Factory Turbo Removal Proceedure

#1

Addict

Rennlist Member

Rennlist

Site Sponsor

Rennlist Member

Rennlist

Site Sponsor

Thread Starter

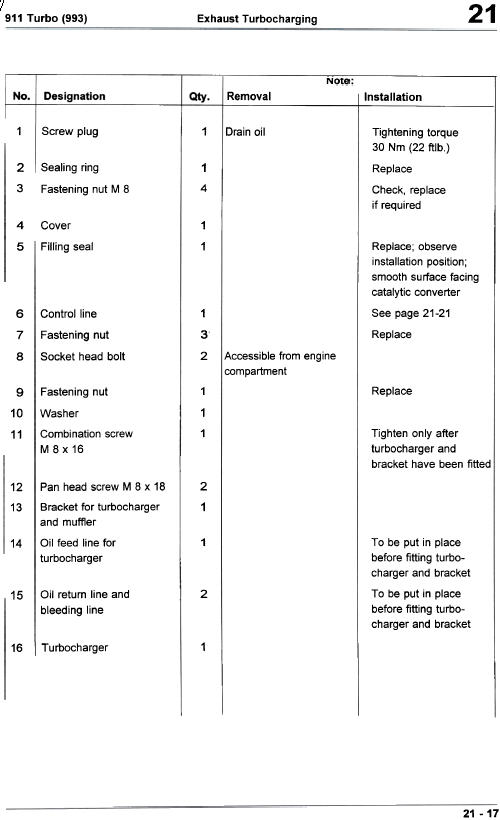

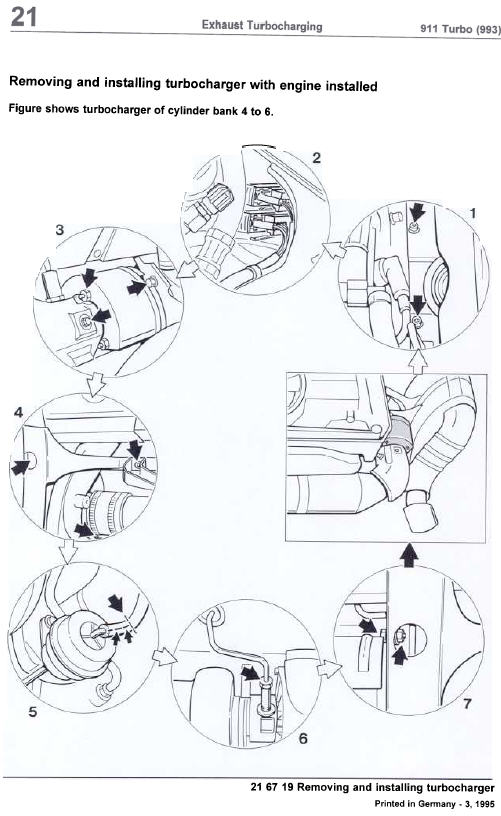

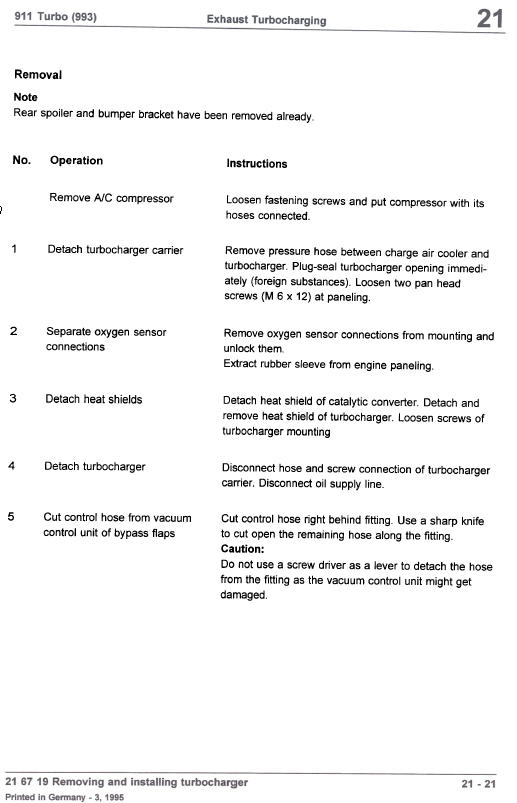

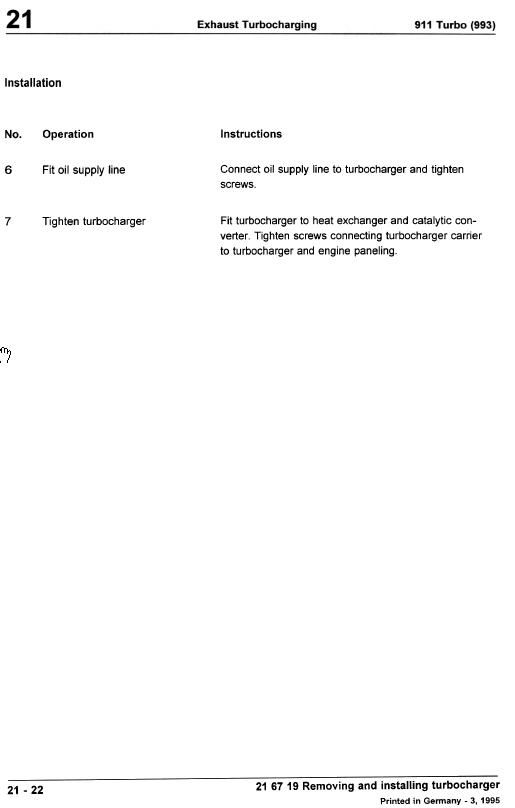

I have scanned the Factory Porsche Repair Manual, which I own. This is for educational purposes only..

#3

Addict

Rennlist Member

Rennlist

Site Sponsor

Rennlist Member

Rennlist

Site Sponsor

Thread Starter

New Turbo Install Procedures

The mindset for all of these procedures is to prolong the life of the turbo’s that you are installing. Many of these tips might be against what you have been taught, and might need to take a little more time to accomplish. I have taken the time to write this tech sheet to prevent unwanted turbocharger failures. Trust me that I have seen all of the short cuts and in the end it will cost you money and the customer money.

First off the engine oil and filter need to be changed. Many times a failed turbo will leave particle in the oil. This will greatly decrease the life of the new turbo’s.

After you have filled the car with new oil. Pull the fuse for the fuel pump #26. You can get lazy and pull the coil to distributor wire, but in the end you’ll pump fuel into the cylinders. Turn the engine over. Watch your oil pressure. Have someone watch the clarity of the oil coming out of the turbo oil supply lines. I usually hang 2 pop cans on the lines and the can tabs will keep them in place. All of this is done prior to re-installing your turbochargers.

Make sure that all the tin above the turbo’s are clean and free from sand or dirt. When connecting the oil supply lines, it never fails to have this debris fall into the turbocharger oil inlet. By the way, if the turbo fails from oil contamination on start up, I will find the debris which will be trapped in the thrust pockets. Neither of us will be happy…

Most of the time your turbo’s have failed due to seals or excessive heat. You will have oil in your intercooler and inlet ducting. Please spend the time to wash all of the hoses with solvent. If you have lost a compressor wheel, you will need to have the intercooler Ultra Sonically cleaned. I will be able to help you, and or make suggestions. Also, check the air filter, you’d be amazed to find oil in there!

