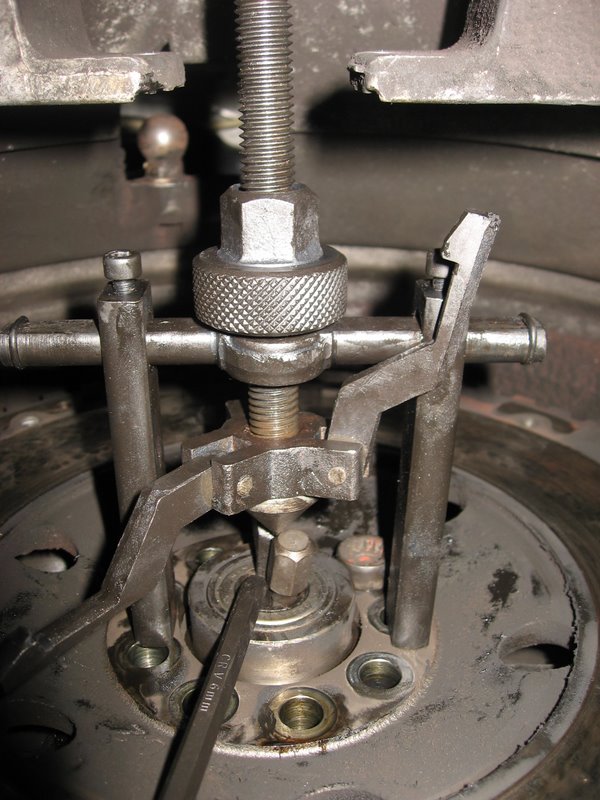

When it got to the Pilot bearing however, the Harbor Freight 1/2" puller just wasn't fitting right, so after a bit of creativity and trying different sizes, we came up with this.

Ingredients:

Put the nut onto the bolt, far enough that if can be tucked over the inner edge of the pilot bearing. Then wedge the 5mm hex key in there too.. you might have to turn the bolt a bit until there's space as the fit is close.

Then just tighten the bolt and it'll start pulling the bearing out

You may need to pause halfway, loosen the nut, and twist the hex key and bolt until the bolts on the opposite side - to pull the bearing out evenly.

So, forget the fancy Harbor Freight puller and behold..

Here's how it works in operation. You can see the 1/4" extension is just to stop the hex key from spinning as you tighten the bolt and the nut pushes on the key.

Here's the back-side after the bearing popped out, so you can see what goes on in there.

Thanks to Jon for the help.. it was hugely appreciated and I dropped off my flywheel for resurfacing this afternoon

When it got to the Pilot bearing however, the Harbor Freight 1/2" puller just wasn't fitting right, so after a bit of creativity and trying different sizes, we came up with this.

Ingredients:

- 1x M8 50mm bolt and nut

- 1x 5mm hex key

- 1x short 1/4" extension bar (anything that fits into a flywheel bolt hole will work)

Put the nut onto the bolt, far enough that if can be tucked over the inner edge of the pilot bearing. Then wedge the 5mm hex key in there too.. you might have to turn the bolt a bit until there's space as the fit is close.

Then just tighten the bolt and it'll start pulling the bearing out

You may need to pause halfway, loosen the nut, and twist the hex key and bolt until the bolts on the opposite side - to pull the bearing out evenly.

So, forget the fancy Harbor Freight puller and behold..

Here's how it works in operation. You can see the 1/4" extension is just to stop the hex key from spinning as you tighten the bolt and the nut pushes on the key.

Here's the back-side after the bearing popped out, so you can see what goes on in there.

Thanks to Jon for the help.. it was hugely appreciated and I dropped off my flywheel for resurfacing this afternoon

The following users liked this post:

dlknight (12-02-2023)

#3

Drifting

Hilton, you can persuade the Harbor Freight Pilot Bearing Puller to work. This is how I did it when Jon928se helped me with my clutch a few years ago. Jon was working on the Release Bearing at the time, which was probably why he didn't suggest the same solution this time.

#4

Nordschleife Master

Thread Starter

Hilton, you can persuade the Harbor Freight Pilot Bearing Puller to work. This is how I did it when Jon928se helped me with my clutch a few years ago. Jon was working on the Release Bearing at the time, which was probably why he didn't suggest the same solution this time.

Thats a lot tidier than this...

Still, an M8 bolt is definitely the cheapo alternative

#6

Team Owner

Some great ideas for the pilot bearing removal , i would add that things will go a bit easier if you use a torch to warm the rear of the crank up and then spray on some PB blaster prior to pilot removal,

A lot of the throw our bearing/pilot bearing failure can be attributed to water getting into the clutch. How does this happen? well if the you notice on the top of the bellhousing there is an opening for the release arm to attach to, so any good engine wash and a good bit of the water rinses right down the hole into the clutch/ pilot/thrust bearing and it starts to rust and in short time the bearings start going bad.

Remember on a 928 that when the engine is running the throw out bearing is running at engine speed, so this will seem to wear out faster and it does compared to other cars, but it will last longer if you dont let the engie get wet, used compressed air to remove dirt. ( some car clutch systems are made so the throw out bearing only spins when the clutch is used but 928 is different.)

