Variable timing belt tension w/temp - required?

#1

Inventor

Rennlist Member

Rennlist Member

Thread Starter

In pursuit of a variable cam advance mechanism, I'm wondering:

Is there a real need for variable tension associated with engine temperature, or is it an example of over-engineering?

Put another way, are the bi-metal washers on the tensioner piston really necessary? Could the belt tension be fixed and still stay 'in the window' during engine temp cycling?

I've seen other makers engines without this feature...

Is there a real need for variable tension associated with engine temperature, or is it an example of over-engineering?

Put another way, are the bi-metal washers on the tensioner piston really necessary? Could the belt tension be fixed and still stay 'in the window' during engine temp cycling?

I've seen other makers engines without this feature...

#2

Rennlist Member

Timing belts in most cars aren't even half this long.

Hmmmm.... Googled up this formula for Aluminum expansion:

EXPANSION/CONTRACTION = LENGTH IN INCHES x DELTA T x .0000129

So assuming:

36" of aluminum(estimated, 2x distance from crank to cam)

Delta T 200║F

That's 36 X 200 X.0000129 = 0.09288 inches interesting number...

interesting number...

Anyway, let's say a tenth of an inch. Doesn't sound too bad until you figure in the 2x multiplier you need because the belt covers the distance twice. So we're talking .184" difference in slack that is taken up by the tensioner between hot & cold.

Seems like it's worth compensating for. Clever folks in Stuttgart, they wouldn't have added a complex system that served no purpose in such a critical area.

Hmmmm.... Googled up this formula for Aluminum expansion:

EXPANSION/CONTRACTION = LENGTH IN INCHES x DELTA T x .0000129

So assuming:

36" of aluminum(estimated, 2x distance from crank to cam)

Delta T 200║F

That's 36 X 200 X.0000129 = 0.09288 inches

interesting number...

interesting number...Anyway, let's say a tenth of an inch. Doesn't sound too bad until you figure in the 2x multiplier you need because the belt covers the distance twice. So we're talking .184" difference in slack that is taken up by the tensioner between hot & cold.

Seems like it's worth compensating for. Clever folks in Stuttgart, they wouldn't have added a complex system that served no purpose in such a critical area.

#4

Rennlist Member

Join Date: Dec 2002

Location: Southern New England

Posts: 1,975

Likes: 0

Received 0 Likes

on

0 Posts

Aluminum expansion will cause a ~0.25% difference in distance between crank and cam (~1.2 mm over the 18" distance). Whether it would remain in tension tolerance without a spring tensioner device would depend upon the characteristics of the belt. Whether we need such a complex high maintenance oil filled device is a valid question, though. We might be better served by a simple spring and damper assembly which would be replaced with the rollers and belt.

#5

Inventor

Rennlist Member

Rennlist Member

Thread Starter

Thanks very much for the replies.

I see now that the disks must go flatter with temp, to compensate for the increased size of the engine.

...

Ruf,

As I noted, I'm envisioning a variable-with-rpm, 6 degree cam advance device. Starting from 3 degrees retard, and going to 3 degrees advanced. In operation, it would be advanced at low engine speeds, and retarded at high speeds.

To do this I need to change the length of the belt on both sides of the crank gear. The most convenient way that I've thought so far is to replace the tensioner with a hydraulic or electrical operated unit and a sympathetic roller on the driven side.

...

Old & New,

That makes much more sense. Have a pressurized or sprung damper to keep an even tension on the belt, no matter any other variables.

I see now that the disks must go flatter with temp, to compensate for the increased size of the engine.

...

Ruf,

As I noted, I'm envisioning a variable-with-rpm, 6 degree cam advance device. Starting from 3 degrees retard, and going to 3 degrees advanced. In operation, it would be advanced at low engine speeds, and retarded at high speeds.

To do this I need to change the length of the belt on both sides of the crank gear. The most convenient way that I've thought so far is to replace the tensioner with a hydraulic or electrical operated unit and a sympathetic roller on the driven side.

...

Old & New,

That makes much more sense. Have a pressurized or sprung damper to keep an even tension on the belt, no matter any other variables.

