The secret behind the exhaust smoke upon startup 2.9L Caymans - An inconvenient truth

#32

Let me help you instead with your question...

In fact, the Subaru equivalent to the Porsche 2.9L 9A1 engine is the later Subaru 3.0L EZ30D engine (aka EZ30R) used until 2009 and updated from the early EZ30D used from 2001 to 2003. Both Porsche and Subaru engines are Multi Point Sequential Injection NA H6:

Porsche (Boxster version) is a 2893CC DOHC, 255 PS (187.5 kW) @6400rpm, 290Nm@4400 - 6000rpm. Bore 89.0mm, Stroke 77.5mm. Compression 11.5:1;

Subaru is a 2999CC DOHC, 250 PS (184 kW) @6600rpm, 297Nm@4200rpm. Bore 89.2mm, Stroke 80mm. Compression 10.7:1.

(The EZ30R equipes MY04+ Subaru Outback 3.0R, 2005-2009 (BL/BP) Legacy and Tribeca.)

The Subaru variable intake valve timing, AVCS (Active Valve Control System), and valve lift, AVLS (Active Valve Lift System), present on the later EZ30D engine is the VERY equivalent of Porsche's Variocam Plus technology - actually, they are exactly the same thing!!!

What is quite different though IS precisely the Subaru head gasket design that instead of restricting, as it happens with the Porsche engine, it actually enhances the coolant flow to cyl 6!!!

And why is that so important?! Well... overheating! You see...

- Coolant flow is not going through each cylinder one after the other but instead is split and a smaller amount is fed into different parts of the engine individually through cast in tubes in the cylinder block and cast in holes in the cylinder heads;

- Therefore, the size of the coolant holes in the head gaskets influences the amount of coolant in each cylinder;

- The coolant passages in the head gaskets seem to be all of the same size in the Porsche engine instead of all being different in area for different cylinder heads, namely the last cylinder - cyl. 6;

- Cyl. 6 is the most common one for failures as it is the furthest away from the coolest coolant (closest to the clutch end), thus running much nearer the safe temperature limits;

- Again, as the coolant travels along to each feeder hole towards the clutch end the coolant picks up the heat and the temperature rises reducing its cooling potential;

- Feed holes in the head gasket don't get progressively bigger towards the clutch end and thus are unable to provide higher coolant flow to compensate for the raised temperature - the area that controls the flow rate is proportional to that diameter increase squared;

- This will result in less well balanced cylinder temperature between different cylinders;

- So, in the Porsche engine greater temperature difference exists between where the coolant comes into the block and where it exits.

To better understand this, just take a look at the Subaru head gaskets design (for both cylinder banks) and then compare it to the Porsche head gasket:

Subaru's passenger side head gasket. Corresponds to cylinders 2, 4, and 6 from left to right:

Subaru's driver side head gasket. Corresponds to cylinders 5, 3, and 1 from left to right:

2.9 Cayman's passenger side head gasket. Corresponds to cylinders 3, 2 and 1 from left to right:

The cylinder numbering is different Subaru to Porsche but what you can clearly see is that there is two big slots in each Subaru's head gasket surrounding cylinder 5 and cylinder 6 (corresponding to Porsche's cylinders 6 and 3, respectively) which are precisely the ones furthest away from the coolest coolant (closest to the clutch end). Thus, to compensate for the raised temperature higher coolant flow is provided for Subaru's cylinder 6 (and also cylinder 5) by means of the much larger area of those two slots combined instead of the equal-sized holes (front to back) in the Porsche head gasket.

Ironically, it's the HG itself that has been the longevity problem with Subaru's H6, failures starting to occur around 150k/160k miles along with the 10 year mark.

Last edited by CaymanPower; 04-18-2012 at 06:20 AM.

#33

Race Director

Not sure your using the Subie and its head gasket failure at 100K to 150K miles makes a good argument for your point.

Head gasket failure points to uneven heating/cooling occurring which results in the two mating parts moving relative to each other and the gasket and over time this degrades the gasket to the point it leaks.

Furthermore, uneven heating can result in localized hot spots which over time work to reduce the clamping force of the head bolts/studs+nuts in those areas with possible head gasket failure the result.

What I vaguely recall about your situation was the engine had a new engine problem and the dealer was less than sympathetic to your car's plight. Absent any symptoms or behavior set forth by the factory the dealer can be limited in how it can respond.

