CIS leaning out

#1

Rennlist Member

Thread Starter

Well, knocking on wood worked for a couple years. But now I've got a problem.

With the mixture a-ok at idle, she is leaning way out under any load at all.

I have a A/F mixture gauge from Summit Racing and it says things are not good.

I've really richened it up at idle (12-13:1) and keep a light foot but under much of a load she jumps up to 15, 16, 17:1. Not good.

Seems to run just fine. Can't hear any detonation under load (not that I'm giving her any).

So out will come the pressure gauges this weekend to figure out what is up.

Think the control pressure is too high.

And maybe the vacuum connected to the WUR is not dropping control pressure with manifold vacuum drop.

Runs fine. Without the A/F gauge, I wouldn't have noticed, maybe until a broken ring land?

With the mixture a-ok at idle, she is leaning way out under any load at all.

I have a A/F mixture gauge from Summit Racing and it says things are not good.

I've really richened it up at idle (12-13:1) and keep a light foot but under much of a load she jumps up to 15, 16, 17:1. Not good.

Seems to run just fine. Can't hear any detonation under load (not that I'm giving her any).

So out will come the pressure gauges this weekend to figure out what is up.

Think the control pressure is too high.

And maybe the vacuum connected to the WUR is not dropping control pressure with manifold vacuum drop.

Runs fine. Without the A/F gauge, I wouldn't have noticed, maybe until a broken ring land?

#2

Racer

Having just ventured into the world of the WUR I would bet you that o-ring inside yours needs to be replaced. A rebuild costs about $280 (I can give you the info on where to send it, and sometimes they just swap them out) or a DIY kit about $100. It isn't hard to work on but you have to get the right o-ring, everything in that WUR exists to compress or relax that thing (it is the control pressure regulator!)

My control pressure would get so high my car wouldn't accelerate when warm! 58psi was what it would reach if I set the cold pressure to 30 psi. To get in the right range I had to set cold pressure to less than 1 bar....!!!

My control pressure would get so high my car wouldn't accelerate when warm! 58psi was what it would reach if I set the cold pressure to 30 psi. To get in the right range I had to set cold pressure to less than 1 bar....!!!

#3

Race Car

Well, avatar inidates you've been through it pretty well already!

Still many things could be culprit.

Sticking plunger in FD.

CHeck voltage at fuel pump.

I'm always thinking of the confounded union at the fuel feed to the FD, but looks like your system is probably well-refreshed.

I see why you're thinkin the vacuum enrichment circuit, but I wonder whether it is really intended to cover the enrichment margin for moderate throttle inputs to the extent that a faul would yield that kind of lean condition. I doubt it, I think it provides an extra little fuel dump at WOT for safety's sake-- but that is supposition on my part.

But back to baseline- so when you say it is ok at idle was that before, or after you richened it?

Still many things could be culprit.

Sticking plunger in FD.

CHeck voltage at fuel pump.

I'm always thinking of the confounded union at the fuel feed to the FD, but looks like your system is probably well-refreshed.

I see why you're thinkin the vacuum enrichment circuit, but I wonder whether it is really intended to cover the enrichment margin for moderate throttle inputs to the extent that a faul would yield that kind of lean condition. I doubt it, I think it provides an extra little fuel dump at WOT for safety's sake-- but that is supposition on my part.

But back to baseline- so when you say it is ok at idle was that before, or after you richened it?

#4

Rennlist Member

Thread Starter

It was ok at idle, and then I richened it - scared ****less about how lean it got under any acceleration.

Then came the "oh ****" moment when i realized "yes i have a problem."

I replace the WUR, maybe in 2001? God, who can remember?

Pressure gauges will go on it Saturday.

I have read about a bit of blockage inthe WUR inlet screen filters that makes the control pressure too high. And that's what I think I have, too high control pressure not allowing the plunger to fully move to richen the mixture off idle.

If it is the WUR and too hard to fix, I've got my eye on Unwired Tools electronic WUR.

But I don't need to spend $500 this weekend.

Then came the "oh ****" moment when i realized "yes i have a problem."

I replace the WUR, maybe in 2001? God, who can remember?

Pressure gauges will go on it Saturday.

I have read about a bit of blockage inthe WUR inlet screen filters that makes the control pressure too high. And that's what I think I have, too high control pressure not allowing the plunger to fully move to richen the mixture off idle.

If it is the WUR and too hard to fix, I've got my eye on Unwired Tools electronic WUR.