Along with all the hoses, you need to spend the time to clean your oil sumps, inside and out.

Please use anti-seize on all of the exhaust studs. When you send your turbo in for the next upgrade in 6 months (SMILE), it will be a lot easier for removal. Also, you can grab some white lithium grease and coat the metal orings. The lithium will carbonize and help everything seal.

Prior to mounting your turbo’s, please pour a small amount of oil into the inlet oil connection. Don’t flood them just get some oil into them and turn the rotating assy over by hand. Another point that I need to mention, Never pull and rock the shaft up and down, you will break the sealing rings, and worse crack the corner of the thrust bearing… To check the bearing play, email me and I’ll send you the procedure for that.

You will need a dial indicator for that….

After everything has been installed and connected, repeat the fuse removal and prime the engine. I like to see full oil pressure. You might need to run a trickle charger. Put the fuse in and start the engine. Check for oil leak from lines… Speaking of lines, NEVER USE SILICONE on any of the lines and do not use pipe dope. IT ALWAYS finds it’s way into the bearings….

Let the car come up to temp and take it out for a test run. Let 30 minutes of no load to pass before putting the coals to it…. Personally if you can baby the turbo’s for 25-100 miles it would be great.. We are trying to seat the sealing rings in and seat the thrust collars.. The attention paid now will reap benefits later.. If you are installing a new ECU and larger turbo’s, it might be nice to log the air fuel ratio…

The mindset for all of these procedures is to prolong the life of the turbo’s that you are installing. Many of these tips might be against what you have been taught, and might need to take a little more time to accomplish. I have taken the time to write this tech sheet to prevent unwanted turbocharger failures. Trust me that I have seen all of the short cuts and in the end it will cost you money and the customer money.