A good (or better) dealer could have pushed the factory harder on your behalf. It didn't. (Or maybe it couldn't.)

IIRC you tore down the engine and were unable to determine what was going on.

You managed to get the engine back together and after some more discussion with the dealer the dealer/factory agreed to replace the pistons and IIRC the smoking went away.

But you rid yourself of the car. I intend no reproach by stating this. That you elected to get rid of the car is understandable given what you went through.

A neighbor of mine had a BMW which he had some issues with and the dealer was unable to address them to his satisfaction and the neighbor ended up getting rid of the BMW for an Audi which he simply loved. For good reason: the Audi proved to be a good car (though from what I knew about the situation the BMW was not a bad car, the dealer was the problem). The neighbor and the BMW were just not meant to be...

Sincerely,

Macster.

Head gasket failure points to uneven heating/cooling occurring which results in the two mating parts moving relative to each other and the gasket and over time this degrades the gasket to the point it leaks.

Furthermore, uneven heating can result in localized hot spots which over time work to reduce the clamping force of the head bolts/studs+nuts in those areas with possible head gasket failure the result.

What I vaguely recall about your situation was the engine had a new engine problem and the dealer was less than sympathetic to your car's plight. Absent any symptoms or behavior set forth by the factory the dealer can be limited in how it can respond.

A good (or better) dealer could have pushed the factory harder on your behalf. It didn't. (Or maybe it couldn't.)

IIRC you tore down the engine and were unable to determine what was going on.

You managed to get the engine back together and after some more discussion with the dealer the dealer/factory agreed to replace the pistons and IIRC the smoking went away.

But you rid yourself of the car. I intend no reproach by stating this. That you elected to get rid of the car is understandable given what you went through.

A neighbor of mine had a BMW which he had some issues with and the dealer was unable to address them to his satisfaction and the neighbor ended up getting rid of the BMW for an Audi which he simply loved. For good reason: the Audi proved to be a good car (though from what I knew about the situation the BMW was not a bad car, the dealer was the problem). The neighbor and the BMW were just not meant to be...

Sincerely,

Macster.

#34

That's really your problem man... you don't need to 'vaguely recall' because by doing so your statements will always be inevitably inaccurate.

All you need to do is to read the thread you are posting in... I mean, really read for your posts to make any sense at all.

Again you are mistaken because you didn't read... my point is simply this:

No matter what brand Subaru, BMW, Audi or Porsche I will ALWAYS be a happy customer if a failure will ONLY occur after 150k/160k miles (where did you see 100k?!?!... again you didn't read) and after 10 years of reliable performance... you see, I never kept a car for so long anyway... let alone for longer.

As far as I'm concerned it's perfectly acceptable a head gasket failure after that long... however, what is NOT acceptable at all is bad pistons from new and worst still, without public acknowledgement by the brand... but that it's just me!

Are you reading now?!

All you need to do is to read the thread you are posting in... I mean, really read for your posts to make any sense at all.

No matter what brand Subaru, BMW, Audi or Porsche I will ALWAYS be a happy customer if a failure will ONLY occur after 150k/160k miles (where did you see 100k?!?!... again you didn't read) and after 10 years of reliable performance... you see, I never kept a car for so long anyway... let alone for longer.

As far as I'm concerned it's perfectly acceptable a head gasket failure after that long... however, what is NOT acceptable at all is bad pistons from new and worst still, without public acknowledgement by the brand... but that it's just me!

Are you reading now?!

#35

Nordschleife Master

That's really your problem man... you don't need to 'vaguely recall' because by doing so your statements will always be inevitably inaccurate.

All you need to do is to read the thread you are posting in... I mean, really read for your posts to make any sense at all.

Again you are mistaken because you didn't read... my point is simply this:

No matter what brand Subaru, BMW, Audi or Porsche I will ALWAYS be a happy customer if a failure will ONLY occur after 150k/160k miles (where did you see 100k?!?!... again you didn't read) and after 10 years of reliable performance... you see, I never kept a car for so long anyway... let alone for longer.

As far as I'm concerned it's perfectly acceptable a head gasket failure after that long... however, what is NOT acceptable at all is bad pistons from new and worst still, without public acknowledgement by the brand... but that it's just me!

Are you reading now?!

All you need to do is to read the thread you are posting in... I mean, really read for your posts to make any sense at all.

