Cage time for the 928

#16

Drifting

Looks pretty good so far, but as you are doing this just take a second to analyze how the loads are transferred between the individual tubes (and how, in turn, they transfer loads to the chassis) to think about where your junctions should be and what angles are preferable. There is no "right" answer, but don't just blindly follow others' suggestions--think about what you are doing, take in everyone's suggestions, and decide on what you deem is the best solution.

You may want to check the rules on this: I have since forgotten, but I think you want the rear kickbacks to meet the main hoop at the node where the halo meets the main hoop. Either way, I wouldn't want two points that close to each other--but not directly across from each other--with all of the welding going on. I would also say move the kickbacks to the area just beside the shock towers, on the top of that rear crossmember instead of the front face.

Just read Kibort's responses. I should have consulted him when I built our cage... shucks! Simply put, Kibort knows more than anyone else on the subject of roll cages, so you might as well disregard what I and others suggest.

You may want to check the rules on this: I have since forgotten, but I think you want the rear kickbacks to meet the main hoop at the node where the halo meets the main hoop. Either way, I wouldn't want two points that close to each other--but not directly across from each other--with all of the welding going on. I would also say move the kickbacks to the area just beside the shock towers, on the top of that rear crossmember instead of the front face.

Just read Kibort's responses. I should have consulted him when I built our cage... shucks! Simply put, Kibort knows more than anyone else on the subject of roll cages, so you might as well disregard what I and others suggest.

#17

Rennlist Member

Mark, Ill take that as a complement. (you knuckelhead)

LOOK, i love that build of yours! That fender work was GENIUS! I will do that mod to add to the simiar idea I had originally. The entire car is beautiful! really. just a few things you could have done, by your own admission, that I could have helped you watch out for.

1. that vertical bar in the driver area. effects vision, dangerous to get out in a crash. forget about gettting out in your garage, try on fire and with things bent up a little!

also, you admit it, with a halo seat, you wont be able to exit the car, but you dont have one, but everyone is going that direction, so why have it?

2. that knee bar. not needed, the stock chassis a bar adaquate, but you could replace the stock bar and put in a larger one. not required by most sanctioning bodies. but , i wouldnt want a bar down low to break my legs in an accident

Look, you think I built my cage?? I have been racing this 928 more than anyone over the last 10 years. Ive built 5 race cars all with different cages built by different shops, and RACED them and even had very serious impacts with 2 of them.

Again, my advice comes from very skilled welders and professional race car builders, that build competitive cars for SCCA world challenge, Grand AM , BMWCCA, etc. Impact Engineering does fantastic work. the only input I put down in the cage was changes made by me RACING the car and seeing things that made it uncomfortable, more convenient, or safer.

most of the cage builders, maybe you included, are used to working with flim flam BMWs and have to over build the cage to stiffen the chassis. all my ideas came from existing designs and my own cage's drawbacks.

Knowing what we know about the chasssis and its stiffness and strength, tells us many of the crazy x bars are not required. Its just extra weight.

I agree, you want to hit the attachement poins to the strongest parts of the car. the front door sills up to the front ABS computer area, with big plates to spread the load. rear attachements can be on top or on the side of that cross memeber. remember you said it, you have to understand the load forces. a large plate attached to that rear shock tower, is fine, on top or on the front side.

The side bars are most critical, for protection but too many side bars, and down bars could be very dangerous. the 928 is a tough car to get in an out of, and you dont want to burn to death in a fire, because you cant get out, either fast enough or at all in a roll over or side impact.

I think the cage Impact Engneering did on my car is nice, functional and safe.

there is nothing wrong with copying what has worked for someone in the sport.

when you see a pro company , that builds race cars for a living, and makes a functinoal cage, there is nothing wrong with copying it and making subtle changes to fit your individual needs. This design has a halo bar now. If we discussed that, i would have voted not to have one, to avoild the discussion with SCCA scrutiners, about why it should be approved as being legal. It probalby wont be an issue, but it might depend on who checks out your car.