First off the engine oil and filter need to be changed. Many times a failed turbo will leave particle in the oil. This will greatly decrease the life of the new turbo’s.

After you have filled the car with new oil. Pull the fuse for the fuel pump #26. You can get lazy and pull the coil to distributor wire, but in the end you’ll pump fuel into the cylinders. Turn the engine over. Watch your oil pressure. Have someone watch the clarity of the oil coming out of the turbo oil supply lines. I usually hang 2 pop cans on the lines and the can tabs will keep them in place. All of this is done prior to re-installing your turbochargers.

Make sure that all the tin above the turbo’s are clean and free from sand or dirt. When connecting the oil supply lines, it never fails to have this debris fall into the turbocharger oil inlet. By the way, if the turbo fails from oil contamination on start up, I will find the debris which will be trapped in the thrust pockets. Neither of us will be happy…

Most of the time your turbo’s have failed due to seals or excessive heat. You will have oil in your intercooler and inlet ducting. Please spend the time to wash all of the hoses with solvent. If you have lost a compressor wheel, you will need to have the intercooler Ultra Sonically cleaned. I will be able to help you, and or make suggestions. Also, check the air filter, you’d be amazed to find oil in there!

Along with all the hoses, you need to spend the time to clean your oil sumps, inside and out.

Please use anti-seize on all of the exhaust studs. When you send your turbo in for the next upgrade in 6 months (SMILE), it will be a lot easier for removal. Also, you can grab some white lithium grease and coat the metal orings. The lithium will carbonize and help everything seal.

Prior to mounting your turbo’s, please pour a small amount of oil into the inlet oil connection. Don’t flood them just get some oil into them and turn the rotating assy over by hand. Another point that I need to mention, Never pull and rock the shaft up and down, you will break the sealing rings, and worse crack the corner of the thrust bearing… To check the bearing play, email me and I’ll send you the procedure for that.

You will need a dial indicator for that….

After everything has been installed and connected, repeat the fuse removal and prime the engine. I like to see full oil pressure. You might need to run a trickle charger. Put the fuse in and start the engine. Check for oil leak from lines… Speaking of lines, NEVER USE SILICONE on any of the lines and do not use pipe dope. IT ALWAYS finds it’s way into the bearings….

Let the car come up to temp and take it out for a test run. Let 30 minutes of no load to pass before putting the coals to it…. Personally if you can baby the turbo’s for 25-100 miles it would be great.. We are trying to seat the sealing rings in and seat the thrust collars.. The attention paid now will reap benefits later.. If you are installing a new ECU and larger turbo’s, it might be nice to log the air fuel ratio…