#6

Inventor

Rennlist Member

Rennlist Member

Thread Starter

I'm in love with the GT accessory belt tensioner (highlighted in green):

#7

Rennlist Member

I like that too.... couple things to note though:

1) There are 2 tensioners because there are 2 different belts

2) The tensioners seem to have a great deal of travel; this is probably because the accessories are non-critical with respect to belt slippage.

I don't think this would be a good way too go on the 928, since the geometry that I see here would not do anything to prevent skipping belt teeth in the event of backfire. The existing tensioner has very little travel, meaning that if something causes the engine to turn backward, there will be very little reduction in belt tension on the opposite side of the crank.

Having said all that, they DO look very well designed.

As an engineer, I believe simple=good.

D

1) There are 2 tensioners because there are 2 different belts

2) The tensioners seem to have a great deal of travel; this is probably because the accessories are non-critical with respect to belt slippage.

I don't think this would be a good way too go on the 928, since the geometry that I see here would not do anything to prevent skipping belt teeth in the event of backfire. The existing tensioner has very little travel, meaning that if something causes the engine to turn backward, there will be very little reduction in belt tension on the opposite side of the crank.

Having said all that, they DO look very well designed.

As an engineer, I believe simple=good.

D

Trending Topics

#8

Inventor

Rennlist Member

Rennlist Member

Thread Starter

SharkSkin,

I realize that it wouldn't work for the timing belt, but they're sure purdy!

I had not considered a backfire event, thank you for mentioning it.

...

I'm struggling to picture using a spring as a tensioner. It would need to have a constant rate and have a dampener/shock absorber so as to not change the tension too quickly.

Using such a tensioner, if the tension on the driven side were increased (via the advance pulley), the tensioner would reel out more belt, correct?

The advance pulley mechanism would also be sprung, so that the advance shift would be gradual, even if the advance movement itself was not progressive.

This setup would not require a link between the pulleys, which would simply things greatly.

The tensioner spring assembly could conceivably reside in the factory tensioner, in place of the disk pack...

I realize that it wouldn't work for the timing belt, but they're sure purdy!

I had not considered a backfire event, thank you for mentioning it.

...

I'm struggling to picture using a spring as a tensioner. It would need to have a constant rate and have a dampener/shock absorber so as to not change the tension too quickly.

Using such a tensioner, if the tension on the driven side were increased (via the advance pulley), the tensioner would reel out more belt, correct?

The advance pulley mechanism would also be sprung, so that the advance shift would be gradual, even if the advance movement itself was not progressive.

This setup would not require a link between the pulleys, which would simply things greatly.

The tensioner spring assembly could conceivably reside in the factory tensioner, in place of the disk pack...

#9

Rennlist Member

I've worked with variable timing systems... in electronic assembly robots.

I've seen some pretty neat stuff. I did see something like what you are talking about; Timing of some driven elements were adjusted by moving a pair of rollers (which were fixed relative to one another) back and forth along the belt path. Here's a rough sketch:

In my example, there is no "tensioner" per se. While I have sort of paraphrased in my drawing, I have seen this concept used to solve a problem exactly like what you are describing. I've given no thought as to how to actually engineer this sort of thing into the 928 motor(no trivial thing to engineer), but maybe it will give you some ideas.

D

I've seen some pretty neat stuff. I did see something like what you are talking about; Timing of some driven elements were adjusted by moving a pair of rollers (which were fixed relative to one another) back and forth along the belt path. Here's a rough sketch:

In my example, there is no "tensioner" per se. While I have sort of paraphrased in my drawing, I have seen this concept used to solve a problem exactly like what you are describing. I've given no thought as to how to actually engineer this sort of thing into the 928 motor(no trivial thing to engineer), but maybe it will give you some ideas.

