blown engine

#301

I would think for a street car , cast cylinder sleeves would be an option with stock pistons and aftermarket piston rings .That would put a big dent in the cost .Worth at least a phone call to LA sleeve and find out their experiences with that combination .

#302

Martin, I can imagine scored cylinders will not affect a stock imsb as much as an open ball bearing, which is more suceptible to debris. When it's hard to say in this case which is the culprit, at least that's a posibility.

Guys, could we refocus back on technical issues without bringing any personal attack or other business issues?

Guys, could we refocus back on technical issues without bringing any personal attack or other business issues?

It doesn't help to have aluminum dust inside your engine of course, but aluminum dust from scoring is not not big enough to damage IMS bearing in such a quick time frame.

#303

Rennlist Member

I won't lie. Yes, our process is expensive and there are cheaper ways to fix engines. It's a Porsche. And the process is proven with probably about 1500 engines sleeved to date with a 100% success rate and long term positive results.

#304

Rennlist Member

Charles,

I hoped you might have learned something by now. You should keep your less than intelligent comments to yourself. I stopped posting about your bearings publicly because I have no interest in it. It only gives me more work because I rebuild engines with LN bearings. I don't care about promoting my bearings, it's only a tiny % of my business. Unlike you, where you make your living selling those overpriced bearings which are not worth more than $100. Anyone can buy a $40 Japanese bearing and put SKF ceramic ***** in it. It's not a problem, anyone can do it. You have mentioned once that nobody can get those ceramic *****, but that is not true. SKF in Poland can bring me a whole truck of them, they have seen your ceramic ***** and said it's not an issue. If I wanted to sell them, I would have done it a long time ago. Your customers end up repairing their engines for 11,000 after your product fails. I have observed IMS sales recently and I can see a decline in sales for ball bearings, where roller bearings sales have gone up. Prepare yourself for even more failures, all the kits people installed will only get more miles on them and start failing more often. Same thing will happen to overprised nicasil resleeved blocks. I also know which company you send them to, if you keep commenting too much about me I will post the company publicly so people will save money and go directly to them.

You also made yourself look like an *** after you told you know who not to service my cylinder heads if he wants your business. The only outcome from that was him making less money. I have found another company in Europe which has really amazing prices and same quality products. You both came up with rnd engines trying to kill my business, but I guess you have little luck with that so far. Guys from SSF called me up trying to get my business and told me you can count the sales with one hand. I'm afraid you won't be able to compete with me unless you lower your prices by half

Good luck Charles, you're going to need it

-Martin Biernacki

I hoped you might have learned something by now. You should keep your less than intelligent comments to yourself. I stopped posting about your bearings publicly because I have no interest in it. It only gives me more work because I rebuild engines with LN bearings. I don't care about promoting my bearings, it's only a tiny % of my business. Unlike you, where you make your living selling those overpriced bearings which are not worth more than $100. Anyone can buy a $40 Japanese bearing and put SKF ceramic ***** in it. It's not a problem, anyone can do it. You have mentioned once that nobody can get those ceramic *****, but that is not true. SKF in Poland can bring me a whole truck of them, they have seen your ceramic ***** and said it's not an issue. If I wanted to sell them, I would have done it a long time ago. Your customers end up repairing their engines for 11,000 after your product fails. I have observed IMS sales recently and I can see a decline in sales for ball bearings, where roller bearings sales have gone up. Prepare yourself for even more failures, all the kits people installed will only get more miles on them and start failing more often. Same thing will happen to overprised nicasil resleeved blocks. I also know which company you send them to, if you keep commenting too much about me I will post the company publicly so people will save money and go directly to them.