#5

Addict

Rennlist Member

Rennlist

Site Sponsor

Rennlist Member

Rennlist

Site Sponsor

Thread Starter

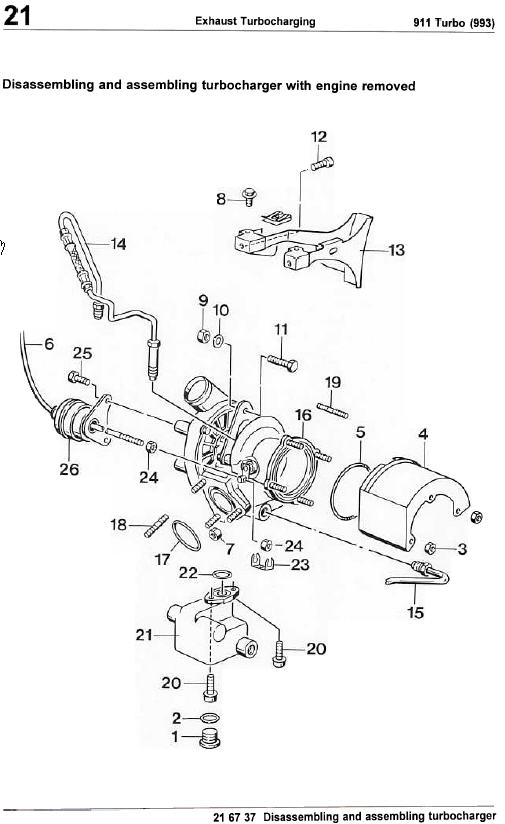

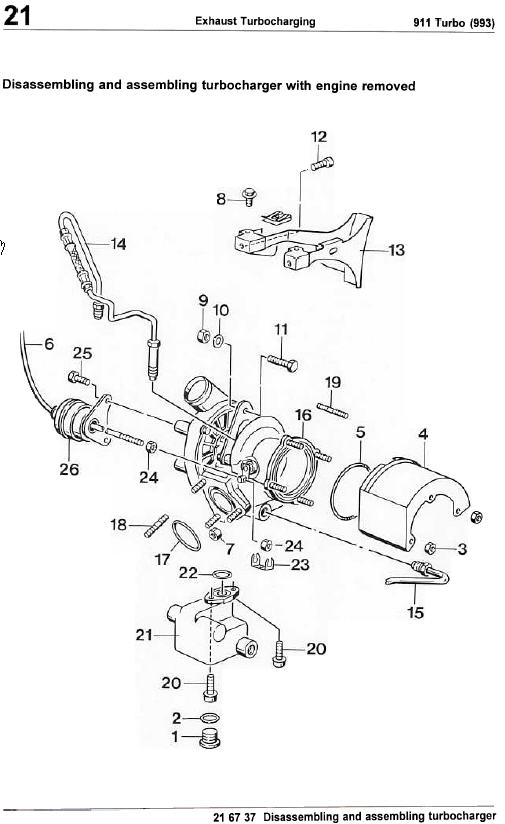

2ea Small Sealing Rings 944 111 205 01

2ea Large Sealing Rings 965 111 205 00

2ea Sump to Turbo Orings 999 701 598 40

2ea Sump Drain Orings 900 123 106 30

14ea Studs 999 061 099 00

4ea Allen Bolts for Sumps 900 067 271 02

2ea Heat Shield 993 123 113 51

14ea Nuts 999 084 627 02

2ea Large Sealing Rings 965 111 205 00

2ea Sump to Turbo Orings 999 701 598 40

2ea Sump Drain Orings 900 123 106 30

14ea Studs 999 061 099 00

4ea Allen Bolts for Sumps 900 067 271 02

2ea Heat Shield 993 123 113 51

14ea Nuts 999 084 627 02

Trending Topics

#8

Addict

Rennlist Member

Rennlist Member

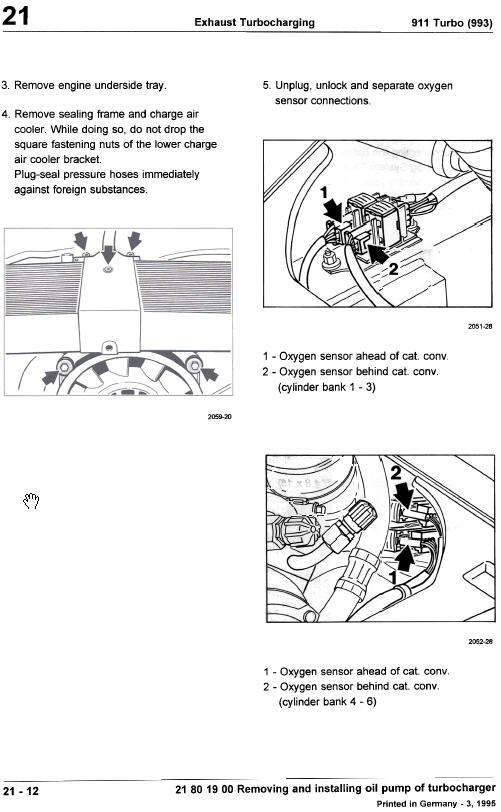

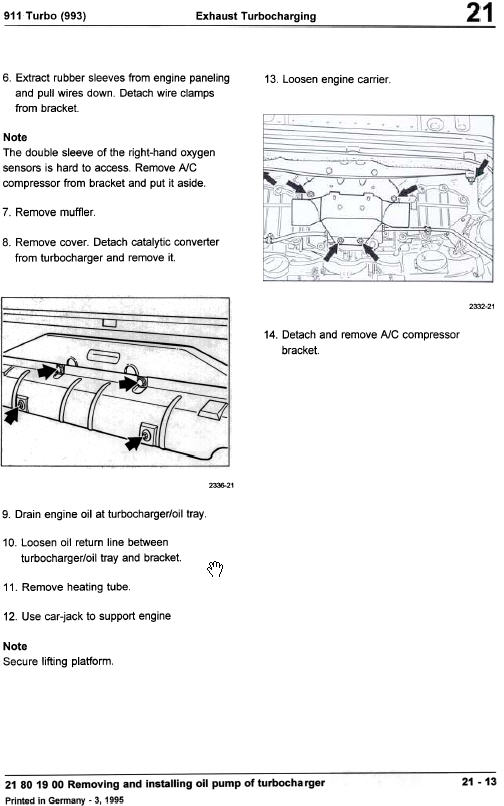

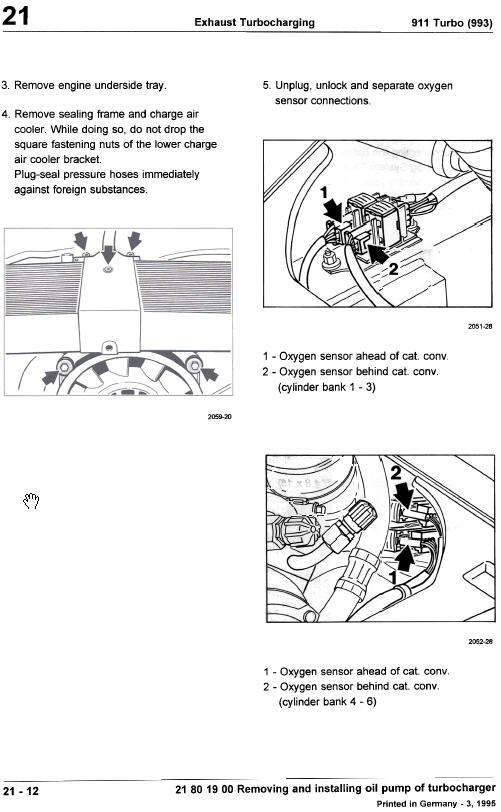

OK. Regarding intercooler removal, Service manual page 21, #4."...do not drop the square fastening nut..." put your hand on the back of the nut while loosening those lower 2 bolts or they WILL drop down into the engine bay...I just dropped down both of them! I just heard a "clink-clunk" after taking out the first bolt....thought "I wonder what that was duh".  On the second bolt, I watched in slow motion as it fell...then it all made sense. Why must I learn everything the hard way?

On the second bolt, I watched in slow motion as it fell...then it all made sense. Why must I learn everything the hard way?

My lovely lady got the out with a parts grabber...what a sweetie!!