Again you are mistaken because you didn't read... my point is simply this:

No matter what brand Subaru, BMW, Audi or Porsche I will ALWAYS be a happy customer if a failure will ONLY occur after 150k/160k miles (where did you see 100k?!?!... again you didn't read) and after 10 years of reliable performance... you see, I never kept a car for so long anyway... let alone for longer.

As far as I'm concerned it's perfectly acceptable a head gasket failure after that long... however, what is NOT acceptable at all is bad pistons from new and worst still, without public acknowledgement by the brand... but that it's just me!

Are you reading now?!

This thread is like herpes. Someone make it go away.

Last edited by orthojoe; 04-18-2012 at 11:00 PM.

#37

Addict

Rennlist Member

Rennlist Member

Dude, what is your problem? You come off as an obsessed maniac. You've already been banned from planet-9. What are you trying to accomplish here other than insult people? You've made your point and opinion known. Now let it die.

This thread is like herpes. Someone make it go away.

This thread is like herpes. Someone make it go away.

CaymanPower, it is obvious that you were burned by Porsche and you're not happy about it. I'm sure nearly all of us have been burned at some point or another by a car manufacturer. I was burned by VW and trust me the issues I had were just as bad as your Cayman. But you won't see me popping up on VW Forums to trash talk the car. For me it was a lesson learned and I moved on. I suggest you do the same. Dwelling on this is not good for you and honestly I don't think it brings any real value, especially when you start comparing a Subaru engine to the 987 engine.

Let it go.

#38

Nordschleife Master

The guy is nuts. I'm not sure if he realizes he's talking/arguing with himself most of the time. I would suggest that we all 'egg' him on so he can write pages upon pages of banter....but that just wouldn't help....

#39

I think I have that right!

#40

I put this guy on "ignore"

recommend mods give him the boot, or maybe a launch!

recommend mods give him the boot, or maybe a launch!

#41

Nordschleife Master

Ah, so this is the problem... but what I forgot to mention and why this comparison is so important is the fact that the common issue with this Subaru engine is the head gasket failure around 150k/160k miles along with the 10 year mark and despite we are ALSO talking about a flat H6 engine it doesn't smoke upon startup unless it reaches that kind of mileage due to the NORMAL cylinder bore/piston rings wear. As for the 2.9 Porsche's 9A1 H6 engine it smokes upon startup from new due to... well, that's what I'm trying to explain and what this thread is all about - no less, no more.

I think I have that right!

I think I have that right!

(great advice, JSF)

#42

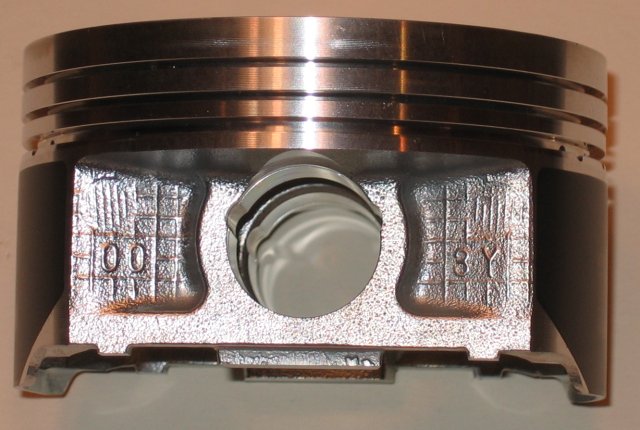

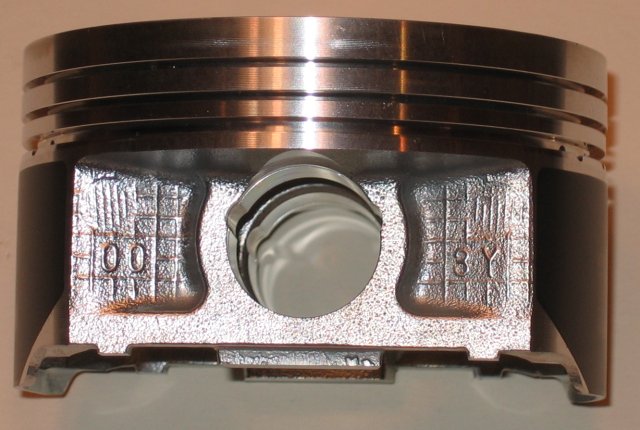

Talking about bad pistons… again, we can compare Subaru’s pistons from the EZ30R engine to the Porsche 9A1 engine’s pistons (see pictures below). What we realize is that Subaru engine has (1) cast pistons while the Porsche’s pistons are forged, (2) four oil drain back holes per side while the Porsche’s pistons have only two per side and (3) no oil squirters whereas the Porsche engine has oil squirters to cool the pistons. The Subaru pistons run in (4) cast iron cylinder liners while the Porsche pistons run in ALUSIL bores. So, what does it all mean?

