Air Pump Powered Crankvent

#1

Inventor

Rennlist Member

Rennlist Member

Thread Starter

Vacuum measured at the dipstick tube while parked:

KILOPASCAL

1 @ 850

4 @ 3000

8 @ 5600

Bounces 8-10+ at 6000

From what I've read, 15" of mercury vacuum is the max safe level for performance. This gives a maximum of 2.5" - 3", so it's really for just for venting, but only costs <$30 in parts (already have the air pump anyway).

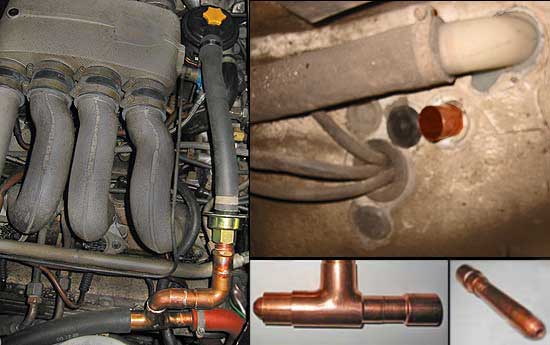

Left: Vacuum generator, one way valve keeps vacuum stable.

Upper Right: Outlet in fender used existing hole.

Bottom Right: Air jet. 3/16" hole drilled in 1/2" stub out.

Notes:

My air pump (with possibly 110K miles) makes a maximum of about 10 PSI air pressure when plugged.

Makes a puffing noise at idle, similar to an exhaust manifold leak.

No stinky vapors while the heater is on!

*Original Thread*

~thread~start~

KILOPASCAL

1 @ 850

4 @ 3000

8 @ 5600

Bounces 8-10+ at 6000

From what I've read, 15" of mercury vacuum is the max safe level for performance. This gives a maximum of 2.5" - 3", so it's really for just for venting, but only costs <$30 in parts (already have the air pump anyway).

Left: Vacuum generator, one way valve keeps vacuum stable.

Upper Right: Outlet in fender used existing hole.

Bottom Right: Air jet. 3/16" hole drilled in 1/2" stub out.

Notes:

My air pump (with possibly 110K miles) makes a maximum of about 10 PSI air pressure when plugged.

Makes a puffing noise at idle, similar to an exhaust manifold leak.

No stinky vapors while the heater is on!

*Original Thread*

~thread~start~

Last edited by PorKen; 01-20-2004 at 03:44 AM.

#4

Inventor

Rennlist Member

Rennlist Member

Thread Starter

GlenL,

Not burning vapors:

-Oil vapor lowers octane rating, increases preignition/knocking risk.

-Steam is unburnable, lowers air/fuel volume.

-No oil collection in manifold.

Vacuum in crankcase:

-Rings seal better?

-Less air restriction to piston downstroke at high rpm.

-Oil leaks reduced.

Not burning vapors:

-Oil vapor lowers octane rating, increases preignition/knocking risk.

-Steam is unburnable, lowers air/fuel volume.

-No oil collection in manifold.

Vacuum in crankcase:

-Rings seal better?

-Less air restriction to piston downstroke at high rpm.

-Oil leaks reduced.

#6

Addict

Lifetime Rennlist

Member

Lifetime Rennlist

Member

I wonder how much oil you will be sucking out of the motor into the catch can vs just going to the can without the pump?

Keep an eye on your oil level!

Keep an eye on your oil level!

#7

Inventor

Rennlist Member

Rennlist Member

Thread Starter

shaaark89,

I'm curious too about any additional horsepower at high rpm, although the main purpose for me was to keep the stank out of the cabin! It might be a net zero with the air pump drive loss, but it's helping the engine health overall?

It's vented to the rear upper right side fender well with no catch can. This obviously would not be good for racing, or for cars with plenty of oily blowby. It could just as easily be vented elsewhere, or better, through a catch can.

From what I've read about car aerodynamics, the rear fender well is a low pressure zone at speed, which might aid the suction further.

...

I only have steam and a light oil vapors from the outlet, never any liquid oil.

I suppose one could put some plastic steel wool in the early cars' oil fill 'basket' for extra oil absorbtion.

...