Marc

On the second bolt, I watched in slow motion as it fell...then it all made sense. Why must I learn everything the hard way?

On the second bolt, I watched in slow motion as it fell...then it all made sense. Why must I learn everything the hard way?My lovely lady got the out with a parts grabber...what a sweetie!!

Marc

#10

Instructor

Join Date: Feb 2005

Location: SOLD: 1996 TT - Midnight Blue on cashmere

Posts: 109

Likes: 0

Received 2 Likes

on

2 Posts

After a 20 minute drive yesterday and a 2 minute cool down in the driveway, I noticed a small puddle of oil on the driveway. Once I put my '96 TT up on my four-post storage lift, I could see oil had been seeping from high up on the driver's side turbo. The turbo is NOT smoking so it seems that it is an external leak only. Could the oil feed line have come loose? I checked all of the oil lines on the bottom of the turbo and they seem to be fine.

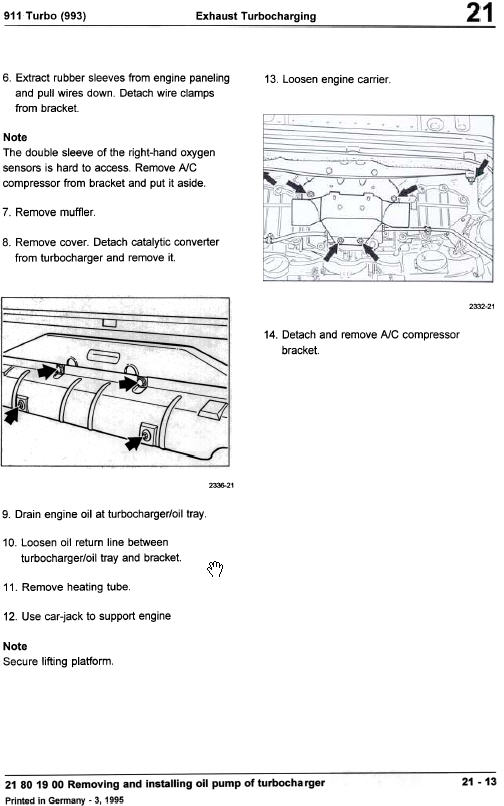

Kevin: thank you so much for your post. Could #14 on page 21 of this link be the culprit? If so, how can you get to it to tighten it?

https://rennlist.com/forums/showthread.php?t=196641

Kevin: thank you so much for your post. Could #14 on page 21 of this link be the culprit? If so, how can you get to it to tighten it?

https://rennlist.com/forums/showthread.php?t=196641

#11

Addict

Rennlist Member

Rennlist

Site Sponsor

Rennlist Member

Rennlist

Site Sponsor

Thread Starter

https://rennlist.com/forums/996-turbo-forum/197896-oil-smoke-at-startup-again.html

There are 4 areas that the oil can be leaking from..