You also made yourself look like an *** after you told you know who not to service my cylinder heads if he wants your business. The only outcome from that was him making less money. I have found another company in Europe which has really amazing prices and same quality products. You both came up with rnd engines trying to kill my business, but I guess you have little luck with that so far. Guys from SSF called me up trying to get my business and told me you can count the sales with one hand. I'm afraid you won't be able to compete with me unless you lower your prices by half

Good luck Charles, you're going to need it

-Martin Biernacki

Millennium Technologies has been our contractor since we started back in 2002. I don't hide that fact. Every block and up until recently, every set of aircooled cylinders came in a box from Millennium Technologies. I have a very long standing relationship with them and use them exclusively because they are the best. Yes, they will plate blocks directly and do so for other shops. That does not address cylinder strength issues and oversizes done without sleeving will fail if direct plating is applied.

And since you think I care if you publish where my bearings and the bearings for SSF and Pelican for that matter come from, CBR Bearing out of California does them. Again, a few strategically placed phone calls and you can find out who does them since he's the best in the country. It's no secret. If you ask for a quality ceramic bearing from Motion Industries or any other supplier like that, they buy them from him. Other competitors have called them for bearings and didn't want to pay what I pay for them, so they went elsewhere.

Cost of product has been discussed on other forums at great length. Wholesalers have their cut, shops have their cut, and I have overhead. I'm not a one man shop like I was ten years ago.

RND Engines was not created to compete with you. It wasn't even a consideration in my book. Porsche ceased offering replacement engines and the need for a superior replacement engine that would be readily available with a fast and fair core evaluation process (which Porsche lacked.) Yes, sales were slow to start but are moving along now that they have figured out how to sell engines. It's very different from other consumables these cars need and have their own set of logistics to deal with.

I never once said I would not do business with Wally if he continued to do work for you. He does stuff for me personally like for our Lemons car we run together but otherwise we are not reselling head work from any supplier. I also use Len Hoffman in GA as well for all our 914 heads we stock and sell. To be clear, Wally made that decision on his own not to do heads for you regardless of my opinion of you and how your carry out your own business. Wally can do work for anyone he likes. He is his own man, with his own business, and can make his own educated decisions. I respect Wally for the business he has created and seek his knowledge, expertise, and opinion as I value it greatly as a friend and colleague. I would ask you keep him out of this discussion as there was no reason to bring him into this.

This industry is small enough we can all co-exist happily regardless of what we think about each other. I for one have more important things to do than defend my credibility or that of the companies and people I deal with. How you choose to proceed is completely up to you.

#305

LA Sleeve offers cast sleeves, as does QSC (china) for the M96. It's in both their catalogs. We have fixed countless blocks having had both installed. Some we've even had to reject due to damage caused by installation of these sleeves.

I won't lie. Yes, our process is expensive and there are cheaper ways to fix engines. It's a Porsche. And the process is proven with probably about 1500 engines sleeved to date with a 100% success rate and long term positive results.

I won't lie. Yes, our process is expensive and there are cheaper ways to fix engines. It's a Porsche. And the process is proven with probably about 1500 engines sleeved to date with a 100% success rate and long term positive results.

There is no question you offer a superior product the issue is it's a street 996 not a 993 or earlier on a very flat price trajectory .

#306

Rennlist Member

I guess I don't understand what's unique about the Porsche block .Sleeving aluminum blocks has been done long before nickies .When you say countless was it because of bad machining or the sleeves themselves .

There is no question you offer a superior product the issue is it's a street 996 not a 993 or earlier on a very flat price trajectory .

There is no question you offer a superior product the issue is it's a street 996 not a 993 or earlier on a very flat price trajectory .

#307

Former Vendor

Every oem bearing has oil inside which gets in there through the shaft.

but aluminum dust from scoring is not not big enough to damage IMS bearing in such a quick time frame.

Its the tiny pieces that suspend in oil and do the biggest damage to ALL internally lubricated components.

I expected that Martin would know these fundamentals, since most enthusiast do.

Martin sure is concerned with what we do, and how we do it. Most like him are, as they are always trying to catch up.

#308

With scoring you have tiny aluminum pieces which are like dust. OEM bearing does get oil inside anyway, the rubber doesn't seal that well. Every oem bearing has oil inside which gets in there through the shaft. Rubber only protects it from large pieces of metal. Aluminum dust gets in there with oil all the time. I've seen it many times, I've also seen untouched roller bearing installed in motor with scoring problem.