But I don't need to spend $500 this weekend.

#5

Race Car

I've been hoping to read more about somebody trying one of those!

Its the quality of the basemaps (are they or not- ) and the degree of hoops that are (or are not) required for a good laptop tune that give me pause for use as a quick remedy.

Its the quality of the basemaps (are they or not- ) and the degree of hoops that are (or are not) required for a good laptop tune that give me pause for use as a quick remedy.

#6

Rennlist Member

Thread Starter

Well, it's not great news.

First, the pictures.

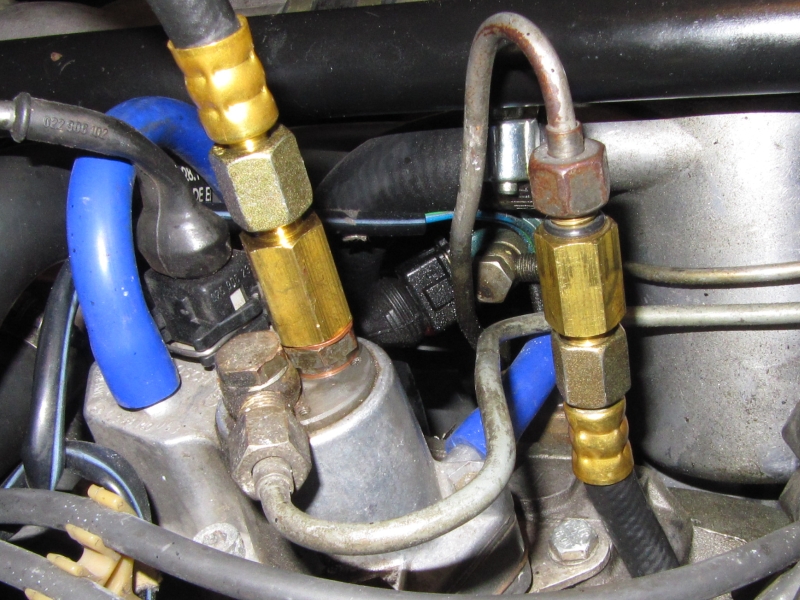

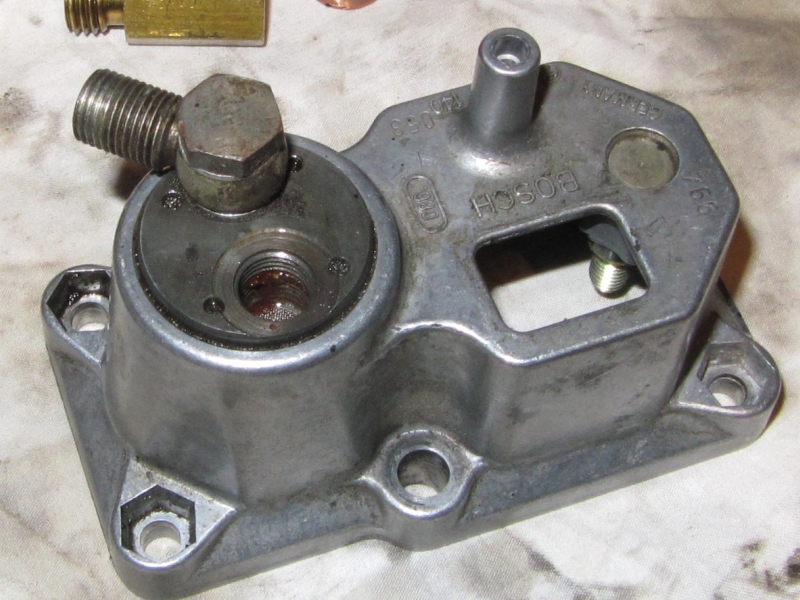

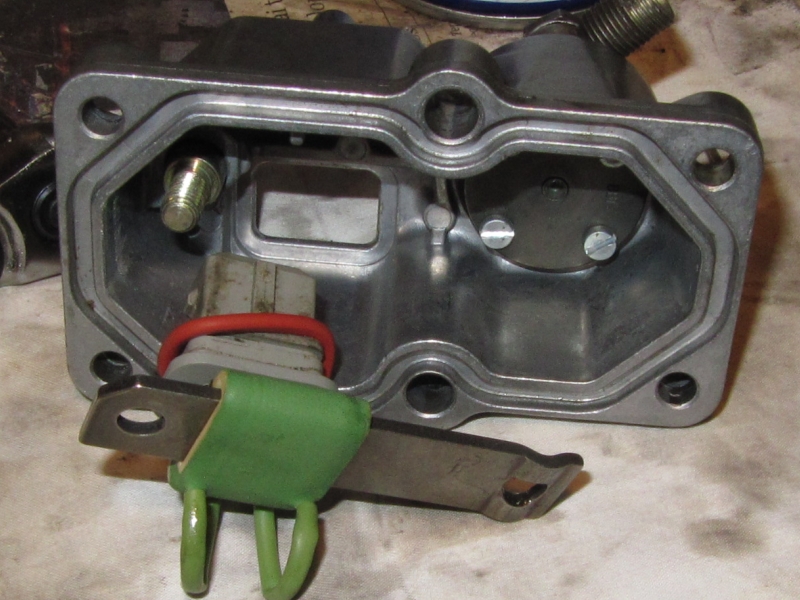

Here's the WUR in its natural habitat.

The top line in the photo is for the fuel distributor control pressure. The bottom is the return.

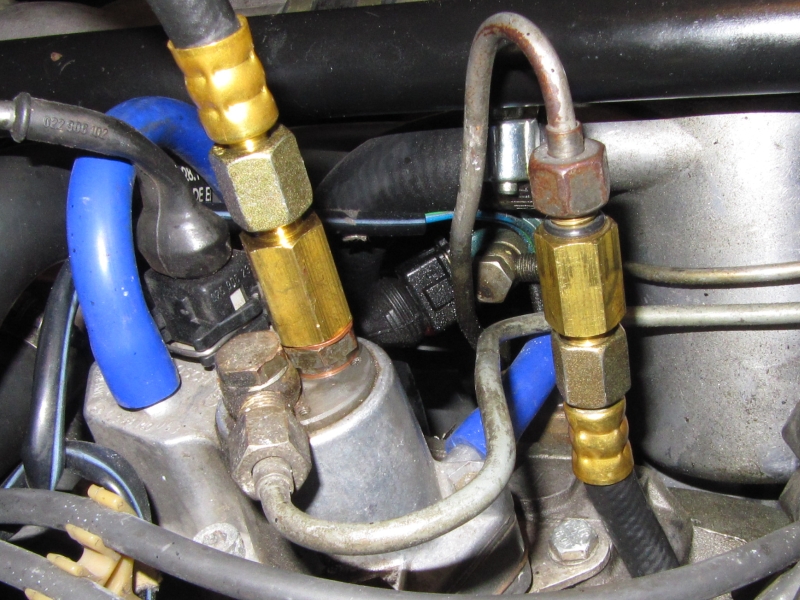

Here's my trusty JC Whitney CIS fuel pressure gauge.

Picture of the supplied adaptors I had to use.

Ready to go.

So here are the results.

Jumped the fuel pump, and got these readings.

57 deg F at the time, engine cold.

Control pressure 66lbs At that temp, should be about 20lbs.

At that temp, should be about 20lbs.

System pressure 85lbs Should be 65-75lbs. (I seem to remember it always being high)

Should be 65-75lbs. (I seem to remember it always being high)

Let it run a while to operating temp.

Control pressure 72lbs

Should be 40-46lbs

Should be 40-46lbs

System pressure 85lbs (still at one eek) should be 65-75lbs

(still at one eek) should be 65-75lbs

Got nice and hot too since my fan relay decided to burn out just at this time (actually lucky when I think about it).

Well, no wonder the damn thing is leaning out off idle.

Also, the vacuum hose connected to the top of WUR is giving 0 vacuum. The one lower on the WUR base is sending 16lbs vacuum. Both measured at idle. So I'll see what is up with that too.

So now time to figure out if the WUR has a a blockage on the return or just not regulating correctly.

Since the book shows control pressure to be about 61% of control, I figure I need about hot control pressure at 52lbs.

First, the pictures.

Here's the WUR in its natural habitat.

The top line in the photo is for the fuel distributor control pressure. The bottom is the return.

Here's my trusty JC Whitney CIS fuel pressure gauge.

Picture of the supplied adaptors I had to use.

Ready to go.

So here are the results.

Jumped the fuel pump, and got these readings.

57 deg F at the time, engine cold.

Control pressure 66lbs

At that temp, should be about 20lbs.