No matter which piston you use, and no matter which engine a piston goes into they are all made from a combination of both aluminium and silicon. It is the amount of silicon though, which determines the pistons overall strength verses wear resistance properties. Silicon also controls the rate of expansion of the piston as the material becomes hotter (the less expansion then better!).

So it is not the forging, but the alloy selected that dominates the expansion coefficients and thus the piston to cylinder clearances required. More silicon means lower expansion coefficient. Silicon content makes a big difference requiring that adjustments must be made in piston to bore clearance as the amount of silicon in the alloy is changed. Forged pistons expand and contract more under changing temperatures, so they traditionally require greater piston-to-wall clearance than cast pistons.

However, forgings have inherent advantages in terms of density, ultimate strength, and durability. Forging eliminates metal porosity and improves ductility. One of the most important characteristics of forged pistons is what happens at the point of piston failure. Under extreme conditions—like detonation—forgings tend to “go plastic” and fail gradually.

In the forging process the rough casting is placed in a die set while it is still hot and semi-solid. A hydraulic press is used to place the rough slug under tremendous pressure. This removes any possible porosity and also pushes the alloy grains together tighter than can be achieved by simple casting alone. The result is a much stronger material.

Forged pistons are formed using a giant press that takes a block of metal and pounds it into shape under thousands of tons of pressure. The tooling needed to do this is much more expensive than the tooling used to make a casting, and it wears out quicker. This makes forged pistons more costly than castings. Because higher silicon contents make the alloy harder and more brittle, alloys used in forging are necessarily lower in silicon and typically have higher expansion coefficients.

Forged pistons are generally made from one of few different aluminum alloys, with each offering different benefits depending on the application. The two most popular alloys are 4032 and 2618. Although ‘2618’ has better high-temperature characteristics, it contains virtually no silicon, it has less than 2% silicon and could be described as hypo (under) eutectic. The low-silicon content causing the extra heat-expansion, these pistons have their cylinders bored to a very loose cold-fit. This leads to a condition where the piston rocks in the cylinder and it causes an audible tapping noise that continues until the engine has warmed to operational temperatures. These engines should not be revved when cold, or excessive scuffing can occur. The ‘4032’ piston alloy has a silicon content of approximately 11%. This means that it expands less than a piston with no silicon and since the silicon is fully alloyed on a molecular level (eutectic), the alloy is less brittle and more flexible than a hypereutectic cast piston. These pistons can survive mild detonation with less damage than cast pistons. Unless something else goes wrong, this is not such a huge bonus as the engine should be tuned not to detonate in the first place. It’s in extremely high rpm/high horsepower applications where the great strength of the forged piston can add reliability.

Hypereutectic pistons (high degree of free undissolved silicon in the end piston, something around the 16-18 per cent mark) can be forged but typically are only cast because the extra expense of forging is not justified when cast pistons are considered strong enough for stock applications. The higher silicon content in the hypereutectic alloy lends itself to improved scuff resistance and, importantly, a relatively low expansion rate. If higher piston strength is needed, then generally, a piston manufacturer will add more copper and nickel to the alloy to gain extra high temperature strength. It doesn’t have the ductility of the forging, but for those who are really good at managing their motors, it’s a product that can race with tight tolerances. Today’s computer-controlled engines are more carefully and precisely managed, allowing a greater range of performance than ever thought possible. Today turbos, small-displacement motors and high horsepower is the norm. The OEs are running cast pistons yet they’re making more high horsepower, high-output, small motors than ever before!

The major disadvantages to forged pistons are actually a result of the forging process itself. Forging results in a piston that is normally heavier than cast pistons, and is limited in the aluminum alloys that can be used to produce the piston. Additionally, the forging process also limits the design configuration of the piston itself. A die for forged piston must be designed so it can easily be removed and, as a result, the forged blank (or unfinished piston) has a relative simple shape. Casting can achieve a more complex blank and, therefore, facilitate lightweight construction. It is not so much what material pistons are made from but their physical design that it will determine ultimate durability and whether they are going to break/seize. Piston skirt profiling has given piston makers the ability to finely adjust skirt contact areas for more even loading. Barrel-type profiles now accommodate greater expansion at operating temperature even if the forging process and its limited choice of aluminum alloys result in a dramatically higher expansion rate for the forged piston. One result is that today’s short-skirted pistons have better contact areas than the old long-skirt designs, and wear is reduced even as piston-to-wall clearances are tightened up. The shift is definitely toward piston architecture!