D

#10

Inventor

Rennlist Member

Rennlist Member

Thread Starter

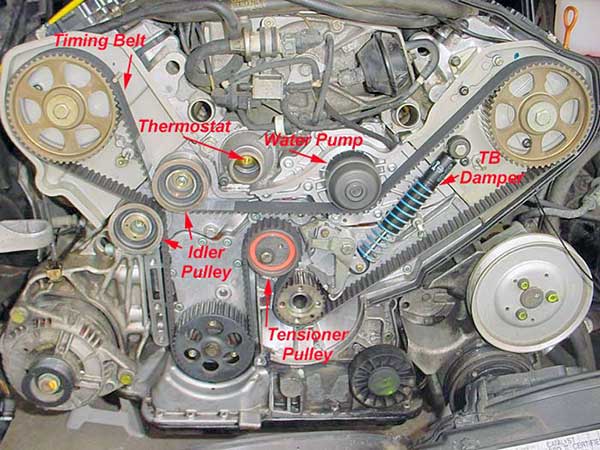

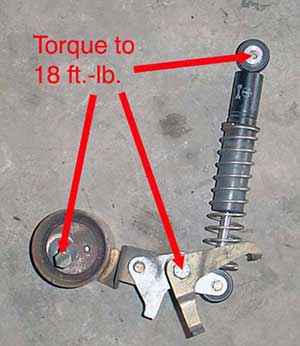

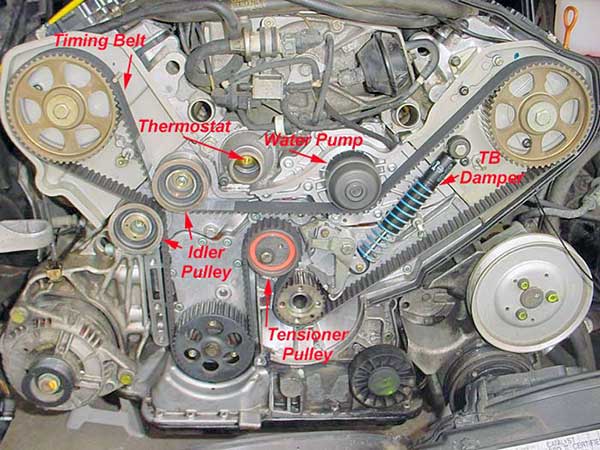

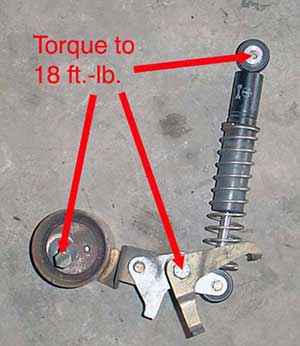

Check out the Audi A8 4.2 engine and tensioner:

www.audipages.com

That (gas charged?) dampener was exactly what I was thinking about.

...

In researching the variable advance, I found a static BMW timing belt tensioner pulley that is only about $20! It looks to be much easier to install and setup than the SAAB pulley I'm using presently, besides $40 cheaper. I am going to rework my fixed cam advance bracket to use this pulley.

www.audipages.com

That (gas charged?) dampener was exactly what I was thinking about.

...

In researching the variable advance, I found a static BMW timing belt tensioner pulley that is only about $20! It looks to be much easier to install and setup than the SAAB pulley I'm using presently, besides $40 cheaper. I am going to rework my fixed cam advance bracket to use this pulley.

Last edited by PorKen; 03-19-2004 at 02:33 AM.

#11

Rennlist Member

I have no idea how you would use that mechanism to alter cam timing but I have no doubt you will have the solution 80% ironed out and welded up, with pictures posted in the next 5 days or so...

D

D

#12

Rennlist Member

Join Date: Dec 2002

Location: Southern New England

Posts: 1,975

Likes: 0

Received 0 Likes

on

0 Posts

Originally posted by PorKen

That (gas charged?) dampener was exactly what I was thinking about.

That (gas charged?) dampener was exactly what I was thinking about.

What's the service interval on the A8, and I wonder if they use the new formulation rubber in the belt?

#13

Inventor

Rennlist Member

Rennlist Member

Thread Starter

SharkSkin,

Normally I would have it 99% done in 2!

I think things through, backward and forward/cheaper and easier, for weeks. So when I actually make something, it goes really quick.

But I have a new project that's chewing up my time. I was lucky enough to find the manual on eBay, though:

...

Old & New,

I keep finding that it's more like: 'there are no new ideas, just new applications'.

It has a 90K belt change interval!

Normally I would have it 99% done in 2!

I think things through, backward and forward/cheaper and easier, for weeks. So when I actually make something, it goes really quick.

But I have a new project that's chewing up my time. I was lucky enough to find the manual on eBay, though:

...

Old & New,

I keep finding that it's more like: 'there are no new ideas, just new applications'.

It has a 90K belt change interval!