At that temp, should be about 20lbs.System pressure 85lbs

Should be 65-75lbs. (I seem to remember it always being high)

Should be 65-75lbs. (I seem to remember it always being high)Let it run a while to operating temp.

Control pressure 72lbs

Should be 40-46lbs

Should be 40-46lbsSystem pressure 85lbs

(still at one eek) should be 65-75lbs

(still at one eek) should be 65-75lbsGot nice and hot too since my fan relay decided to burn out just at this time (actually lucky when I think about it).

Well, no wonder the damn thing is leaning out off idle.

Also, the vacuum hose connected to the top of WUR is giving 0 vacuum. The one lower on the WUR base is sending 16lbs vacuum. Both measured at idle. So I'll see what is up with that too.

So now time to figure out if the WUR has a a blockage on the return or just not regulating correctly.

Since the book shows control pressure to be about 61% of control, I figure I need about hot control pressure at 52lbs.

#7

Shameful Thread Killer

Rennlist Member

Rennlist Member

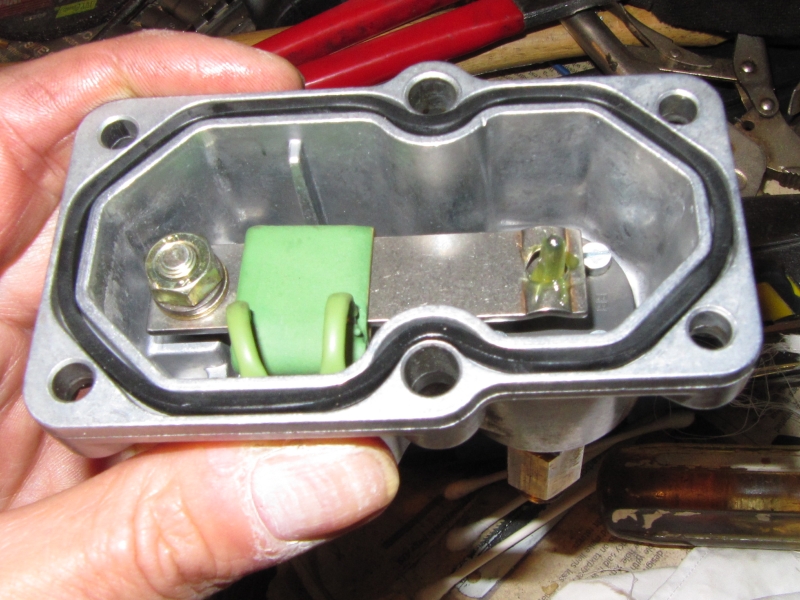

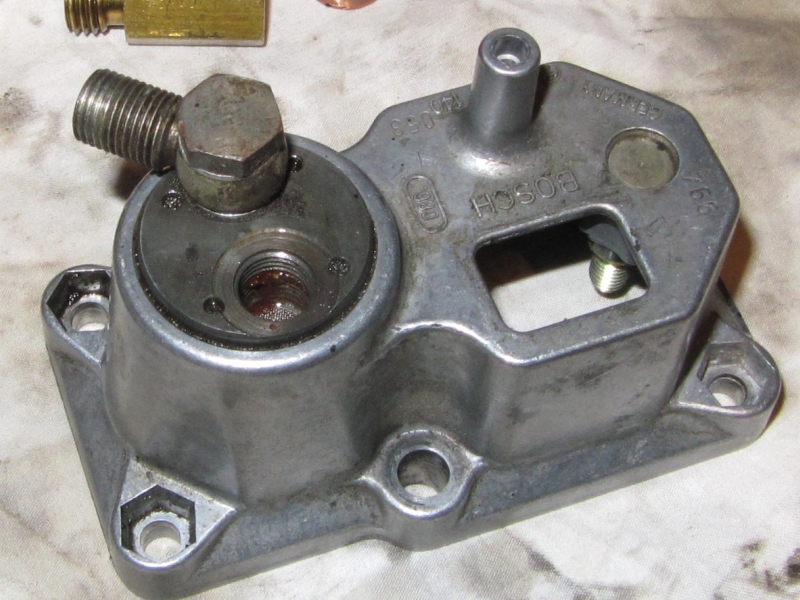

Take the WUR off the car, carefully disassemble it. Retain all the gaskets and seals. You may have to soak the housing in diesel fuel for a day to make it pliable. Once apart, clean everything. There is a bimetalic strip inside and the connections from the electric plug often get corroded and present hi resistance. Clean, clean, clean everything. Reassemble and try again. There are a few write ups on the WUR service here and at the Ferrarichat.com site.