1) Valve cover above the turbocharger.. You need to clean the area of the seal and watch it for oil. We are getting enough miles on these seals that they should be replaced anyway..

2) The oil inlet pipe usually will not seat correctly when one installs new turbochargers and isn't tightened correctly. However, this line gets corroded over the years and requires replacement as well. Springing a leak out of the blue is not usually the case for this hard line.

3) Sump seal between turbocharger and sump tank. This oring can get pinched upon assy, or fail if not lubed prior to assy. Again this usually leaks after an install.

4) The turbocharger will leak from typically two areas. The first sign is from the compressor side (cold) side. Oil will be present in the inlet boot or hose.. If you take it off and you have oil inside, you typically have signs of a turbocharger failure with the exception that I have written below. Advanced wear will show a wet turbine housing. Oil will be dripping off the turbine housing. The bearing housing might ALSO be wet masking the effect of #2.. Regardless, the oil is breaching the turbine side seal and the turbo needs fixed..

The exception to the above steps is high oil levels and improper oil filters installed.. I would not install any oil filters on a TT that did not come directly from a Porsche Dealer.. It is not worth the headache.. Mahle, Bosch, and any other OEM filter have all failed on our cars. Go to the Dealer and purchase Porsche filters in the nice box..

There are 4 areas that the oil can be leaking from..

1) Valve cover above the turbocharger.. You need to clean the area of the seal and watch it for oil. We are getting enough miles on these seals that they should be replaced anyway..

2) The oil inlet pipe usually will not seat correctly when one installs new turbochargers and isn't tightened correctly. However, this line gets corroded over the years and requires replacement as well. Springing a leak out of the blue is not usually the case for this hard line.

3) Sump seal between turbocharger and sump tank. This oring can get pinched upon assy, or fail if not lubed prior to assy. Again this usually leaks after an install.

4) The turbocharger will leak from typically two areas. The first sign is from the compressor side (cold) side. Oil will be present in the inlet boot or hose.. If you take it off and you have oil inside, you typically have signs of a turbocharger failure with the exception that I have written below. Advanced wear will show a wet turbine housing. Oil will be dripping off the turbine housing. The bearing housing might ALSO be wet masking the effect of #2.. Regardless, the oil is breaching the turbine side seal and the turbo needs fixed..

The exception to the above steps is high oil levels and improper oil filters installed.. I would not install any oil filters on a TT that did not come directly from a Porsche Dealer.. It is not worth the headache.. Mahle, Bosch, and any other OEM filter have all failed on our cars. Go to the Dealer and purchase Porsche filters in the nice box..

#12

Kevin,

Your comments are timely. I bought a 97' TT with several upgrades including new GT-2 turbos, installed by TPC.

There was oil dripping from the inlet connection to the intercooler at the hose connection.

If the turbo has failed is there a reliable rebuilt option?

Thanks,

Your comments are timely. I bought a 97' TT with several upgrades including new GT-2 turbos, installed by TPC.

There was oil dripping from the inlet connection to the intercooler at the hose connection.

If the turbo has failed is there a reliable rebuilt option?

Thanks,

#14

Kevin,

Ive been doing some searches regarding running-in procedure to new turbos... can you elaborate a little...

the last thing i want to do is fry the turbos before even giving them a chance to work.

many thanks and appreciation!

Chunn

Ive been doing some searches regarding running-in procedure to new turbos... can you elaborate a little...

the last thing i want to do is fry the turbos before even giving them a chance to work.

many thanks and appreciation!

Chunn

#15

Addict

Rennlist Member

Rennlist

Site Sponsor

Rennlist Member

Rennlist

Site Sponsor

Thread Starter

The last thing is a condition of "lack of lube oil" and in the same condition, air in the oil supply lines. If you have not taken the time to prime the engine over to get oil pressure and to get clean/clear oil, air that is trapped will displace assembly lube. When this happens we have a situation that has metal (rotating assy) turning at high speeds in dry bearings and dry thrust bearing. Hope that helps..