In the past it was common for forged-piston materials to contain only 7 per cent silicon in their make-up. This led to high temperature expansion rates, making engines sound 'rattly' when started cold. This meant that break-in and warm up periods were crucial for the forged piston. The forged piston had 10 times more clearance in the cylinder. This resulted in less ring stability against the cylindrical wall, more piston noise and extra blow-by. The Germans came with new materials for forged pistons which did away with the undesirable expansion rates, by containing a much more acceptable 14 per cent silicon content. As some top-level german cars have forged pistons standard it was a requirement that these engines remained smooth and quiet along with more stringent emission characteristics, even when cold - hence the development of better materials.

By adding silicon to the piston's alloy, the piston expansion was dramatically reduced. This allowed engineers to specify a much tighter cold-fit between the piston and the cylinder liner. Silicon itself expands less than aluminium but it also acts as an insulator to prevent the aluminium from absorbing as much of the operational heat as it otherwise would. As performance goes up, the piston tends to run hotter. Another benefit of adding silicon is that the piston becomes harder and is less susceptible to scuffing which can occur when a soft aluminium piston is cold-revved in a relatively dry cylinder on start-up OR during abnormally high operating temperatures.

With hypereutectic pistons, the primary reason for having all of this free silicon is to tightened up piston-to-wall clearances and reduce piston ring groove distortion that leads to ring land breakage (the metal section separating the ring grooves). This allows piston designers to run much smaller, thinner piston ring lands and move the top compression ring much farther up the side of the piston (where combustion temperatures are much hotter). The reason piston designers want to do this is that it allows a lighter piston to be produced, and also has dramatic results in changing engine emission characteristics. As emission laws become tougher, it will be commonplace to find true hypereutectic pistons in road engines.

So pistons used by OEMs today are of the hypereutectic type because this allows better noise control and gives advantages in ring designs and fuel emissions standards. The machining process does need to be more consistent when a hypereutectic product is used - holding tolerances in the millionths - because it starts with a closer piston-to-wall clearance. If somehow these tolerances no longer hold true it’s VERY likely that damage will occur but this can happen in stages and the smoke upon start up will be the VERY first symptom!

Subaru's piston:

Porsche's pistons:

Subaru's piston:

Porsche's pistons:

Subaru's piston:

Porsche's pistons:

No matter which piston you use, and no matter which engine a piston goes into they are all made from a combination of both aluminium and silicon. It is the amount of silicon though, which determines the pistons overall strength verses wear resistance properties. Silicon also controls the rate of expansion of the piston as the material becomes hotter (the less expansion then better!).

So it is not the forging, but the alloy selected that dominates the expansion coefficients and thus the piston to cylinder clearances required. More silicon means lower expansion coefficient. Silicon content makes a big difference requiring that adjustments must be made in piston to bore clearance as the amount of silicon in the alloy is changed. Forged pistons expand and contract more under changing temperatures, so they traditionally require greater piston-to-wall clearance than cast pistons.

However, forgings have inherent advantages in terms of density, ultimate strength, and durability. Forging eliminates metal porosity and improves ductility. One of the most important characteristics of forged pistons is what happens at the point of piston failure. Under extreme conditions—like detonation—forgings tend to “go plastic” and fail gradually.

In the forging process the rough casting is placed in a die set while it is still hot and semi-solid. A hydraulic press is used to place the rough slug under tremendous pressure. This removes any possible porosity and also pushes the alloy grains together tighter than can be achieved by simple casting alone. The result is a much stronger material.

Forged pistons are formed using a giant press that takes a block of metal and pounds it into shape under thousands of tons of pressure. The tooling needed to do this is much more expensive than the tooling used to make a casting, and it wears out quicker. This makes forged pistons more costly than castings. Because higher silicon contents make the alloy harder and more brittle, alloys used in forging are necessarily lower in silicon and typically have higher expansion coefficients.