It doesn't help to have aluminum dust inside your engine of course, but aluminum dust from scoring is not not big enough to damage IMS bearing in such a quick time frame.

It doesn't help to have aluminum dust inside your engine of course, but aluminum dust from scoring is not not big enough to damage IMS bearing in such a quick time frame.

I can definitely see the logic in your explanation. Fine debris is not good for sure but I think how much it can make the other parts fail is the critical question. Whether the oil filter bypass valve was tripped is another big factor. It may lead to much larger debris being circulated.

#309

No, it "gets there" THROUGH toe OEM bearing! Thats part of Stage II IMSB failure. The shaft is otherwise fully sealed.

Ha!

Its the tiny pieces that suspend in oil and do the biggest damage to ALL internally lubricated components.

I expected that Martin would know these fundamentals, since most enthusiast do.

Martin sure is concerned with what we do, and how we do it. Most like him are, as they are always trying to catch up.

Ha!

Its the tiny pieces that suspend in oil and do the biggest damage to ALL internally lubricated components.

I expected that Martin would know these fundamentals, since most enthusiast do.

Martin sure is concerned with what we do, and how we do it. Most like him are, as they are always trying to catch up.

Yes, you're right, I meant that oil gets into the shaft through oem bearing, not through the shaft. Everybody knows it, it was just a wrong expression on my end which created misunderstanding.

Since you claim the dust is supposed to make the biggest damage, how would you explain the fact that every single engine with scoring problem and oem bearing I take apart, the bearing is in perfect condition every time. Even in extreme scoring cases. Other engines with LN bearing and no scoring problem already have first signs of being loose. Inner and outer races are beginning to wear. If you would like to see pictures just let me know.

I mentioned before that if someone would like to solve ims issue they should get your ims solution or roller bearing. Especially in case of single row bearings. We both know single row ln bearings fail, dual row not so much. If you both admitted this design is weak we wouldn't have this conversation. Customer always hears it's either wrong installation, misalignment, scoring or any other internal issue which supposedly led to ims failure.

#310

I also agree MBM and LN/F6/RND are not serving the same market segment. On older and higher mileage models which are under 20k even with a running engine, I think most are looking for a $10-15k solution with reasonable reliability (say another 100k miles on the engine so the car will be like 200k total). The challenge though is how to achieve that within budget and yet still make the engine robust enough. Whoever find that formula will be very successful. On the other hand, if the cheaper rebuilt engines keep blowing up, ppl will also notice. So yea, no argument is necessary since the market will play out and speak for itself in the long run.

Of course there are plenty of people who want the best in their cars and money is no object. It's evident that F6 is booked for year+.

Of course there are plenty of people who want the best in their cars and money is no object. It's evident that F6 is booked for year+.

Martin, remember, you started this, yet again. Post the company that does your sleeving or anyone elses sleeving, I don't care. It's very easy to find who else sleeves M96 engines. Google is a wonderful tool. I just posted who makes the sleeves for the M96 in fact. It's no secret.

Millennium Technologies has been our contractor since we started back in 2002. I don't hide that fact. Every block and up until recently, every set of aircooled cylinders came in a box from Millennium Technologies. I have a very long standing relationship with them and use them exclusively because they are the best. Yes, they will plate blocks directly and do so for other shops. That does not address cylinder strength issues and oversizes done without sleeving will fail if direct plating is applied.

And since you think I care if you publish where my bearings and the bearings for SSF and Pelican for that matter come from, CBR Bearing out of California does them. Again, a few strategically placed phone calls and you can find out who does them since he's the best in the country. It's no secret. If you ask for a quality ceramic bearing from Motion Industries or any other supplier like that, they buy them from him. Other competitors have called them for bearings and didn't want to pay what I pay for them, so they went elsewhere.

Cost of product has been discussed on other forums at great length. Wholesalers have their cut, shops have their cut, and I have overhead. I'm not a one man shop like I was ten years ago.