I know you love me for saving you all that weight on the wing mount design and re-design and also the fender idea. (I think) >>>> https://rennlist.com/forums/6250686-post97.html

LOOK, i love that build of yours! That fender work was GENIUS! I will do that mod to add to the simiar idea I had originally. The entire car is beautiful! really. just a few things you could have done, by your own admission, that I could have helped you watch out for.

1. that vertical bar in the driver area. effects vision, dangerous to get out in a crash. forget about gettting out in your garage, try on fire and with things bent up a little!

also, you admit it, with a halo seat, you wont be able to exit the car, but you dont have one, but everyone is going that direction, so why have it?

2. that knee bar. not needed, the stock chassis a bar adaquate, but you could replace the stock bar and put in a larger one. not required by most sanctioning bodies. but , i wouldnt want a bar down low to break my legs in an accident

Look, you think I built my cage?? I have been racing this 928 more than anyone over the last 10 years. Ive built 5 race cars all with different cages built by different shops, and RACED them and even had very serious impacts with 2 of them.

Again, my advice comes from very skilled welders and professional race car builders, that build competitive cars for SCCA world challenge, Grand AM , BMWCCA, etc. Impact Engineering does fantastic work. the only input I put down in the cage was changes made by me RACING the car and seeing things that made it uncomfortable, more convenient, or safer.

most of the cage builders, maybe you included, are used to working with flim flam BMWs and have to over build the cage to stiffen the chassis. all my ideas came from existing designs and my own cage's drawbacks.

Knowing what we know about the chasssis and its stiffness and strength, tells us many of the crazy x bars are not required. Its just extra weight.

I agree, you want to hit the attachement poins to the strongest parts of the car. the front door sills up to the front ABS computer area, with big plates to spread the load. rear attachements can be on top or on the side of that cross memeber. remember you said it, you have to understand the load forces. a large plate attached to that rear shock tower, is fine, on top or on the front side.

The side bars are most critical, for protection but too many side bars, and down bars could be very dangerous. the 928 is a tough car to get in an out of, and you dont want to burn to death in a fire, because you cant get out, either fast enough or at all in a roll over or side impact.

I think the cage Impact Engneering did on my car is nice, functional and safe.

there is nothing wrong with copying what has worked for someone in the sport.

when you see a pro company , that builds race cars for a living, and makes a functinoal cage, there is nothing wrong with copying it and making subtle changes to fit your individual needs. This design has a halo bar now. If we discussed that, i would have voted not to have one, to avoild the discussion with SCCA scrutiners, about why it should be approved as being legal. It probalby wont be an issue, but it might depend on who checks out your car.

I know you love me for saving you all that weight on the wing mount design and re-design and also the fender idea. (I think) >>>> https://rennlist.com/forums/6250686-post97.html

Looks pretty good so far, but as you are doing this just take a second to analyze how the loads are transferred between the individual tubes (and how, in turn, they transfer loads to the chassis) to think about where your junctions should be and what angles are preferable. There is no "right" answer, but don't just blindly follow others' suggestions--think about what you are doing, take in everyone's suggestions, and decide on what you deem is the best solution.

You may want to check the rules on this: I have since forgotten, but I think you want the rear kickbacks to meet the main hoop at the node where the halo meets the main hoop. Either way, I wouldn't want two points that close to each other--but not directly across from each other--with all of the welding going on. I would also say move the kickbacks to the area just beside the shock towers, on the top of that rear crossmember instead of the front face.

Just read Kibort's responses. I should have consulted him when I built our cage... shucks! Simply put, Kibort knows more than anyone else on the subject of roll cages, so you might as well disregard what I and others suggest.

You may want to check the rules on this: I have since forgotten, but I think you want the rear kickbacks to meet the main hoop at the node where the halo meets the main hoop. Either way, I wouldn't want two points that close to each other--but not directly across from each other--with all of the welding going on. I would also say move the kickbacks to the area just beside the shock towers, on the top of that rear crossmember instead of the front face.

