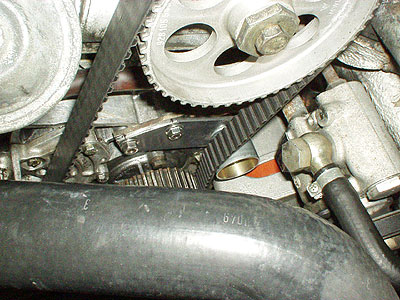

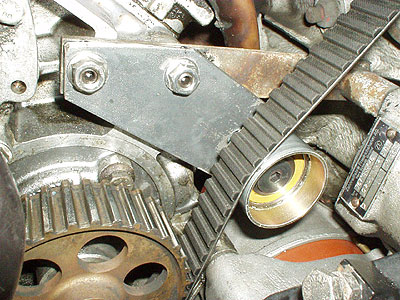

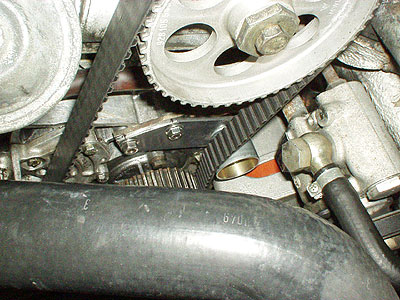

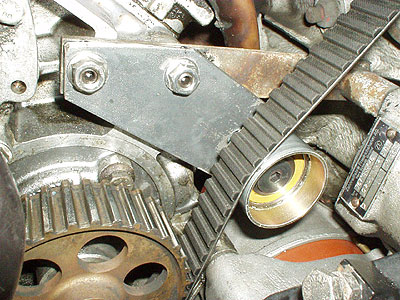

16V adjustable cam timer *installed*

#1

Inventor

Rennlist Member

Rennlist Member

Thread Starter

Sa-weeet.

2 degrees advance (1 cam) to center the cam marks (split the difference), reset the ignition advance. Revs faster, exhaust note is slightly louder. I'm guessing this is how it should have been 'off the boat'.

4 more (2 cam), reset the ignition advance again. Revs real nice. Sounds hungry.

Go for a drive. No torque converter lag. None. Period. Nope.

Mo' pedal, mo' faster.

*Original Thread* *Update*

~thread~start~

2 degrees advance (1 cam) to center the cam marks (split the difference), reset the ignition advance. Revs faster, exhaust note is slightly louder. I'm guessing this is how it should have been 'off the boat'.

4 more (2 cam), reset the ignition advance again. Revs real nice. Sounds hungry.

Go for a drive. No torque converter lag. None. Period. Nope.

Mo' pedal, mo' faster.

*Original Thread* *Update*

~thread~start~

Last edited by PorKen; 10-30-2003 at 01:48 AM.

#3

Addict

Lifetime Rennlist

Member

Lifetime Rennlist

Member

I dunno, i dont get it? It just looks like an idler pulley placing more tension on the belt? How would this item change the timing?

Am i missing some relationship here?

Am i missing some relationship here?

#4

Inventor

Rennlist Member

Rennlist Member

Thread Starter

Sorry, had to drive some mo'.

Tony - it took me quite a bit of figuring to picture this too!

The idler pulley changes the length of the belt between the cam and the right pulley. Normally it's fixed, and the cam marks line up with TDC.

If you create more distance between the crank pulley and the cam pulley, it advances the cam timing, the same as if you put one tooth off on the cam pulley, but one tooth is 15 degrees advance at the crank, or 7.5 degrees at the camshaft, which is too much advance. (You lose power if advanced too much, and too much advance on on interference engine risks hitting the valves.)

More advance creates more dynamic compression, because the intake valve opens and closes sooner. This makes more torque. It is actually moving the torque peak down a few hundred RPM, so you are trading power from the top end for more power down low, where it is more useful for normal driving.

It is said to be more effective for the automatics, because of the way the torque converter works.

Putting in a big gnarly exhaust system will usually raise the torque peak and low speed power suffers.

Retarding the cam timing can give more top end power so ideally the system would be variable.

You have to reset the ignition timing because the distributor is run off the cam, and must be reset to correspond with the piston position, irregardless of the cam timing.

The 16V engines are somewhat imprecise in regards to cam timing, because the cam timing is not adjustable like the 32V engines. As the belt stretches over time, or if you mill the heads, the length of the belt changes, which changes the timing slightly.

I made this test rig to see if it would make any difference on my car, with a 3" exhaust, no cat, open airbox, etc. So I dialed in a few degrees, and sh*t howdy, it just growls and launches when you push the wow pedal now. I'm still experimenting with the setting, but I'm not going over 6 degrees (3 cam) until I can take some proper measurements.