RND Engines was not created to compete with you. It wasn't even a consideration in my book. Porsche ceased offering replacement engines and the need for a superior replacement engine that would be readily available with a fast and fair core evaluation process (which Porsche lacked.) Yes, sales were slow to start but are moving along now that they have figured out how to sell engines. It's very different from other consumables these cars need and have their own set of logistics to deal with.

I never once said I would not do business with Wally if he continued to do work for you. He does stuff for me personally like for our Lemons car we run together but otherwise we are not reselling head work from any supplier. I also use Len Hoffman in GA as well for all our 914 heads we stock and sell. To be clear, Wally made that decision on his own not to do heads for you regardless of my opinion of you and how your carry out your own business. Wally can do work for anyone he likes. He is his own man, with his own business, and can make his own educated decisions. I respect Wally for the business he has created and seek his knowledge, expertise, and opinion as I value it greatly as a friend and colleague. I would ask you keep him out of this discussion as there was no reason to bring him into this.

This industry is small enough we can all co-exist happily regardless of what we think about each other. I for one have more important things to do than defend my credibility or that of the companies and people I deal with. How you choose to proceed is completely up to you.

Millennium Technologies has been our contractor since we started back in 2002. I don't hide that fact. Every block and up until recently, every set of aircooled cylinders came in a box from Millennium Technologies. I have a very long standing relationship with them and use them exclusively because they are the best. Yes, they will plate blocks directly and do so for other shops. That does not address cylinder strength issues and oversizes done without sleeving will fail if direct plating is applied.

And since you think I care if you publish where my bearings and the bearings for SSF and Pelican for that matter come from, CBR Bearing out of California does them. Again, a few strategically placed phone calls and you can find out who does them since he's the best in the country. It's no secret. If you ask for a quality ceramic bearing from Motion Industries or any other supplier like that, they buy them from him. Other competitors have called them for bearings and didn't want to pay what I pay for them, so they went elsewhere.

Cost of product has been discussed on other forums at great length. Wholesalers have their cut, shops have their cut, and I have overhead. I'm not a one man shop like I was ten years ago.

RND Engines was not created to compete with you. It wasn't even a consideration in my book. Porsche ceased offering replacement engines and the need for a superior replacement engine that would be readily available with a fast and fair core evaluation process (which Porsche lacked.) Yes, sales were slow to start but are moving along now that they have figured out how to sell engines. It's very different from other consumables these cars need and have their own set of logistics to deal with.

I never once said I would not do business with Wally if he continued to do work for you. He does stuff for me personally like for our Lemons car we run together but otherwise we are not reselling head work from any supplier. I also use Len Hoffman in GA as well for all our 914 heads we stock and sell. To be clear, Wally made that decision on his own not to do heads for you regardless of my opinion of you and how your carry out your own business. Wally can do work for anyone he likes. He is his own man, with his own business, and can make his own educated decisions. I respect Wally for the business he has created and seek his knowledge, expertise, and opinion as I value it greatly as a friend and colleague. I would ask you keep him out of this discussion as there was no reason to bring him into this.

This industry is small enough we can all co-exist happily regardless of what we think about each other. I for one have more important things to do than defend my credibility or that of the companies and people I deal with. How you choose to proceed is completely up to you.

#311

After-market intermediate shaft bearings are snake oil. Hopefully anyone wading thru this abortion of a thread thus far would come to that realization on his or her own. Normally I don't post on this forum anymore ... after a thread like this it should be obvious why. The people that make money selling these after-market monkey parts flog Rennlist relentlessly.

But when you start bashing the guy based on his English? Poor form, gentlemen, poor form.

But when you start bashing the guy based on his English? Poor form, gentlemen, poor form.

#312

LA Sleeve offers cast sleeves, as does QSC (china) for the M96. It's in both their catalogs. We have fixed countless blocks having had both installed. Some we've even had to reject due to damage caused by installation of these sleeves.

I won't lie. Yes, our process is expensive and there are cheaper ways to fix engines. It's a Porsche. And the process is proven with probably about 1500 engines sleeved to date with a 100% success rate and long term positive results.