Just read Kibort's responses. I should have consulted him when I built our cage... shucks! Simply put, Kibort knows more than anyone else on the subject of roll cages, so you might as well disregard what I and others suggest.

Last edited by mark kibort; 05-16-2011 at 03:40 PM.

#18

Rennlist Member

pretty nice, but a few too many bars in places not needed a full x in the rear downbars is a little much on a 928. also , dont think the matter cage up front is needed . there are not that many cars that are that strong in that area of the chassis. welding the bar to the A pillar would be a good adder.

Check out www.cagethis.com in iis archives he has pic of a sweet cage in a 928.

#19

Three Wheelin'

Thread Starter

Wow lots of info to remember here.... Im bored at work so sorry if this is an obscenely long post.

hence why I posted this

thats is an amazing piece of design but seems a bit overkill in a car with less than 300hp... and yes I know that overkill and roll cage shouldnt be used in the same sentence, but even cup cars dont have 6 different overhead bars

anyway...

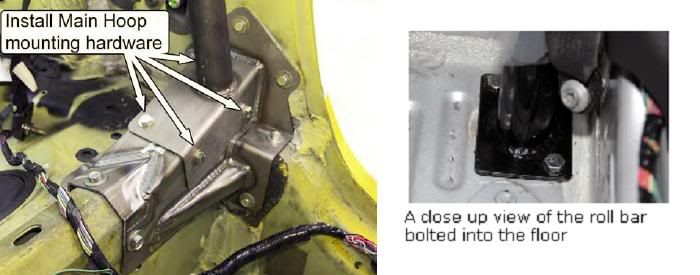

The front bars will be welded to the floor and the plate will be welded to the sidebar, plus I can weld some gussets there too because Im definitely not going to need all 50 that came with the kit. Both Kibort's and Benton's cars look like they have a similar setup, where the bar isnt directly attached to the sill but the reinforcement plate is. Plus I do plan on welding the front bars to the a-pillar for a little extra support at less than 2lbs of weight.

I dont plan to use a downbar near the a-pillar because even without a halo seat, theres not a hope hell Ill be able to get in and out in less than a day. Although I will probably end up throwing a small downbar from the roof loop to the main hoop in an effort to help avoid spinal crunchies

The kit came with 2 nascar door bars with a crapload of small support bars so that should cover the sides fairly well once I gut the doors and remove the last pieces of glass on the car.

I wont be using an extra x-brace between the rear kickbacks mainly because they were not included in the kit and I dont want to lose the ability to carry passengers in the back seats

are you 100% some sort of frontal cross bar is not required for SCCA? I could have sworn it was...

I was not aware of this, how close do you reckon they need to be? The tubing might be a bit short now that its already cut.

My thoughts exactly, although it is slightly further from the actual mounting point, it wont make it substantially stiffer by any means. Also the majority of the weight will be more centered and less spread out since my hybrid 928 already as a 911esque rear weight bias... not like thats really going to make a difference but every little bit helps.

oh man, I'm not going anywhere near that one...

take in everyone's suggestions, and decide on what you deem is the best solution.

thats is an amazing piece of design but seems a bit overkill in a car with less than 300hp... and yes I know that overkill and roll cage shouldnt be used in the same sentence, but even cup cars dont have 6 different overhead bars

anyway...

The front bars will be welded to the floor and the plate will be welded to the sidebar, plus I can weld some gussets there too because Im definitely not going to need all 50 that came with the kit. Both Kibort's and Benton's cars look like they have a similar setup, where the bar isnt directly attached to the sill but the reinforcement plate is. Plus I do plan on welding the front bars to the a-pillar for a little extra support at less than 2lbs of weight.

I dont plan to use a downbar near the a-pillar because even without a halo seat, theres not a hope hell Ill be able to get in and out in less than a day. Although I will probably end up throwing a small downbar from the roof loop to the main hoop in an effort to help avoid spinal crunchies

The kit came with 2 nascar door bars with a crapload of small support bars so that should cover the sides fairly well once I gut the doors and remove the last pieces of glass on the car.