It's funny but I like the look of having the air pump installed, I was never comfortable visually with having all the belts go to one side. I don't know if the crank pulley is more or less stressed with equal loading, but it 'looks' better to me...

I'm curious too about any additional horsepower at high rpm, although the main purpose for me was to keep the stank out of the cabin! It might be a net zero with the air pump drive loss, but it's helping the engine health overall?

It's vented to the rear upper right side fender well with no catch can. This obviously would not be good for racing, or for cars with plenty of oily blowby. It could just as easily be vented elsewhere, or better, through a catch can.

From what I've read about car aerodynamics, the rear fender well is a low pressure zone at speed, which might aid the suction further.

...

I only have steam and a light oil vapors from the outlet, never any liquid oil.

I suppose one could put some plastic steel wool in the early cars' oil fill 'basket' for extra oil absorbtion.

...

It's funny but I like the look of having the air pump installed, I was never comfortable visually with having all the belts go to one side. I don't know if the crank pulley is more or less stressed with equal loading, but it 'looks' better to me...

Trending Topics

#8

Inventor

Rennlist Member

Rennlist Member

Thread Starter

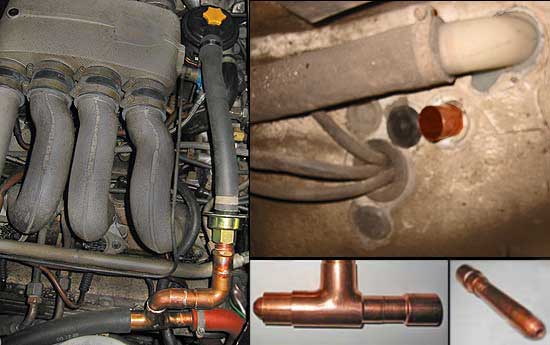

Here's the construction details...

Standard AV7 (air pump check valve)

3/4 heater hose

Copper:

3/4 to 1/2 male pipe adaptor

3/4 90 elbow (optional)

3/4 90 street elbow (optional)

3/4 x 3/4 x 1/2 T

1/2 stub out (closed end pipe for construction)

3/4 x 1/2 reducer

3/4 copper pipe for connections

I drilled a 3/16" hole in the end of the stub.

I filed the restriction in the 1/2 run of the 'T' so the stub would slide all the way through the 'T'.

I soldered all the fittings together with flux-core electrical solder.

It is possible to push 3/4" hose over the oil fill cap connector, which is 1", but it takes patience!

...

The air pump blows through the stub and creates a pressurized stream of air which expands in the hose, pulling the crankcase vapors through the 'T'. I tried running the air jet further inside the 'T', but the best vacuum was with it at the end of the 'T' run.

The air pump pressurizes the air in pulses which makes the vacuum level swing up and down. The check valve keeps the vacuum level stable, but doesn't really hold the vacuum in very long after reducing the rpm.

The elbows aren't really necessary, and I'm probably going to take them off, and have the check valve be closer to the 'T'. I also am going to use 5/8 hose from the oil cap (with adapter) to the check valve to reduce the volume of air.

Standard AV7 (air pump check valve)

3/4 heater hose

Copper:

3/4 to 1/2 male pipe adaptor

3/4 90 elbow (optional)

3/4 90 street elbow (optional)

3/4 x 3/4 x 1/2 T

1/2 stub out (closed end pipe for construction)

3/4 x 1/2 reducer

3/4 copper pipe for connections

I drilled a 3/16" hole in the end of the stub.

I filed the restriction in the 1/2 run of the 'T' so the stub would slide all the way through the 'T'.

I soldered all the fittings together with flux-core electrical solder.

It is possible to push 3/4" hose over the oil fill cap connector, which is 1", but it takes patience!

...

The air pump blows through the stub and creates a pressurized stream of air which expands in the hose, pulling the crankcase vapors through the 'T'. I tried running the air jet further inside the 'T', but the best vacuum was with it at the end of the 'T' run.

The air pump pressurizes the air in pulses which makes the vacuum level swing up and down. The check valve keeps the vacuum level stable, but doesn't really hold the vacuum in very long after reducing the rpm.