I won't lie. Yes, our process is expensive and there are cheaper ways to fix engines. It's a Porsche. And the process is proven with probably about 1500 engines sleeved to date with a 100% success rate and long term positive results.

This is why I only use one place in Poland for resleeving. They use steel sleeve technology, which has worked for me for all these years. I have seen many resleeved blocks here in US, and none of them were done right. I can agree with you for once

Our partner in Poland rents his Porsches for track racing. All his engines have steel cylinders. When he takes them apart to refresh the motors every now and then, steel sleeves look like new every time.

This company also resleeves blocks and rebuilds engines for customers in Russia, where people drive their cars all year long in extreme conditions and temperatures. This technology solves scoring and d chunk issues for good.

Europeans used to resleeve their blocks with nicasil, they drive their cars all year long in cold temps and put a lot more miles than American owners. Nickes would peel after long wear and tear, and eventually would lead to engine damage. This is why every knowledgeable shop in Europe uses steel sleeve technology. Just look on German Ebay and you will see how many shops advertise steel technology.

I'm afraid that after long wear and tear same thing will happen to your nickes what happened with your single row bearings. The more you drive it the more it fails.

What I'm offering my customers is a product that will not break no matter how many miles they drive and in which conditions.

#313

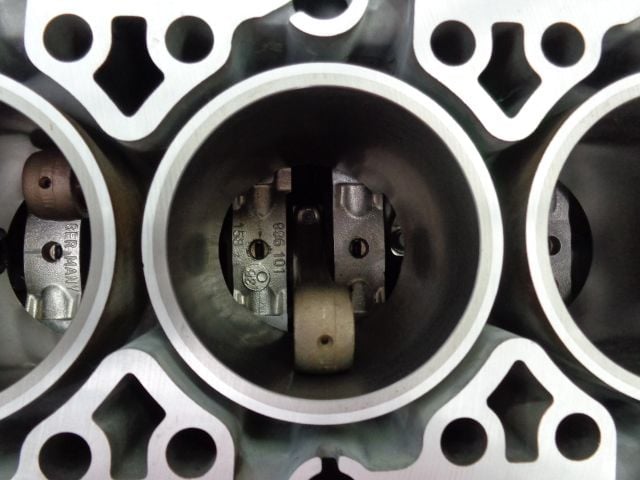

Martin, using Cringely's engine as an example with photos here https://rennlist.com/forums/996-foru...l#post12466819 Similar scoring is found on both the load bearing and non-load bearing side on ALL 6 cylinders with scoring worse on the ones closer to the IMSB end.

What will it cost to fix the cylinders? The skirt coating on the stock pistons are also pitted a bit, are new pistons needed too? Thanks.

What will it cost to fix the cylinders? The skirt coating on the stock pistons are also pitted a bit, are new pistons needed too? Thanks.

#314

Martin, using Cringely's engine as an example with photos here https://rennlist.com/forums/996-foru...l#post12466819 Similar scoring is found on both the load bearing and non-load bearing side on ALL 6 cylinders with scoring worse on the ones closer to the IMSB end.

What will it cost to fix the cylinders? The skirt coating on the stock pistons are also pitted a bit, are new pistons needed too? Thanks.

What will it cost to fix the cylinders? The skirt coating on the stock pistons are also pitted a bit, are new pistons needed too? Thanks.

After looking at these pics, I'm sure scoring has not caused this imsb to fail. Typical scoring is usually on passenger side on cylinders 4-6 on upper side of cylinders. It's caused by not enough oil getting all the way up there because crank shaft turns to the right side (clockwise) lubricating better on driver side cylinders 1-3. It's caused by low oil level, not changing oil often enough, low temps, too high temp (pistons expand). Every single engine has scoring on cylinders 4-6 because of that. Cylinders 1-3 are usually in good condition if you have a scoring problem. Even if they're scored in the upper part, the lower part is mostly untouched.

As I mentioned before, even in extreme scoring cases on top of pistons it wouldn't cause imsb damage.