The WUR is not regulating the pressure. Next, you have the fuel distributor head. On the side of it, there is a 17mm nut with a threaded shaft sticking out of it slightly. That is the primary pressure regulator. Loosen the nut and carefully remove the washer, the spring, and the ball inside. If the ball is stuck, that will also make your pressure too high. If the ball doesn't come out, you need to cover that threaded hole and run the fuel pump. Do NOT lose the ball! Once you have it out, clean, clean, clean inside there and then reassemble with the same number of washers on the spring stack. Now, test your pressures again. Leave the connector off the WUR so its not getting heat to the bimetalic strip and find your working pressure first. Then, go from there. If its still out of whack, report back with your findings. We may have to have you send your dist head to Sean for a refurb. That's a good idea anyway, once you have stuff apart.

Clean, clean, clean

<edit: found it, go here https://rennlist.com/forums/928-foru...ml#post9018365 it has pics too.>

The WUR is not regulating the pressure. Next, you have the fuel distributor head. On the side of it, there is a 17mm nut with a threaded shaft sticking out of it slightly. That is the primary pressure regulator. Loosen the nut and carefully remove the washer, the spring, and the ball inside. If the ball is stuck, that will also make your pressure too high. If the ball doesn't come out, you need to cover that threaded hole and run the fuel pump. Do NOT lose the ball! Once you have it out, clean, clean, clean inside there and then reassemble with the same number of washers on the spring stack. Now, test your pressures again. Leave the connector off the WUR so its not getting heat to the bimetalic strip and find your working pressure first. Then, go from there. If its still out of whack, report back with your findings. We may have to have you send your dist head to Sean for a refurb. That's a good idea anyway, once you have stuff apart.

Clean, clean, clean

<edit: found it, go here https://rennlist.com/forums/928-foru...ml#post9018365 it has pics too.>

Trending Topics

#9

Shameful Thread Killer

Rennlist Member

Rennlist Member

Remove it, box it and send it to Sean Ratts in Denton TX. It will never run right without the dist being setup right. Then, follow the inst on cleaning and repairing the WUR and try again.

With CIS, high pressure = lean as you've found out. The fuel dist has a differential pressure system on the metering pin. When the control pressure is too high, the air damper plate can't compensate for the fuel pressure on the metering pin. It has to be fixed, or you will detonate your engine eventually due to lean detonation or pre-ignition. It can be instantly fatal to an engine, or it can burn the top off the piston.

With CIS, high pressure = lean as you've found out. The fuel dist has a differential pressure system on the metering pin. When the control pressure is too high, the air damper plate can't compensate for the fuel pressure on the metering pin. It has to be fixed, or you will detonate your engine eventually due to lean detonation or pre-ignition. It can be instantly fatal to an engine, or it can burn the top off the piston.