The elbows aren't really necessary, and I'm probably going to take them off, and have the check valve be closer to the 'T'. I also am going to use 5/8 hose from the oil cap (with adapter) to the check valve to reduce the volume of air.

Last edited by PorKen; 01-19-2004 at 04:46 AM.

#9

Rennlist Member

Originally posted by Eric Dvorak

Sucking oil vapor into the intake will cause detonation under load and makes for quite a smoke screen.

Sucking oil vapor into the intake will cause detonation under load and makes for quite a smoke screen.

#10

Rennlist Member

Vacuum in crankcase:

-Rings seal better?

-Less air restriction to piston downstroke at high rpm.

-Oil leaks reduced.

And....reduced oil pressure at high crankcase vacuum. Watch out.

(the quote function is not working correctly)

-Rings seal better?

-Less air restriction to piston downstroke at high rpm.

-Oil leaks reduced.

And....reduced oil pressure at high crankcase vacuum. Watch out.

(the quote function is not working correctly)

#11

Drifting

Join Date: Jul 2002

Location: Los Angeles, CA

Posts: 3,348

Likes: 0

Received 0 Likes

on

0 Posts

Explain...

Are you saying that the crankcase pressure is essential in maintaining oil pressure? Isn't that the function of the oil pump?

See, my problem, and the problem of cars under boost, is that if you have excessive crankcase pressure, you have issues like oil leaks on the cam covers, etc... Not to mention blowing oil mist into the intake, which is bad news.

I think the idea of venting the excess pressure is a really good idea.

You have reason to think otherwise?

Are you saying that the crankcase pressure is essential in maintaining oil pressure? Isn't that the function of the oil pump?

See, my problem, and the problem of cars under boost, is that if you have excessive crankcase pressure, you have issues like oil leaks on the cam covers, etc... Not to mention blowing oil mist into the intake, which is bad news.

I think the idea of venting the excess pressure is a really good idea.

You have reason to think otherwise?

#12

Inventor

Rennlist Member

Rennlist Member

Thread Starter

Reduced oil pressure at high vacuum (15" or more), but higher volume.

No danger with my gizmo, it does a decent job of venting though.

If you used a catch can (early cars basically have a built in catch can) it would work better to pull through it. This design doesn't like restrictions on the output side. IE, it pulls better than it pushes.

No danger with my gizmo, it does a decent job of venting though.

If you used a catch can (early cars basically have a built in catch can) it would work better to pull through it. This design doesn't like restrictions on the output side. IE, it pulls better than it pushes.

#13

Inventor

Rennlist Member

Rennlist Member

Thread Starter

Ok, this is the final version. I'm not messing with it any more.

It performs the same, but looks better.

I used a 3/4x1/2x1/2 'T' instead, a short peice of 1" hose, then 5/8" hose, and 7/8" hose out.

It performs the same, but looks better.

I used a 3/4x1/2x1/2 'T' instead, a short peice of 1" hose, then 5/8" hose, and 7/8" hose out.

#14

Rennlist Member

Originally posted by bcdavis

Explain...

Are you saying that the crankcase pressure is essential in maintaining oil pressure? Isn't that the function of the oil pump?

Explain...

Are you saying that the crankcase pressure is essential in maintaining oil pressure? Isn't that the function of the oil pump?

Positive pressure in the crankcase is bad bad bad. I'd think the stock venting to the intake is adequate.

But the catch can on mine is not up to anything more than stock application.

Moroso makes a catch can you can plumb in. Also, venting to a higher flow part of the intake with a vent to a lower flow area (all after the air filter) can draw air out.

#15

Inventor

Rennlist Member

Rennlist Member

Thread Starter

OK, this is really the final version.

I added an expansion chamber made of 1"x3/4" reducer and coupler. This addition quiets the puff, puff, puff sound at idle and reduces fluctuations in the vacuum.

Now it makes a stable 3" mercury of vacuum > 5000 rpm, when the engine is cold, or warming, and just over 2" when warm.

I added an expansion chamber made of 1"x3/4" reducer and coupler. This addition quiets the puff, puff, puff sound at idle and reduces fluctuations in the vacuum.

Now it makes a stable 3" mercury of vacuum > 5000 rpm, when the engine is cold, or warming, and just over 2" when warm.