Forged pistons are generally made from one of few different aluminum alloys, with each offering different benefits depending on the application. The two most popular alloys are 4032 and 2618. Although ‘2618’ has better high-temperature characteristics, it contains virtually no silicon, it has less than 2% silicon and could be described as hypo (under) eutectic. The low-silicon content causing the extra heat-expansion, these pistons have their cylinders bored to a very loose cold-fit. This leads to a condition where the piston rocks in the cylinder and it causes an audible tapping noise that continues until the engine has warmed to operational temperatures. These engines should not be revved when cold, or excessive scuffing can occur. The ‘4032’ piston alloy has a silicon content of approximately 11%. This means that it expands less than a piston with no silicon and since the silicon is fully alloyed on a molecular level (eutectic), the alloy is less brittle and more flexible than a hypereutectic cast piston. These pistons can survive mild detonation with less damage than cast pistons. Unless something else goes wrong, this is not such a huge bonus as the engine should be tuned not to detonate in the first place. It’s in extremely high rpm/high horsepower applications where the great strength of the forged piston can add reliability.

Hypereutectic pistons (high degree of free undissolved silicon in the end piston, something around the 16-18 per cent mark) can be forged but typically are only cast because the extra expense of forging is not justified when cast pistons are considered strong enough for stock applications. The higher silicon content in the hypereutectic alloy lends itself to improved scuff resistance and, importantly, a relatively low expansion rate. If higher piston strength is needed, then generally, a piston manufacturer will add more copper and nickel to the alloy to gain extra high temperature strength. It doesn’t have the ductility of the forging, but for those who are really good at managing their motors, it’s a product that can race with tight tolerances. Today’s computer-controlled engines are more carefully and precisely managed, allowing a greater range of performance than ever thought possible. Today turbos, small-displacement motors and high horsepower is the norm. The OEs are running cast pistons yet they’re making more high horsepower, high-output, small motors than ever before!

The major disadvantages to forged pistons are actually a result of the forging process itself. Forging results in a piston that is normally heavier than cast pistons, and is limited in the aluminum alloys that can be used to produce the piston. Additionally, the forging process also limits the design configuration of the piston itself. A die for forged piston must be designed so it can easily be removed and, as a result, the forged blank (or unfinished piston) has a relative simple shape. Casting can achieve a more complex blank and, therefore, facilitate lightweight construction. It is not so much what material pistons are made from but their physical design that it will determine ultimate durability and whether they are going to break/seize. Piston skirt profiling has given piston makers the ability to finely adjust skirt contact areas for more even loading. Barrel-type profiles now accommodate greater expansion at operating temperature even if the forging process and its limited choice of aluminum alloys result in a dramatically higher expansion rate for the forged piston. One result is that today’s short-skirted pistons have better contact areas than the old long-skirt designs, and wear is reduced even as piston-to-wall clearances are tightened up. The shift is definitely toward piston architecture!

In the past it was common for forged-piston materials to contain only 7 per cent silicon in their make-up. This led to high temperature expansion rates, making engines sound 'rattly' when started cold. This meant that break-in and warm up periods were crucial for the forged piston. The forged piston had 10 times more clearance in the cylinder. This resulted in less ring stability against the cylindrical wall, more piston noise and extra blow-by. The Germans came with new materials for forged pistons which did away with the undesirable expansion rates, by containing a much more acceptable 14 per cent silicon content. As some top-level german cars have forged pistons standard it was a requirement that these engines remained smooth and quiet along with more stringent emission characteristics, even when cold - hence the development of better materials.

By adding silicon to the piston's alloy, the piston expansion was dramatically reduced. This allowed engineers to specify a much tighter cold-fit between the piston and the cylinder liner. Silicon itself expands less than aluminium but it also acts as an insulator to prevent the aluminium from absorbing as much of the operational heat as it otherwise would. As performance goes up, the piston tends to run hotter. Another benefit of adding silicon is that the piston becomes harder and is less susceptible to scuffing which can occur when a soft aluminium piston is cold-revved in a relatively dry cylinder on start-up OR during abnormally high operating temperatures.

With hypereutectic pistons, the primary reason for having all of this free silicon is to tightened up piston-to-wall clearances and reduce piston ring groove distortion that leads to ring land breakage (the metal section separating the ring grooves). This allows piston designers to run much smaller, thinner piston ring lands and move the top compression ring much farther up the side of the piston (where combustion temperatures are much hotter). The reason piston designers want to do this is that it allows a lighter piston to be produced, and also has dramatic results in changing engine emission characteristics. As emission laws become tougher, it will be commonplace to find true hypereutectic pistons in road engines.