Tony - it took me quite a bit of figuring to picture this too!

The idler pulley changes the length of the belt between the cam and the right pulley. Normally it's fixed, and the cam marks line up with TDC.

If you create more distance between the crank pulley and the cam pulley, it advances the cam timing, the same as if you put one tooth off on the cam pulley, but one tooth is 15 degrees advance at the crank, or 7.5 degrees at the camshaft, which is too much advance. (You lose power if advanced too much, and too much advance on on interference engine risks hitting the valves.)

More advance creates more dynamic compression, because the intake valve opens and closes sooner. This makes more torque. It is actually moving the torque peak down a few hundred RPM, so you are trading power from the top end for more power down low, where it is more useful for normal driving.

It is said to be more effective for the automatics, because of the way the torque converter works.

Putting in a big gnarly exhaust system will usually raise the torque peak and low speed power suffers.

Retarding the cam timing can give more top end power so ideally the system would be variable.

You have to reset the ignition timing because the distributor is run off the cam, and must be reset to correspond with the piston position, irregardless of the cam timing.

The 16V engines are somewhat imprecise in regards to cam timing, because the cam timing is not adjustable like the 32V engines. As the belt stretches over time, or if you mill the heads, the length of the belt changes, which changes the timing slightly.

I made this test rig to see if it would make any difference on my car, with a 3" exhaust, no cat, open airbox, etc. So I dialed in a few degrees, and sh*t howdy, it just growls and launches when you push the wow pedal now. I'm still experimenting with the setting, but I'm not going over 6 degrees (3 cam) until I can take some proper measurements.

Last edited by PorKen; 10-21-2003 at 01:06 AM.

#5

Inventor

Rennlist Member

Rennlist Member

Thread Starter

Notes:

I have another design which would allow for the retention of the covers, but I wanted to see if it would be worth it.

This does not change the tension on the belt, the tensioner operates as normal.

In order to create the extra length on the pulling side, I backed off the tensioner and rotated the crank counter-clockwise slightly; the cams stayed at their marks. Then I reset the tension using the Kempf tool.

There is only maybe a few more degrees adjustment, given the length of the belt.

I like this idea better than using offset cam/crank keys as it is adjustable for age, etc., without having to disassemble anything.

I have another design which would allow for the retention of the covers, but I wanted to see if it would be worth it.

This does not change the tension on the belt, the tensioner operates as normal.

In order to create the extra length on the pulling side, I backed off the tensioner and rotated the crank counter-clockwise slightly; the cams stayed at their marks. Then I reset the tension using the Kempf tool.

There is only maybe a few more degrees adjustment, given the length of the belt.

I like this idea better than using offset cam/crank keys as it is adjustable for age, etc., without having to disassemble anything.

#7

Inventor

Rennlist Member

Rennlist Member

Thread Starter

Old & New,

There are 24 slots on the crank pulley, 48 on the cam (on both the square and round shaped designs). That makes one tooth/notch equal to 15 degrees advance or retard on the crank pulley, or 7.5 degrees on the camshaft pulley.

I moved it 4 to 6 at the crank, or 2 to 3 at the cam. I'm unsure because the cam marks don't line up with the TDC mark on the balancer exactly.

I'm imagining it's now 2 degrees cam over stock.

Many aftermarket cam suppliers recommend 2-3 degrees cam advance for more low/mid range power. Some say no more than 5 degrees advance or retard cam for valve safety. YMMV.

There are 24 slots on the crank pulley, 48 on the cam (on both the square and round shaped designs). That makes one tooth/notch equal to 15 degrees advance or retard on the crank pulley, or 7.5 degrees on the camshaft pulley.

I moved it 4 to 6 at the crank, or 2 to 3 at the cam. I'm unsure because the cam marks don't line up with the TDC mark on the balancer exactly.

I'm imagining it's now 2 degrees cam over stock.

Many aftermarket cam suppliers recommend 2-3 degrees cam advance for more low/mid range power. Some say no more than 5 degrees advance or retard cam for valve safety. YMMV.

Trending Topics

#8

Rennlist Member

Join Date: Dec 2002

Location: Southern New England

Posts: 1,975

Likes: 0

Received 0 Likes

on

0 Posts

So you went about half of a notch? I wonder how much a whole notch affect your power curve? Since you have a non-interference engine, it wouldn't matter...

#9

Drifting

very interesting, creative and it dosent look dificult either. what about longer term durability? you may need to service the cam belt more frequently.

what about the variable with engine rpm idea??

what about the variable with engine rpm idea??

#10

Inventor

Rennlist Member

Rennlist Member

Thread Starter

drnick - thanks!