I wont be using an extra x-brace between the rear kickbacks mainly because they were not included in the kit and I dont want to lose the ability to carry passengers in the back seats

that knee bar. not needed, the stock chassis a bar adaquate, but you could replace the stock bar and put in a larger one. not required by most sanctioning bodies

I think you want the rear kickbacks to meet the main hoop at the node where the halo meets the main hoop. Either way, I wouldn't want two points that close to each other--but not directly across from each other--with all of the welding going on.

rear attachements can be on top or on the side of that cross memeber. remember you said it, you have to understand the load forces. a large plate attached to that rear shock tower, is fine, on top or on the front side.

Kibort knows more than anyone else on the subject of roll cages, so you might as well disregard what I and others suggest.

#20

Administrator - "Tyson"

Lifetime Rennlist

Member

Lifetime Rennlist

Member

Some very good info on caging a 928 on Mike Simard's website:

http://www.simardracing.com/CarBuildBlog.html

http://www.simardracing.com/CarBuildBlog.html

#23

Rennlist Member

see my inserts.

thats is an amazing piece of design but seems a bit overkill in a car with less than 300hp... and yes I know that overkill and roll cage shouldnt be used in the same sentence, but even cup cars dont have 6 different overhead bars

>>>>>>>>>>>yes way overkill! and Lots of weight!

anyway...

The front bars will be welded to the floor and the plate will be welded to the sidebar, plus I can weld some gussets there too because Im definitely not going to need all 50 that came with the kit. Both Kibort's and Benton's cars look like they have a similar setup, where the bar isnt directly attached to the sill but the reinforcement plate is. Plus I do plan on welding the front bars to the a-pillar for a little extra support at less than 2lbs of weight.

>>>>>just a plate along part of the distance of the a pillar will do. not really needed. again, the 928 is monster stiff in the roof area.

I dont plan to use a downbar near the a-pillar because even without a halo seat, theres not a hope hell Ill be able to get in and out in less than a day. Although I will probably end up throwing a small downbar from the roof loop to the main hoop in an effort to help avoid spinal crunchies

>>>>>that was my only critism with Mark's cage. really not needed and could impede egress and ingress. plus, in a crash, stuff gets bent. you dont want to be in "cage jail" when a fire breaks out! or you have broken ribs or a shoulder and the "guys" cant get you out! Ive seen this happen before and its not pretty!

The kit came with 2 nascar door bars with a crapload of small support bars so that should cover the sides fairly well once I gut the doors and remove the last pieces of glass on the car.

I wont be using an extra x-brace between the rear kickbacks mainly because they were not included in the kit and I dont want to lose the ability to carry passengers in the back seats

>>>>>>>>funny! i dont go all the way to the shock towers because you can get a real flush mount and weld to a plate that the rear kickback bars weld to. either way, the forces are at angles.

are you 100% some sort of frontal cross bar is not required for SCCA? I could have sworn it was...

>>>>>>>>>>>>the stock cross bar will suffice for the rules and be plenty safe.

I was not aware of this, how close do you reckon they need to be? The tubing might be a bit short now that its already cut.

>>>>>>>>>more of a preference, than detailed in the rules. where you have them now looks fine.

My thoughts exactly, although it is slightly further from the actual mounting point, it wont make it substantially stiffer by any means. Also the majority of the weight will be more centered and less spread out since my hybrid 928 already as a 911esque rear weight bias... not like thats really going to make a difference but every little bit helps.

<<<<<<<dont think that is a big deal by any stretch.

oh man, I'm not going anywhere near that one.>>>>>>> just ask Mark of the ideas ive given him for rippign out that way over built welded plate to hold his wing a few years ago, and the idea for the fender "Pull out" design which perfected to a degree and creativity never seen before here on the list! very very nice. So, if I offer some advice on the cage, im sure he is listening. the good news, those down bars can be cut out in a few minutes!

very very nice. So, if I offer some advice on the cage, im sure he is listening. the good news, those down bars can be cut out in a few minutes!  ..

