PKVVTS (PorKen Variable Valve Timing System)

#1

Inventor

Rennlist Member

Rennlist Member

Thread Starter

The PorKensioner worked so well, I decided to go with the secondary project. Variable valve timing by changing the belt length on either side of the crank gear.

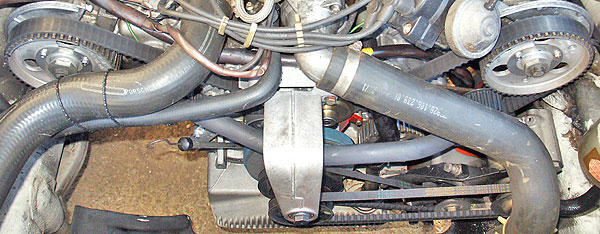

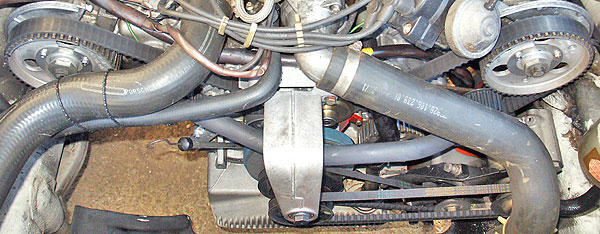

The bar is 3/4 Sch.40 pipe, and at the ends are 968 TB tensioner pulleys. Reusing the fan mount saved me a huge amount of time, and is very solid.

With this first bar, I am able to change the ignition (crank) timing four degrees by pushing down on the left (driver's) side, measured with a digital timing light. That's two cam degrees. I think I can squeeze 6/3 out of it with a little modification.

I'm still not sure about how to engage it - it takes a good amount of force to push the belt. I'm hoping that if I put a heavy spring on it, and get the pressure right, it might be automatic, just by virtue of the engine spinning faster, and exerting more force against the bar.

...

All in all, it's been a very satifying week. I have been scheming, researching, planning, for a couple of years to do these two projects, and they came together in four days!

The bar is 3/4 Sch.40 pipe, and at the ends are 968 TB tensioner pulleys. Reusing the fan mount saved me a huge amount of time, and is very solid.

With this first bar, I am able to change the ignition (crank) timing four degrees by pushing down on the left (driver's) side, measured with a digital timing light. That's two cam degrees. I think I can squeeze 6/3 out of it with a little modification.

I'm still not sure about how to engage it - it takes a good amount of force to push the belt. I'm hoping that if I put a heavy spring on it, and get the pressure right, it might be automatic, just by virtue of the engine spinning faster, and exerting more force against the bar.

...

All in all, it's been a very satifying week. I have been scheming, researching, planning, for a couple of years to do these two projects, and they came together in four days!

#6

Rennlist Member

Nice approach: I think you will need a hydraulic actuator to position the assembly and ditch the spring idea - the dynamics of the TB will set up a resonance in any spring controlled mechanism and cause the belt to be tossed

The mechanism needs some form of input on engine load vs rpm to activate rather than oil pressure - that will be a fun step ...

The mechanism needs some form of input on engine load vs rpm to activate rather than oil pressure - that will be a fun step ...

#7

Electron Wrangler

Lifetime Rennlist

Member

Lifetime Rennlist

Member

Ken - when you mentioned the PorKen variable timing - i thought you were thinking along these lines... Great - I love the mechanical simplicity of the idea (well until you get into how to drive it and control it - anyway)

For the number of degrees advance/retard you can achieve on the cams with this based on belt movement I assume you pick up some extra slack between the two rollers so it would be more than you'd get by moving just a tensioned stock belt - and your auto tension roller is perfect to allow this movement! Indeed an excellent week!

Keep us posted on developments - I know you will.

Do you have any goals for how much advance/retard you like to get (to run with) and and under what conditions...

Assume this is going to vary quite a bit depending on what cams are in the car and since you have to vary intake & exhast together you have to stop at the point either limits you - assuming you can get enough movement to hit those limits...?

I guess another approach is to go purely experimental - but to be serious you'd need a dyno weekend. I wonder if Sterling has any thoughts based on his variocam knowledge & cam profile work (the general knowledge variety esp. on limitation of locked camshaft variation vs variable between shafts).

Alan

For the number of degrees advance/retard you can achieve on the cams with this based on belt movement I assume you pick up some extra slack between the two rollers so it would be more than you'd get by moving just a tensioned stock belt - and your auto tension roller is perfect to allow this movement! Indeed an excellent week!

Keep us posted on developments - I know you will.

Do you have any goals for how much advance/retard you like to get (to run with) and and under what conditions...

Assume this is going to vary quite a bit depending on what cams are in the car and since you have to vary intake & exhast together you have to stop at the point either limits you - assuming you can get enough movement to hit those limits...?

I guess another approach is to go purely experimental - but to be serious you'd need a dyno weekend. I wonder if Sterling has any thoughts based on his variocam knowledge & cam profile work (the general knowledge variety esp. on limitation of locked camshaft variation vs variable between shafts).

Alan

Trending Topics

#8

Electron Wrangler

Lifetime Rennlist

Member

Lifetime Rennlist

Member

Ken BTW you talk about hard to push down on the belt...

Does the device only contact one side at a time? do you assume your auto tensioner adjusts the belt tension to compensate...

I thought it would be set to contact both sides at all times with the extremes of actuation being just barely touching either side - so the device is in a neutral mid-balance basd on tension Then the only force needed is that to deflect one side of the belt more (while the other goes basically straight) this way the device operating (moving) creates no net change in belt tension. You just split the tension forces either 50-50 neutral or up to 100-0 full extreme operation. Is that way you have it?