I'm not too worried about the belt, with a 30K mile service interval...

Having the covers off, besides looking really cool, makes overall servicing much simpler, and changing the belt is a snap.

I would rather fit a larger pulley, if one would could be made to fit, to reduce the bearing speed and extend it's life.

I was initially planning a variable system. However, after I realized that the ignition timing would have to be variable as well (either mechanically or electronically), I decided to see if it was worth it for the amount of complexity this would require.

There needs to be an additional pulley just before the tensioner to play out the belt as the timing pulley pulls. The pulleys need to be located on a swing arm or connected via linkage.

What to use as an actuator? It has to give pressure gradually to allow the belt to rotate into position smoothly. Perhaps an engine oil pressure driven piston, or a starter solenoid using a spring pressured linkage.

Then there's the control logic and ignition timing retard. Maybe John Speake could figure this one out.

Ideally, the cams would be: retarded at idle for smoothness, advanced for low to mid rpms for torque, and retarded at high rpm for power.

I'm not too worried about the belt, with a 30K mile service interval...

Having the covers off, besides looking really cool, makes overall servicing much simpler, and changing the belt is a snap.

I would rather fit a larger pulley, if one would could be made to fit, to reduce the bearing speed and extend it's life.

I was initially planning a variable system. However, after I realized that the ignition timing would have to be variable as well (either mechanically or electronically), I decided to see if it was worth it for the amount of complexity this would require.

There needs to be an additional pulley just before the tensioner to play out the belt as the timing pulley pulls. The pulleys need to be located on a swing arm or connected via linkage.

What to use as an actuator? It has to give pressure gradually to allow the belt to rotate into position smoothly. Perhaps an engine oil pressure driven piston, or a starter solenoid using a spring pressured linkage.

Then there's the control logic and ignition timing retard. Maybe John Speake could figure this one out.

Ideally, the cams would be: retarded at idle for smoothness, advanced for low to mid rpms for torque, and retarded at high rpm for power.

Last edited by PorKen; 10-21-2003 at 03:09 PM.

#11

Nordschleife Master

there is something they have for the 924/931, it is called a franco cam gear which advances and low to mid and retards in the high end IIRC I might have it backwards, does anyone make them for the 928?

#12

Inventor

Rennlist Member

Rennlist Member

Thread Starter

Lizard931 - hmmm...

Manufacturer: Franco Industries

Installed: Apple Bit's Porsche 924 site (Engine tab, Head Modifications)

Manufacturer: Franco Industries

Installed: Apple Bit's Porsche 924 site (Engine tab, Head Modifications)

Last edited by PorKen; 10-21-2003 at 04:01 PM.

#14

Inventor

Rennlist Member

Rennlist Member

Thread Starter

Luvin' it...

I advanced the ignition timing progressively up to 29 (from stock 23). This is the same amount, 6 degrees, that I had to retard it after the cam adjustment.

Previously I could not go over 23 with the Permantune box.

Performance is even sweeter, downshifts are silky smooth and 60 to 100 is wicked fast.

Somebody check that Franco guy out. Unfortunately (or fortunately? ) factor in a distributorless ignition in the price (example: $600 for a Electromotive DIS).

) factor in a distributorless ignition in the price (example: $600 for a Electromotive DIS).

I advanced the ignition timing progressively up to 29 (from stock 23). This is the same amount, 6 degrees, that I had to retard it after the cam adjustment.

Previously I could not go over 23 with the Permantune box.

Performance is even sweeter, downshifts are silky smooth and 60 to 100 is wicked fast.

Somebody check that Franco guy out. Unfortunately (or fortunately?

) factor in a distributorless ignition in the price (example: $600 for a Electromotive DIS).

) factor in a distributorless ignition in the price (example: $600 for a Electromotive DIS).

#15

Instructor

Join Date: Jun 2001

Location: Pasadena, CA, USA

Posts: 188

Likes: 0

Received 0 Likes

on

0 Posts

The Franco gears need to be removed and lubricated every six months as part of normal maintenance. I don't think they're practical for the 928's timing belt, and in addition, you'd be looking at something like $1200 for the DIS and the two gears.

The variable-timing gears are made for cars with big camshafts that can't fill the cylinders efficiently at lower RPMs. I don't think you'd see much in the way of results for a stock-cammed 928, and certainly not $1200 dollars worth. IMO, you'd be better off putting that money towards a 5.0 shortblock instead.

The variable-timing gears are made for cars with big camshafts that can't fill the cylinders efficiently at lower RPMs. I don't think you'd see much in the way of results for a stock-cammed 928, and certainly not $1200 dollars worth. IMO, you'd be better off putting that money towards a 5.0 shortblock instead.