..

>>>>>>>>>>>yes way overkill! and Lots of weight!

anyway...

The front bars will be welded to the floor and the plate will be welded to the sidebar, plus I can weld some gussets there too because Im definitely not going to need all 50 that came with the kit. Both Kibort's and Benton's cars look like they have a similar setup, where the bar isnt directly attached to the sill but the reinforcement plate is. Plus I do plan on welding the front bars to the a-pillar for a little extra support at less than 2lbs of weight.

>>>>>just a plate along part of the distance of the a pillar will do. not really needed. again, the 928 is monster stiff in the roof area.

I dont plan to use a downbar near the a-pillar because even without a halo seat, theres not a hope hell Ill be able to get in and out in less than a day. Although I will probably end up throwing a small downbar from the roof loop to the main hoop in an effort to help avoid spinal crunchies

>>>>>that was my only critism with Mark's cage. really not needed and could impede egress and ingress. plus, in a crash, stuff gets bent. you dont want to be in "cage jail" when a fire breaks out! or you have broken ribs or a shoulder and the "guys" cant get you out! Ive seen this happen before and its not pretty!

The kit came with 2 nascar door bars with a crapload of small support bars so that should cover the sides fairly well once I gut the doors and remove the last pieces of glass on the car.

I wont be using an extra x-brace between the rear kickbacks mainly because they were not included in the kit and I dont want to lose the ability to carry passengers in the back seats

>>>>>>>>funny! i dont go all the way to the shock towers because you can get a real flush mount and weld to a plate that the rear kickback bars weld to. either way, the forces are at angles.

are you 100% some sort of frontal cross bar is not required for SCCA? I could have sworn it was...

>>>>>>>>>>>>the stock cross bar will suffice for the rules and be plenty safe.

I was not aware of this, how close do you reckon they need to be? The tubing might be a bit short now that its already cut.

>>>>>>>>>more of a preference, than detailed in the rules. where you have them now looks fine.

My thoughts exactly, although it is slightly further from the actual mounting point, it wont make it substantially stiffer by any means. Also the majority of the weight will be more centered and less spread out since my hybrid 928 already as a 911esque rear weight bias... not like thats really going to make a difference but every little bit helps.

<<<<<<<dont think that is a big deal by any stretch.

oh man, I'm not going anywhere near that one.>>>>>>> just ask Mark of the ideas ive given him for rippign out that way over built welded plate to hold his wing a few years ago, and the idea for the fender "Pull out" design which perfected to a degree and creativity never seen before here on the list!

very very nice. So, if I offer some advice on the cage, im sure he is listening. the good news, those down bars can be cut out in a few minutes!

very very nice. So, if I offer some advice on the cage, im sure he is listening. the good news, those down bars can be cut out in a few minutes!  ..

..

#24

Please don't run the front bars down to the floor, run them to the sills. You'll punch right through the floor even if you put a pretty big plate down there. It's easy to move the bars now and it's far stronger than the floor. You don't want to wind up like that guy in the mustang ;-) See the cage through that floor?:

-Previous 928 racer ;-)

-Previous 928 racer ;-)

#25

Three Wheelin'

Thread Starter

Some very good info on caging a 928 on Mike Simard's website:

http://www.simardracing.com/CarBuildBlog.html

http://www.simardracing.com/CarBuildBlog.html

That is one hell of a build, 14" baer brakes, custom a-arms, and motec computers... a hefty investment of time and $ by anyone's standards

Please don't run the front bars down to the floor, run them to the sills. You'll punch right through the floor even if you put a pretty big plate down there. It's easy to move the bars now and it's far stronger than the floor. You don't want to wind up like that guy in the mustang ;-) See the cage through that floor?

Thanks for the advice but Ill take my chances seeing as many other 928 racers have used this design and none of them have been squished to death. Example below:

Please tell me you aren't planning on welding the cage with a flux core MIG welded...