So pistons used by OEMs today are of the hypereutectic type because this allows better noise control and gives advantages in ring designs and fuel emissions standards. The machining process does need to be more consistent when a hypereutectic product is used - holding tolerances in the millionths - because it starts with a closer piston-to-wall clearance. If somehow these tolerances no longer hold true it’s VERY likely that damage will occur but this can happen in stages and the smoke upon start up will be the VERY first symptom!

Subaru's piston:

Porsche's pistons:

Subaru's piston:

Porsche's pistons:

Subaru's piston:

Porsche's pistons:

Last edited by CaymanPower; 04-19-2012 at 03:45 PM.

#44

The next picture shows how Subaru redesigned the cooling system from the EZ30D engine in their newer EZ36D engine (which was introduced in 2008) by routing 80 percent of the engine’s cooling capacity to the head to allow engineers to advance timing in the low-to-mid rpm range of the engine and increase torque without inducing knock. This allows for increased engine efficiency and better emissions standards. Additionally, Subaru altered the cooling system from one where cylinders receive the coolant flow sequentially to one where separate ducts provide each cylinder with its own fresh supply - a common rail cooling system that individually cools each cylinder rather than allowing water to flow from cylinder to cylinder (as pictured on the right).

If you follow the flow chart on the right (EZ30D engine) you will see that the coolant first enters the cylinders from the bottom - the hotter exhaust side - then it flows from the front of the engine to the rear cylinders and from that point, up through the heads (rear head gasket slots) and then in the opposite direction from the rear of the head to the front where it exits to the radiator through the water pipe connected to each side. And, while it is true that the coolant progressively picks up heat as it flows through the block, coolant flow will always be HIGH enough for the rearward cylinders to NEVER get hot and bothered because all the coolant is routed to the cylinders before it even reaches the heads.

On the other hand, with the new cooling system there's significantly less coolant flow to the cylinders and much more to the heads. Thus, the cylinders run much hotter and closer to the safe limits. The difference in temperatures from one cylinder to another is decreased by as much as 50% due largely to this effect even though the flow pattern has each cylinder being fed from the block individually and water then leaving the cylinders to return out the heads around the middle for a more-equal cooling strategy as pictured on the left.

Add this to the fact that in order to keep the EZ36D engine roughly the same size as its predecessor, Subaru engineers increased its bore and stroke while reducing the distance between the edges of the cylinders and shortening the con rods to allow for the larger displacement, then you easily understand why this engine IS an oil drinker!

In fact, not only the cylinders run now much hotter due to the new cooling system but the rod to stroke ratio is now also lower by virtue of the shortened rod length and increased stroke - rod angularity becomes too great and a greater potential for accelerated wear to cylinder walls, pistons and piston rings exists, the rod angle must not encourage excessive friction at the cylinder wall and piston skirt.

So, what was once a VERY reliable engine (the EZ30D) has turned into a... well you know... despite the power and torque advantage and all the technological goodies such as Active Valve Control System (AVCS) variable valve timing on both the intake and exhaust valves (the 3.0-liter engine had AVCS on the intake side only).

As owners started to complain about high oil consumption issues it didn't take long for a TSB to appear for the 3.6-liter H6 engine (at least they had one):

Subaru on oil consumption:

Porsche says in the owners manual that an oil consumption rate of 1.5 liter per 1,000 kilometers is still acceptable... go figure!!!

Any similarities that you may perceive as existing between Porsche and Subaru H6 engines are NO coincidence... nor is the differences.

If you follow the flow chart on the right (EZ30D engine) you will see that the coolant first enters the cylinders from the bottom - the hotter exhaust side - then it flows from the front of the engine to the rear cylinders and from that point, up through the heads (rear head gasket slots) and then in the opposite direction from the rear of the head to the front where it exits to the radiator through the water pipe connected to each side. And, while it is true that the coolant progressively picks up heat as it flows through the block, coolant flow will always be HIGH enough for the rearward cylinders to NEVER get hot and bothered because all the coolant is routed to the cylinders before it even reaches the heads.

On the other hand, with the new cooling system there's significantly less coolant flow to the cylinders and much more to the heads. Thus, the cylinders run much hotter and closer to the safe limits. The difference in temperatures from one cylinder to another is decreased by as much as 50% due largely to this effect even though the flow pattern has each cylinder being fed from the block individually and water then leaving the cylinders to return out the heads around the middle for a more-equal cooling strategy as pictured on the left.