#10

Rennlist Member

Thread Starter

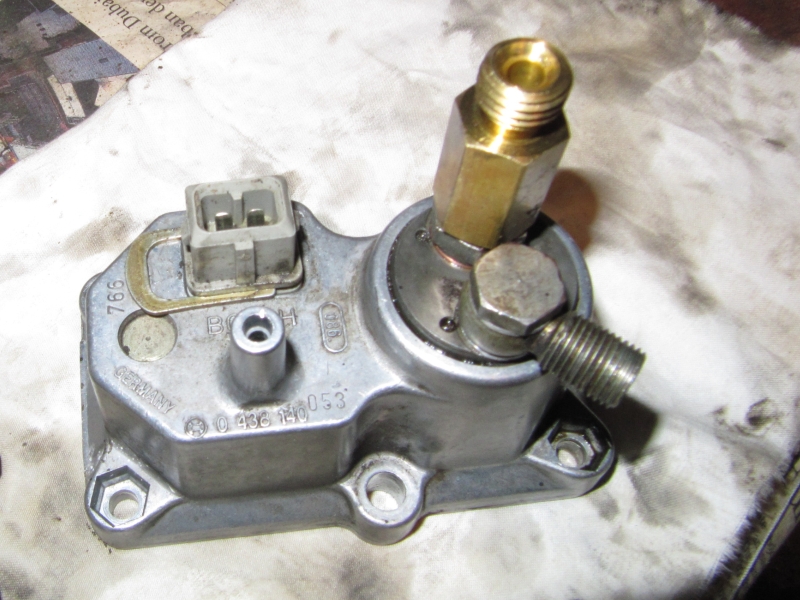

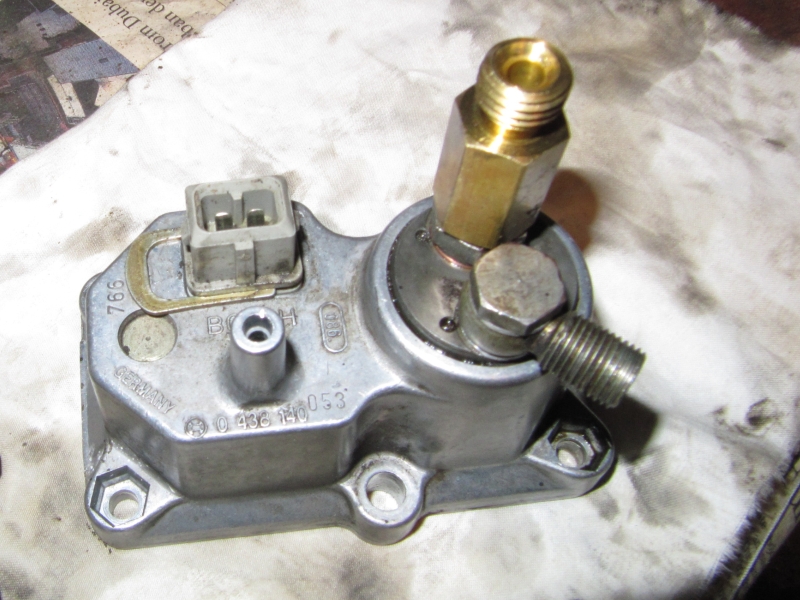

So, pull the WUR disassemble, clean and re-install.