Those were just tack welds to keep the bars in place until I can borrow a friends MIG welder... one of the many disadvantages of having a garage the size of a toaster

see my inserts.

I'll keep this thread updated as progress goes on but it might be a few days as this damn rain is supposed to go on all week

Last edited by ubercooper; 05-17-2011 at 09:10 PM.

#26

Rennlist Member

that is REALLY ugly! knuckelhead cage or even roll bar design.

Please don't run the front bars down to the floor, run them to the sills. You'll punch right through the floor even if you put a pretty big plate down there. It's easy to move the bars now and it's far stronger than the floor. You don't want to wind up like that guy in the mustang ;-) See the cage through that floor?:

-Previous 928 racer ;-)

-Previous 928 racer ;-)

#27

Three Wheelin'

Thread Starter

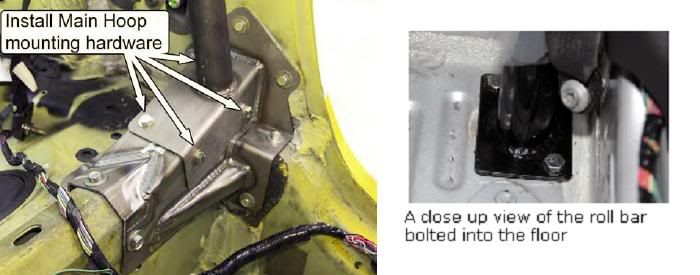

Heres a picture of the proper bolt in roll bar mount vs the autopower mount which was used in the mustang... also that car is about 800lbs heavier than our welterweight 928s.

4x3" with 2 bolts < 8x6" with MIG welds

4x3" with 2 bolts < 8x6" with MIG welds

#28

Three Wheelin'

Thread Starter

Another day and its almost done, all that's left are the door bars and it'll be ready to be welded up.

...but Ive ran into another problem. Since I didnt want to risk a slow escape and crushing ankles should anything happen, I opted to put the front cross bar above the steering wheel. It looks good and fit perfectly with no modifications, however it is now blocking where the gauges would mount to the steering column. Has anyone remounted their gauge cluster on a 928? If so is there a preferred method, or should I just remove it and re-tack it below the wheel?

Here are some pics:

...but Ive ran into another problem. Since I didnt want to risk a slow escape and crushing ankles should anything happen, I opted to put the front cross bar above the steering wheel. It looks good and fit perfectly with no modifications, however it is now blocking where the gauges would mount to the steering column. Has anyone remounted their gauge cluster on a 928? If so is there a preferred method, or should I just remove it and re-tack it below the wheel?

Here are some pics:

#29

Rennlist Member

cut that bar out!!! do it now!!!!!!

you dont need it, if you are concerned with lateral stifness, tie you cage into the existing coss bar and further increase stiffness by some plates welded from the a pillars to the cage a pillar.

you made a GOOD decision to not use the ankle buster bar (or knee buster)

this is a 928, not a miata. want to see the shape my car is in from a 100mph crash into the wall when I got hit by the honda causing the wreck?? i think pictures of the damaged cage is above in the pics .

cage looks great by the way!

you dont need it, if you are concerned with lateral stifness, tie you cage into the existing coss bar and further increase stiffness by some plates welded from the a pillars to the cage a pillar.

you made a GOOD decision to not use the ankle buster bar (or knee buster)

this is a 928, not a miata. want to see the shape my car is in from a 100mph crash into the wall when I got hit by the honda causing the wreck?? i think pictures of the damaged cage is above in the pics .

cage looks great by the way!

#30

Three Wheelin'

Thread Starter

you dont need it, if you are concerned with lateral stifness, tie you cage into the existing coss bar and further increase stiffness by some plates welded from the a pillars to the cage a pillar.

want to see the shape my car is in from a 100mph crash into the wall when I got hit by the honda causing the wreck??

Last edited by ubercooper; 05-23-2011 at 01:29 AM.