Add this to the fact that in order to keep the EZ36D engine roughly the same size as its predecessor, Subaru engineers increased its bore and stroke while reducing the distance between the edges of the cylinders and shortening the con rods to allow for the larger displacement, then you easily understand why this engine IS an oil drinker!

In fact, not only the cylinders run now much hotter due to the new cooling system but the rod to stroke ratio is now also lower by virtue of the shortened rod length and increased stroke - rod angularity becomes too great and a greater potential for accelerated wear to cylinder walls, pistons and piston rings exists, the rod angle must not encourage excessive friction at the cylinder wall and piston skirt.

So, what was once a VERY reliable engine (the EZ30D) has turned into a... well you know... despite the power and torque advantage and all the technological goodies such as Active Valve Control System (AVCS) variable valve timing on both the intake and exhaust valves (the 3.0-liter engine had AVCS on the intake side only).

As owners started to complain about high oil consumption issues it didn't take long for a TSB to appear for the 3.6-liter H6 engine (at least they had one):

Service Bulletin #02-105-08

Cylinder Block and Piston Design Change

Bulletin Description: The purpose of this bulletin is to inform that the cylinder block journal and piston skirt design has been changed. As a result, the ECM logic was also changed. This bulletin provides the new part numbers, countermeasure in production, interchangeability of parts and ECM reprogramming information.

Cylinder Block and Piston Design Change

Bulletin Description: The purpose of this bulletin is to inform that the cylinder block journal and piston skirt design has been changed. As a result, the ECM logic was also changed. This bulletin provides the new part numbers, countermeasure in production, interchangeability of parts and ECM reprogramming information.

Subaru on oil consumption:

NOTE

* When the engine low oil level warning

light illuminates, have your vehicle

inspected by your SUBARU dealer as

soon as possible.

** The engine oil consumption rate is

not stabilized, and therefore cannot be

determined until the vehicle has traveled

at least several thousand miles

(kilometers). Even after break-in, when

the vehicle is used under severe driving

conditions such as those mentioned

in the Warranty and Maintenance

Booklet, engine oil is consumed

or deteriorated more quickly than under

normal driving conditions. If you

drive your vehicle under these severe

conditions, you should check the oil

level at least at every second fuel fill-up

time, and change the oil more frequently.

Please refer to the Warranty

and Maintenance Booklet for more details.

*** If the oil consumption rate seems

abnormally high after the break-in

period, for example more than 1 quart

per 1,200 miles or 1 liter per 2,000

kilometers, we recommend that you

contact your SUBARU dealer.

* When the engine low oil level warning

light illuminates, have your vehicle

inspected by your SUBARU dealer as

soon as possible.

** The engine oil consumption rate is

not stabilized, and therefore cannot be

determined until the vehicle has traveled

at least several thousand miles

(kilometers). Even after break-in, when

the vehicle is used under severe driving

conditions such as those mentioned

in the Warranty and Maintenance

Booklet, engine oil is consumed

or deteriorated more quickly than under

normal driving conditions. If you

drive your vehicle under these severe

conditions, you should check the oil

level at least at every second fuel fill-up

time, and change the oil more frequently.

Please refer to the Warranty

and Maintenance Booklet for more details.

*** If the oil consumption rate seems

abnormally high after the break-in

period, for example more than 1 quart

per 1,200 miles or 1 liter per 2,000

kilometers, we recommend that you

contact your SUBARU dealer.

Porsche says in the owners manual that an oil consumption rate of 1.5 liter per 1,000 kilometers is still acceptable... go figure!!!

Any similarities that you may perceive as existing between Porsche and Subaru H6 engines are NO coincidence... nor is the differences.

Last edited by CaymanPower; 05-01-2012 at 10:33 AM.

#45

AutoX

I agree that Cayman Power's tone is uncalled for, but his points I believe are valid. I remain concerned that my boxster's engine life will be shorter than a 3.4 because of the problems he has discovered. I just wish that there was a way for all of us with these smoking 2.9's could have them corrected by Porsche without going thru all of the repeated hassel, My only help is that my car is CPO good till August 2014.

I really appreciate the help that everyone including Cayman Power has given me on this and Planet 9.

My only hope is that civility on the post will prevail.

Darrel

I really appreciate the help that everyone including Cayman Power has given me on this and Planet 9.

My only hope is that civility on the post will prevail.

Darrel