A lot of the throw our bearing/pilot bearing failure can be attributed to water getting into the clutch. How does this happen? well if the you notice on the top of the bellhousing there is an opening for the release arm to attach to, so any good engine wash and a good bit of the water rinses right down the hole into the clutch/ pilot/thrust bearing and it starts to rust and in short time the bearings start going bad.

Remember on a 928 that when the engine is running the throw out bearing is running at engine speed, so this will seem to wear out faster and it does compared to other cars, but it will last longer if you dont let the engie get wet, used compressed air to remove dirt. ( some car clutch systems are made so the throw out bearing only spins when the clutch is used but 928 is different.)

Trending Topics

#8

Supercharged

Rennlist Member

Rennlist Member

Join Date: May 2002

Location: Back in Michigan - Full time!

Posts: 18,925

Likes: 0

Received 59 Likes

on

33 Posts

Nice bearing puller. I'll file this one away.

Huh? I know this debate has come up before, but when the clutch is engaged, the TT spins at the crank speed (whether in neutral or any gear), right?

If so, then the pilot bearing is not spinning (i.e. inner and outer portions are not spinning in relation to each other). The only time the pilot bearing spins is when the clutch pedal is depressed and the clutch is disengaged.

If so, then the pilot bearing is not spinning (i.e. inner and outer portions are not spinning in relation to each other). The only time the pilot bearing spins is when the clutch pedal is depressed and the clutch is disengaged.

#9

Drifting

But the release bearing always spins at engine speed.

#10

Rennlist Member

I never got the grease-pressure thing to work. Last time I did one on the 928, I took a plain flat washer and made it into a 'U' shape. Put a long bolt through the hole and slid the washer into the pilot bearing hole allowing the washer to open with the shoulders of the 'U' up against the bearing - think toggle bolt. Then put a large socket over the outside of the bearing, followed by another washer and turned a nut to pull the bearing right out. Total cost was the sacrificial washer. Worked like a charm and I'll use it next time.

#11

Archive Gatekeeper

Rennlist Member

Rennlist Member

If anyone wants to borrow a 2-prong puller that works nicely for the price of shipping back and forth, I'm done with mine for a few years:

#12

Burning Brakes

Join Date: Jan 2002

Location: Springfield, MO

Posts: 842

Likes: 0

Received 0 Likes

on

0 Posts

Here's my puller. It's more like a permanent tool though.

Write up: https://rennlist.com/forums/showthre...bearing+puller

Write up: https://rennlist.com/forums/showthre...bearing+puller

#13

Chronic Tool Dropper

Lifetime Rennlist

Member

Lifetime Rennlist

Member

Rob--

Just looking at the picture you posted, it looks like the center bolt is intended to go down through that lower block. and wedge itself in between the two fingers right about where the screwdriver is wedged. After the bolt has the fingers wedged and secure, then tighten the nut to actually extract the bearing.

Am I reading the pic wrong?

Just looking at the picture you posted, it looks like the center bolt is intended to go down through that lower block. and wedge itself in between the two fingers right about where the screwdriver is wedged. After the bolt has the fingers wedged and secure, then tighten the nut to actually extract the bearing.

Am I reading the pic wrong?

#14

Team Owner

Andrew, the Pilot bearing runs at the end of the crank and on the tip of the small input shaft, its there to help add a centing force to the shaft and provide a way to have the engine spin and the shaft stopped while the clutch pedal is pushed down. (So the drive force is stopped from continuing to the driveshaft)

That said The throw out bearing ( the one thats clamped to the rear side of the pressure plate) always spins at engine speed on a 928 regardless of the position of the clutch pedal, thats why the bearings dont seem to last as long as other cars throwout bearings do, plus the fact of water ingestion into the clutch via the top hole on the bell housing. My guess is that the water can also run down the aircleaner housing and drip into the hole as well .

UK Kidd has mentioned something about a rubber plug for the bell housing hole, I have never seen one , a picture might be good here UK???

That said The throw out bearing ( the one thats clamped to the rear side of the pressure plate) always spins at engine speed on a 928 regardless of the position of the clutch pedal, thats why the bearings dont seem to last as long as other cars throwout bearings do, plus the fact of water ingestion into the clutch via the top hole on the bell housing. My guess is that the water can also run down the aircleaner housing and drip into the hole as well .

UK Kidd has mentioned something about a rubber plug for the bell housing hole, I have never seen one , a picture might be good here UK???

#15

Archive Gatekeeper

Rennlist Member

Rennlist Member

Bob-

You're reading it exactly right. The problem is that the damn pilot bearing is in there so tight, even with the center bolt driven hard into the fingers (spreading them apart), as you tighen the nut, the fingers bend inwards and pull though the bearing. This is after a week or so of hitting the bearing with Kroil on a regular basis. The screwdriver is wedged in there to prevent the fingers from bending. Crude, but it worked.

You're reading it exactly right. The problem is that the damn pilot bearing is in there so tight, even with the center bolt driven hard into the fingers (spreading them apart), as you tighen the nut, the fingers bend inwards and pull though the bearing. This is after a week or so of hitting the bearing with Kroil on a regular basis. The screwdriver is wedged in there to prevent the fingers from bending. Crude, but it worked.

- that's a good solution.

- that's a good solution.