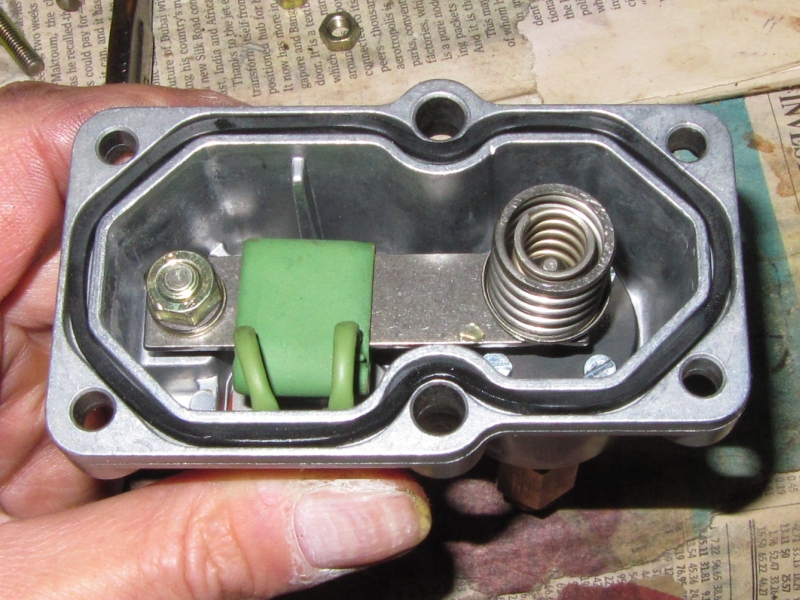

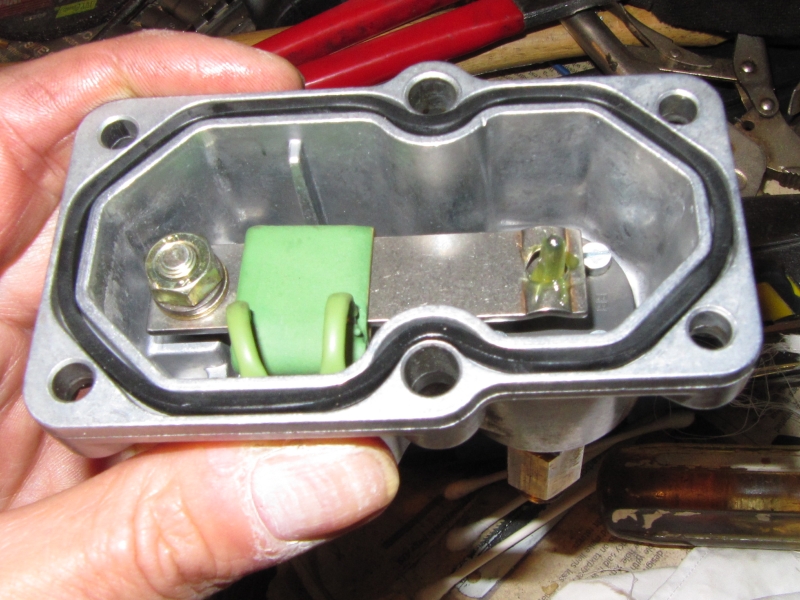

Remove the bottom plate, careful not to rip the gasket.

Remove the middle and top portions. The rod that adjusts pressure is sunk into a pool of grease.

Remove the heating element connector.

Unbolt and remove the strip.

What a mess in the inlet!

I removed the regulator diaphragm and CAREFULLY cleaned it as well as the inlet and outlet passages. Used rubbing alcohol and compressed air. Nice and clean.

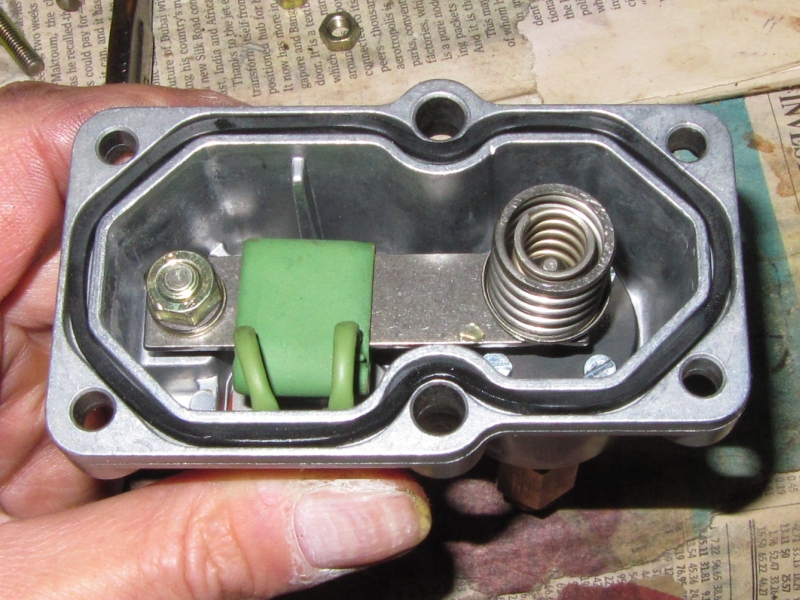

Then reassemble without the heating strip.

And check pressures (engine off, fuel pump jumpered).

Control Pressure 45 lbs (now we're talking)

System Pressure 85 lbs (no change really expected)

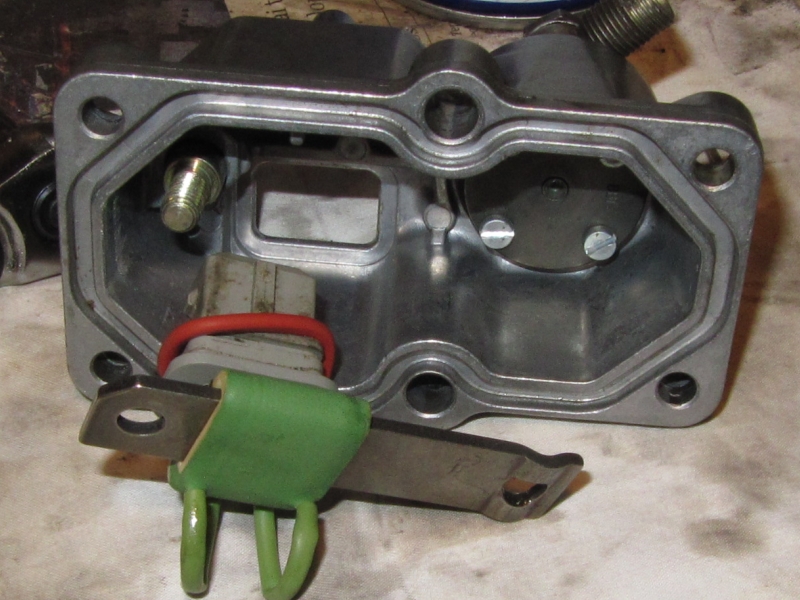

Remove, disassemble, and reassemble completely. The control rod goes on with the body upside down.