These pics clearly show that these scratches (which I wouldn't call scoring) were caused by something getting inside the engine. In my opinion the bearing started to shed metal and little pieces of metal shavings from races got into pistons and caused these scratches. Bearing must have been loose and engine still ran until bearing finally broke and engine stopped. It's exactly the same when oem bearing failure happens.

To me it's clear that another LN bearing caused engine failure. All you need is a little imagination and logical thinking to understand the series of events. Some people believe in different things and different "Gods", there is nothing I can do about it...It's not the first time and certainly not the last time LN bearing failed.

If you say that there is still coating on pistons but it's scratched, it indicates pieces of ims getting inside there and causing the damage. Usually, in case of real scoring the coating is worn out and aluminum grinds against aluminum. The scratches in this motor were caused by debris from IMSB getting inside. Your pistons are scratched more on the bottom because there is more oil with debris in this area. I see it all the time with oem or ln bearings, cylinders get scratched the same way as yours.

I always think logically and tell the truth, I don't believe in other's theories. You said it's damaged more by IMSB, it would make sense since the debris from IMS got there first and made the most damage.

As far as the resleeving cost, I have attached sample pics, and if you're interested in doing both sides, all 6 cylinders cost is $3200, shipping to Poland included. UPS will pick up the package and drop it off when it's ready.

A set of specially fitted piston rings is included in this cost.

#315

Rennlist Member

This is why I only use one place in Poland for resleeving. They use steel sleeve technology, which has worked for me for all these years. I have seen many resleeved blocks here in US, and none of them were done right. I can agree with you for once

Our partner in Poland rents his Porsches for track racing. All his engines have steel cylinders. When he takes them apart to refresh the motors every now and then, steel sleeves look like new every time.

This company also resleeves blocks and rebuilds engines for customers in Russia, where people drive their cars all year long in extreme conditions and temperatures. This technology solves scoring and d chunk issues for good.

Europeans used to resleeve their blocks with nicasil, they drive their cars all year long in cold temps and put a lot more miles than American owners. Nickes would peel after long wear and tear, and eventually would lead to engine damage. This is why every knowledgeable shop in Europe uses steel sleeve technology. Just look on German Ebay and you will see how many shops advertise steel technology.

I'm afraid that after long wear and tear same thing will happen to your nickes what happened with your single row bearings. The more you drive it the more it fails.

What I'm offering my customers is a product that will not break no matter how many miles they drive and in which conditions.

Our partner in Poland rents his Porsches for track racing. All his engines have steel cylinders. When he takes them apart to refresh the motors every now and then, steel sleeves look like new every time.

This company also resleeves blocks and rebuilds engines for customers in Russia, where people drive their cars all year long in extreme conditions and temperatures. This technology solves scoring and d chunk issues for good.

Europeans used to resleeve their blocks with nicasil, they drive their cars all year long in cold temps and put a lot more miles than American owners. Nickes would peel after long wear and tear, and eventually would lead to engine damage. This is why every knowledgeable shop in Europe uses steel sleeve technology. Just look on German Ebay and you will see how many shops advertise steel technology.

I'm afraid that after long wear and tear same thing will happen to your nickes what happened with your single row bearings. The more you drive it the more it fails.

What I'm offering my customers is a product that will not break no matter how many miles they drive and in which conditions.

Strict testing is done to control adhesion issues and the platers give a lifetime warranty on adhesion. Nikasil has never been an issue when done right and we've never had a single adhesion problem ever. Saying there will be as more people drive their cars is ludicrous.

Our engines have been raced and there are cars out there with over 100,000 miles on our cylinders, both aircooled and watercooled. The technology is proven. I challenge you to find a single forum thread about a problem with any of our cylinders whatsoever. You won't find one because they don't exist.

You'll know you've built enough engines or sold enough ims bearings once you have a few failures. It's a matter of numbers. It's impossible to prevent 100% of failures. It's a mechanical system and I have made this point thoroughly in past discussions with you and others. No one is trying to hide anything here.