I guess the belt tension forces are still quite high even in neutral balance - so maybe you need some good leverage - like a lever arm a with a screw drive at the end - which would also help to address not moving the device too fast and creating extra dynamic tension effects.

Are you envisioning a 2 position flappy like control or more of a continuously variable drive mechanism?

As you can tell - I like your idea a lot

Alan

Does the device only contact one side at a time? do you assume your auto tensioner adjusts the belt tension to compensate...

I thought it would be set to contact both sides at all times with the extremes of actuation being just barely touching either side - so the device is in a neutral mid-balance basd on tension Then the only force needed is that to deflect one side of the belt more (while the other goes basically straight) this way the device operating (moving) creates no net change in belt tension. You just split the tension forces either 50-50 neutral or up to 100-0 full extreme operation. Is that way you have it?

I guess the belt tension forces are still quite high even in neutral balance - so maybe you need some good leverage - like a lever arm a with a screw drive at the end - which would also help to address not moving the device too fast and creating extra dynamic tension effects.

Are you envisioning a 2 position flappy like control or more of a continuously variable drive mechanism?

As you can tell - I like your idea a lot

Alan

#11

Man of many SIGs

Rennlist Member

Rennlist Member

So there is no concern over putting too much tension on this 7' long belt, that seems to already be somewhat of an achile's heel in the 928?

#12

Inventor

Rennlist Member

Rennlist Member

Thread Starter

Covers are for people who are embarrassed to show their equipment!

In it's neutral state, there is extra belt on the 'slack' side, and the pulley is just touching on the 'tight' side. The bar is unequal length as the pulley on the tight side has to move farther to push out the belt, because of the different belt angles. It was a happy convergence that the fan mount was in a pretty good spot for the pivot, the PorKensioner takes up any small variances. There is only so much belt, and the more deflection I use, the less belt wrap on the crank pulley!

The theory is to move the torque peak with rpm, or flatten the torque output. I found that there's roughly 200rpm movement for each cam degree. Peak torque goes up too, but it's a trade for HP with static advance.

Four variable cam degrees would be great. Say, from three advance, to one retard. But more advance is nice around town, four or five cam degrees will bark the tires from every stoplight.

With my low lift/duration 80-82 US cams, there is only a limited range that's useable. I found that over five cam degrees advance started losing power. I never tried retarding on the dyno, so I don't know if it gives any benefit. With better cams, there should be more of a window? I do have some '79 cams to go in, but I've kinda been waiting to baseline this project with my old cams.

An undampened spring would be bad, and there would always be the stress on the belt, and HP loss from the constant pressure on the tight side. I've thought about using a vacuum solenoid, an oil piston, maybe even a clutch slave, but I think the best might be a linear actuator, with a rpm based controller.

In it's neutral state, there is extra belt on the 'slack' side, and the pulley is just touching on the 'tight' side. The bar is unequal length as the pulley on the tight side has to move farther to push out the belt, because of the different belt angles. It was a happy convergence that the fan mount was in a pretty good spot for the pivot, the PorKensioner takes up any small variances. There is only so much belt, and the more deflection I use, the less belt wrap on the crank pulley!

The theory is to move the torque peak with rpm, or flatten the torque output. I found that there's roughly 200rpm movement for each cam degree. Peak torque goes up too, but it's a trade for HP with static advance.

Four variable cam degrees would be great. Say, from three advance, to one retard. But more advance is nice around town, four or five cam degrees will bark the tires from every stoplight.

With my low lift/duration 80-82 US cams, there is only a limited range that's useable. I found that over five cam degrees advance started losing power. I never tried retarding on the dyno, so I don't know if it gives any benefit. With better cams, there should be more of a window? I do have some '79 cams to go in, but I've kinda been waiting to baseline this project with my old cams.

An undampened spring would be bad, and there would always be the stress on the belt, and HP loss from the constant pressure on the tight side. I've thought about using a vacuum solenoid, an oil piston, maybe even a clutch slave, but I think the best might be a linear actuator, with a rpm based controller.

#13

Inventor

Rennlist Member

Rennlist Member

Thread Starter

There is more stress on the belt, so it will need most likely need replacing more often, even with the auto tensioner. With an automatic movement, the system would only push on the belt while accelerating from low rpm. While cruising, it would be in it's neutral, low stress position.

There is not that much return for the effort and expense, but it's something that's been on my mind.

The PorKensioner is something everyone should have, but the PKVVTS is only for the hard core.

There is not that much return for the effort and expense, but it's something that's been on my mind.

The PorKensioner is something everyone should have, but the PKVVTS is only for the hard core.

#15

Inventor

Rennlist Member

Rennlist Member

Thread Starter

I was just out checking the movement at the cams, and found the same movement, two cam degrees. The movement happens quickly too, within 20 crank degrees, turning by hand.

I noticed another feature of the PorKensioner - no problem turning CCW! (I guess you're not supposed to do it with the factory tensioner, so as to not squish the Bellevilles.)

...

Frank,

The PorKensioner should work on all years. Once I find out the best method to reproduce it, I'll offer it up. I'm not in a big hurry though...I've realized it's more profitable to be not selling anything.

I noticed another feature of the PorKensioner - no problem turning CCW! (I guess you're not supposed to do it with the factory tensioner, so as to not squish the Bellevilles.)

...

Frank,

The PorKensioner should work on all years. Once I find out the best method to reproduce it, I'll offer it up. I'm not in a big hurry though...I've realized it's more profitable to be not selling anything.