Then the cap and springs.

All ready to be reinstalled.

Final measurements.

Cold Control pressure 30 lbs

Warm Control pressure 44 lbs

System pressure 85 lbs.

YES!

Will fight the high system pressure another day, but wonder if this might cause the circuit to richen up a bit as the plate opens (not such a bad thing?)

Oh, and the lower vacuum hose increases control pressure with vacuum.

Remove the bottom plate, careful not to rip the gasket.

Remove the middle and top portions. The rod that adjusts pressure is sunk into a pool of grease.

Remove the heating element connector.

Unbolt and remove the strip.

What a mess in the inlet!

I removed the regulator diaphragm and CAREFULLY cleaned it as well as the inlet and outlet passages. Used rubbing alcohol and compressed air. Nice and clean.

Then reassemble without the heating strip.

And check pressures (engine off, fuel pump jumpered).

Control Pressure 45 lbs (now we're talking)

System Pressure 85 lbs (no change really expected)

Remove, disassemble, and reassemble completely. The control rod goes on with the body upside down.

Then the cap and springs.

All ready to be reinstalled.

Final measurements.

Cold Control pressure 30 lbs

Warm Control pressure 44 lbs

System pressure 85 lbs.

YES!

Will fight the high system pressure another day, but wonder if this might cause the circuit to richen up a bit as the plate opens (not such a bad thing?)

Oh, and the lower vacuum hose increases control pressure with vacuum.

#11

Shameful Thread Killer

Rennlist Member

Rennlist Member

Kewl. See that outlet screen in the 5th pic down? Make sure that isn't clogged. The high system pressure is related to the that ball check valve on the dist head. The nut and allen pin inside need to be taken out, cleaned and reinstalled. Don't lose the ball. If you need to change the sys pressure after that, we can adjust it with the allen plug, or a washer on the spring.

#12

Rennlist Member

Getting closer now. If you get system press down 10psi, the cold control should follow it down, but its the difference in system vs control that counts. You do need to fix the system pressure, as the opening pressure of the injectors is fixed at ~55psi. You can diagnose some where the pressure restriction is (per Watson) - with the guage set connected, showing control (pump jumpered, extinguisher handy), crack open the OUTLET at the Wur - if control doesnt drop, problem is in WUR; if it does drop, problem is further down the line; Crack open the WUR return line AT THE FD head - if control drops, problem is downwind - either the main regulator in the FD, or the return line at the tank . Crack open the tank return line at the FD, if control drops, problem is between there and the tank; if it doesnt problem is in the FD. Have the heater on the WUR disconnected or not powered through this. When my control got up around 60+psi (system of 75psi) I lost pretty much all power - max speed was around 20mph, with difficulty. I found the ONLY real way to clean the wur inlet screens was remove them and burn the crud off - one unit I have has FIVE layers of gauze.

jp 83 Euro S AT 54k.

jp 83 Euro S AT 54k.

#13

Shameful Thread Killer

Rennlist Member

Rennlist Member

I'm sorry but once again I must disagree with JP. Please see pic below. The sys pressure is set by the spring and ball in the side of the dist. It must be removed, checked, cleaned and installed then tested. Some owners mess with this spring or add washers to try fixing a FI problem. Get this cleaned and put back in with one washer and we will test again. The results of that test will determine if we adjust anything for the sys pressure. Do not start cracking lines and spraying fuel in the engine bay at 85PSI.

Last edited by docmirror; 05-02-2013 at 02:31 PM.

#14

Rennlist Member

I take Doc's point, but other blockages than something wrong in the FD main regulator CAN affect measured system pressure, because its dependent on a clear return path to the tank. Cracking open joints on a cold engine, with rags wrapped around joints to catch fuel has worked for me in the past, helping to localize a problem. One non-invasive procedure you could try is to load the tank with a solvent like berrymans and bridge the pump relay , and allow to run for some time, to try to dissolve crud in the lines.

jp 83 Euro S AT 54k.

jp 83 Euro S AT 54k.

#15

Racer

Adding washers is how you control pressure with this device, messing with the spring is not. I would add if you're going to be pulling it out and adjusting pressure then get the Bosch kit for it and do it right, with their washers and rings.